Method for preparing highly-pure phosphoric acid by flow chromatographic crystallization method

A technology of high-purity phosphoric acid and crystallization, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of difficulty in forming an industrial scale, difficult process control, long process flow, etc., and achieve simple operation and high efficiency , the effect of short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

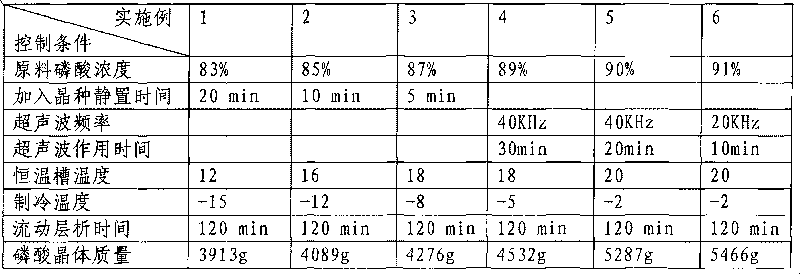

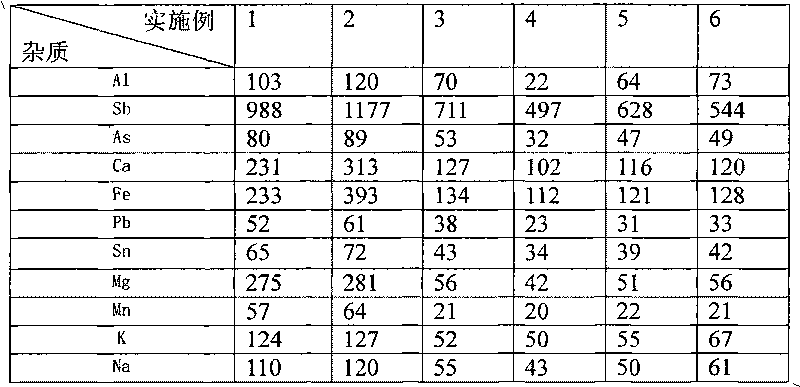

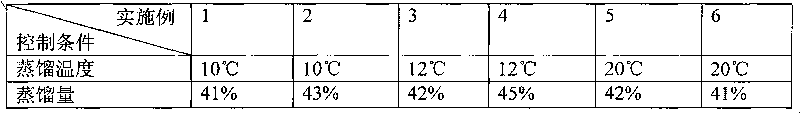

[0020] The method for preparing high-purity phosphoric acid by flow chromatography crystallization of the present invention will be described in detail in the following examples, but is not limited to the examples.

[0021] The phosphoric acid used in the embodiment is prepared by the following method, thermal phosphoric acid (H 3 PO 4 The mass fraction is 92%) after filtering through a 0.2 μm membrane made of polyvinylidene fluoride (PVDF), and then diluted with ultrapure water (18.2 MΩ UP water) to obtain the concentration of raw material phosphoric acid used in each embodiment.

[0022] Flow chromatography crystallization: Use a pump to pump 30Kg of raw phosphoric acid of various concentrations into the phosphoric acid constant temperature tank, set the required constant temperature, and implement flow chromatography crystallization under the following operating and process control conditions to prepare high-purity phosphoric acid. Phosphoric acid hemihydrate crystals are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com