Polymerization type phosphorus-containing flame retardant as well as preparation method and application thereof as epoxy resin flame retardant

A phosphorus flame retardant, polymeric technology, applied in the field of polymeric phosphorus-containing flame retardants and their preparation and application as epoxy resin flame retardants, can solve the problems of low thermal stability, easy hydrolysis, difficult processing, etc. , to achieve good compatibility, short reaction time and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

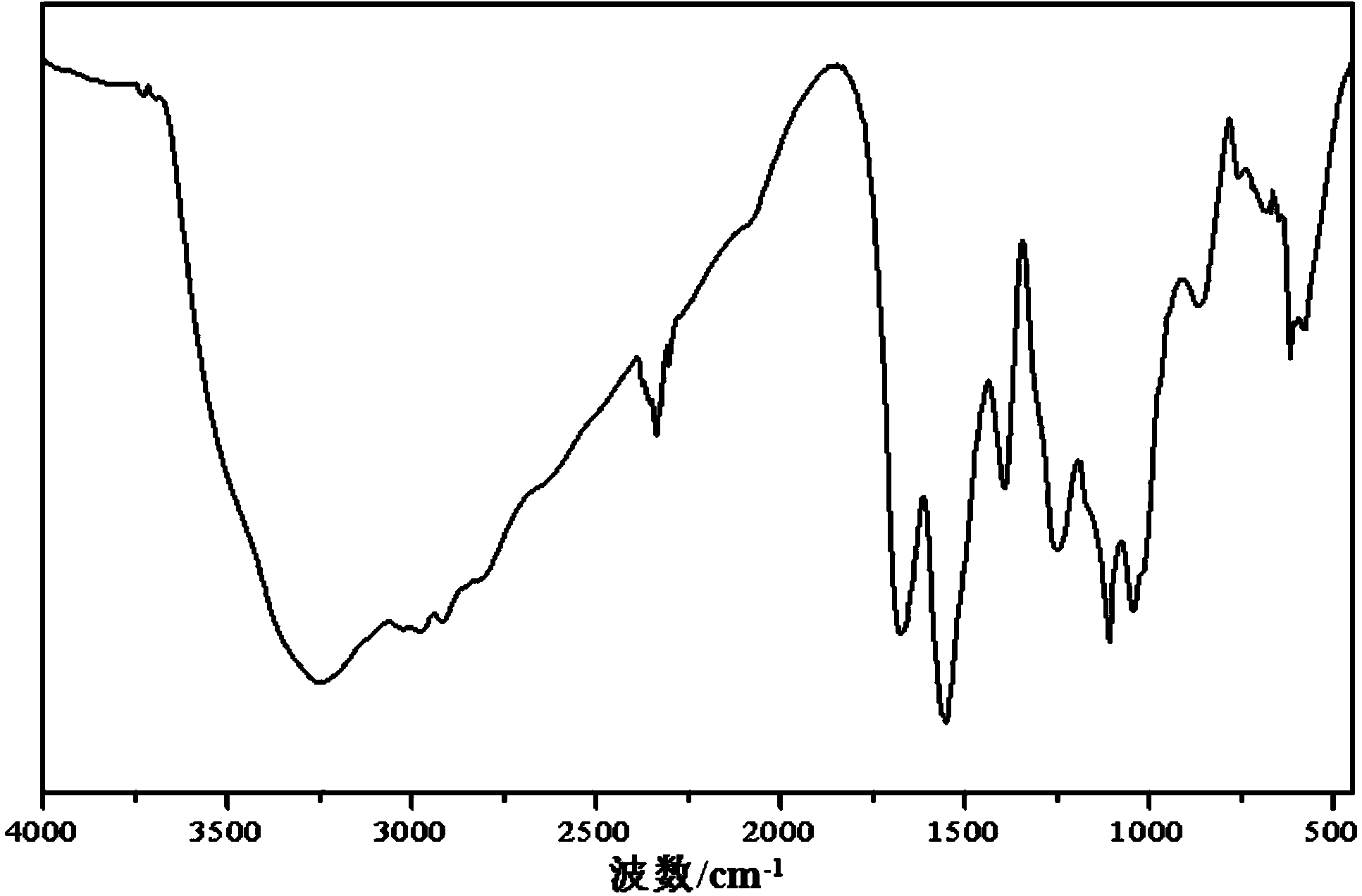

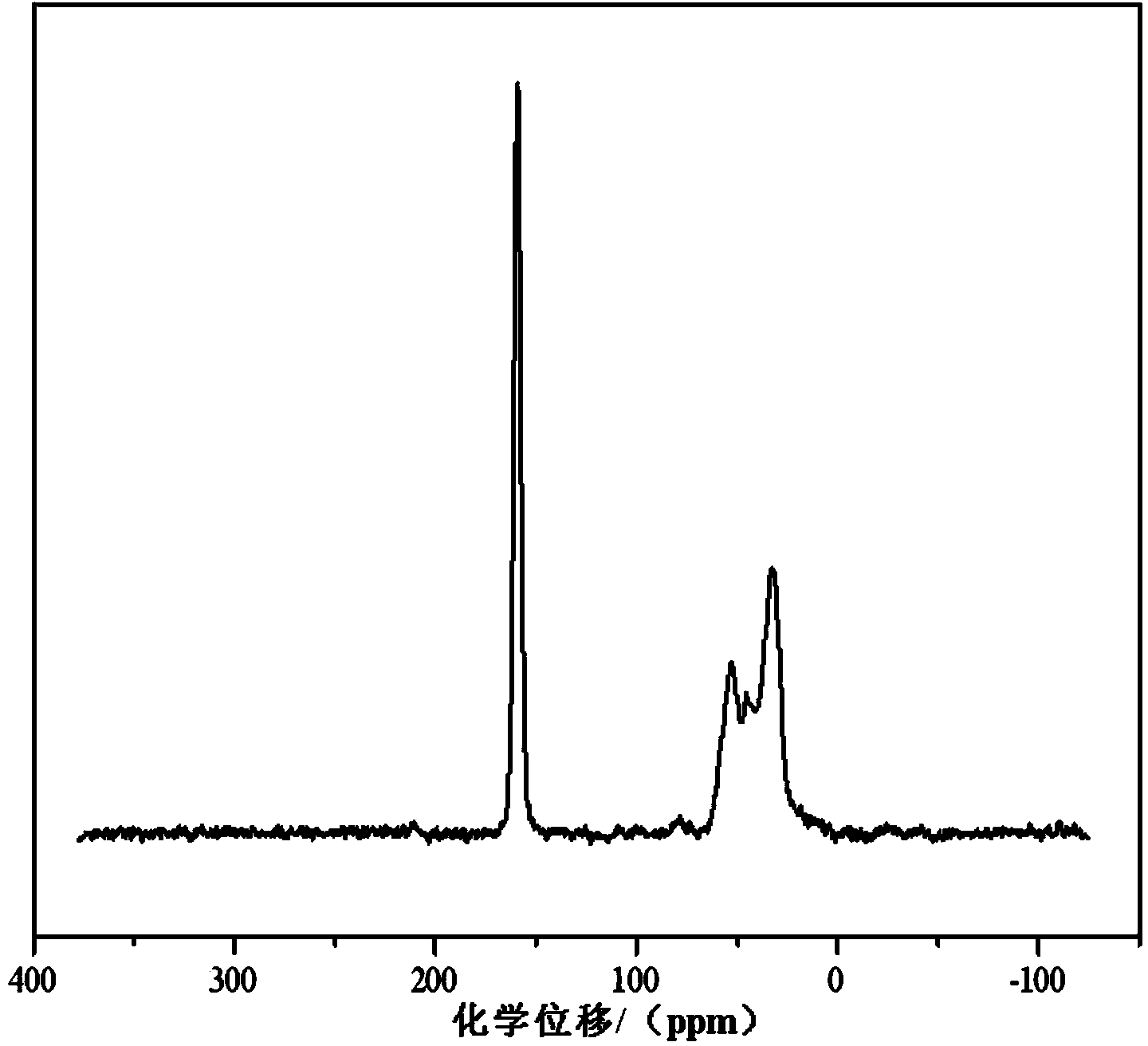

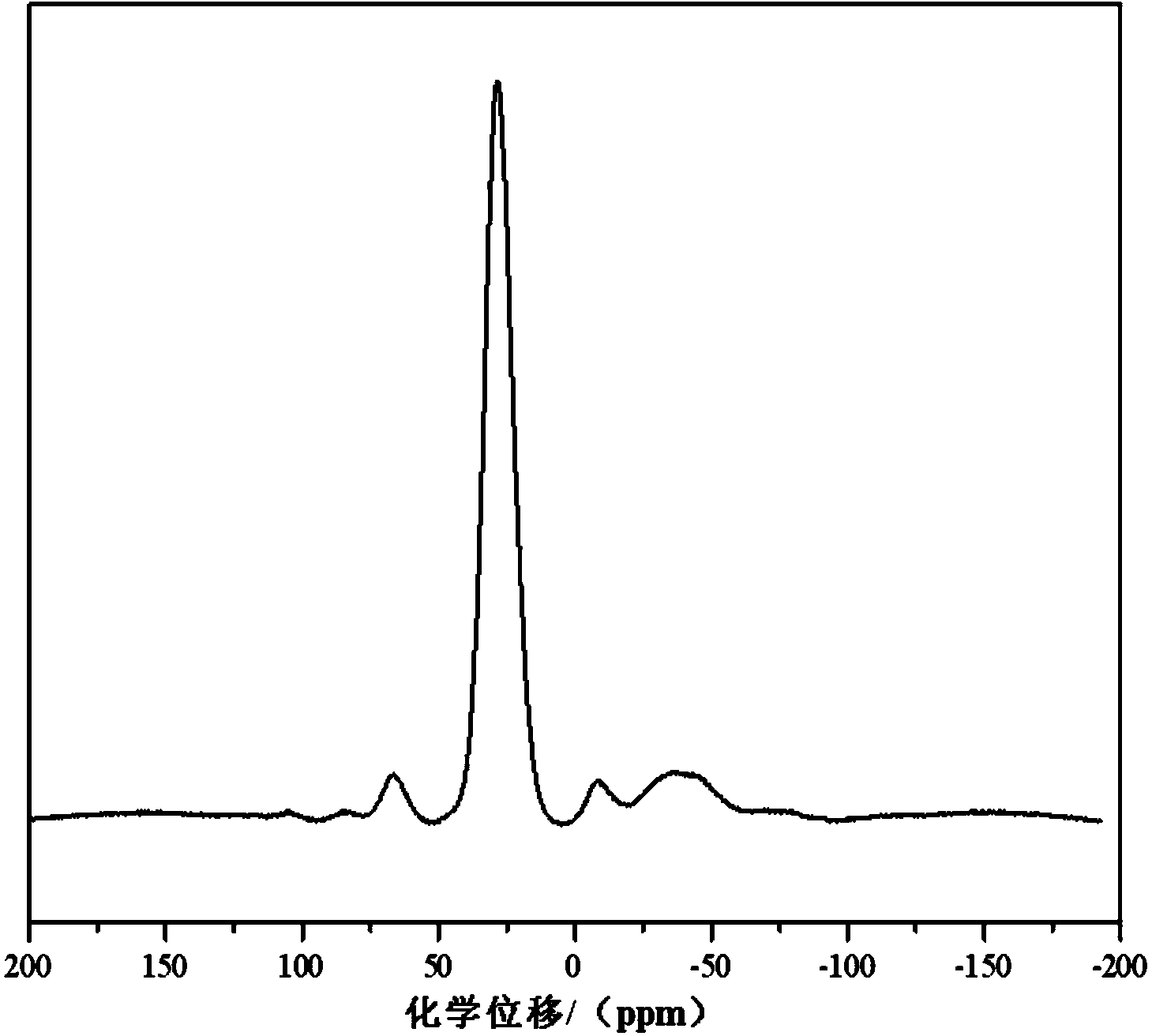

[0030] Specific implementation mode 1: This implementation mode is a polymeric phosphorus-containing flame retardant, and its general structural formula is:

[0031]

specific Embodiment approach 2

[0032] Specific embodiment two: This embodiment is a preparation method of a polymeric phosphorus-containing flame retardant, specifically prepared according to the following steps:

[0033] Adopt water as reaction solvent, take trihydroxymethyl phosphorus oxide aqueous solution as starting material, use phosphoric acid or sulfuric acid as catalyst, add trihydroxymethyl phosphorus oxide aqueous solution, reaction solvent and catalyzer in the reaction vessel at room temperature, then in Add melamine at room temperature, then adjust the pH value to 4-6, stir evenly at a stirring speed of 300r / min-400r / min, and then at a stirring speed of 300r / min-400r / min at a heating rate of 5°C / min from Raise the temperature from room temperature to 85°C-95°C, react at a temperature of 85°C-95°C for 10min-15min, and then raise the temperature from 85°C-95°C to the reflux temperature of the reaction solvent at a temperature of 2°C / min at a temperature increase rate of 2°C / min. The reaction was ...

specific Embodiment approach 3

[0036] Specific embodiment three: This embodiment is a polymeric phosphorus-containing flame retardant, and its general structural formula is:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com