CO2 electrochemical reduction method with Ag-containing electrode as working electrode

A working electrode, electrochemical technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of low reduction current density, low reduction product amount, low Faradaic efficiency, etc., to suppress side reactions, improve product efficiency, prevent negative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

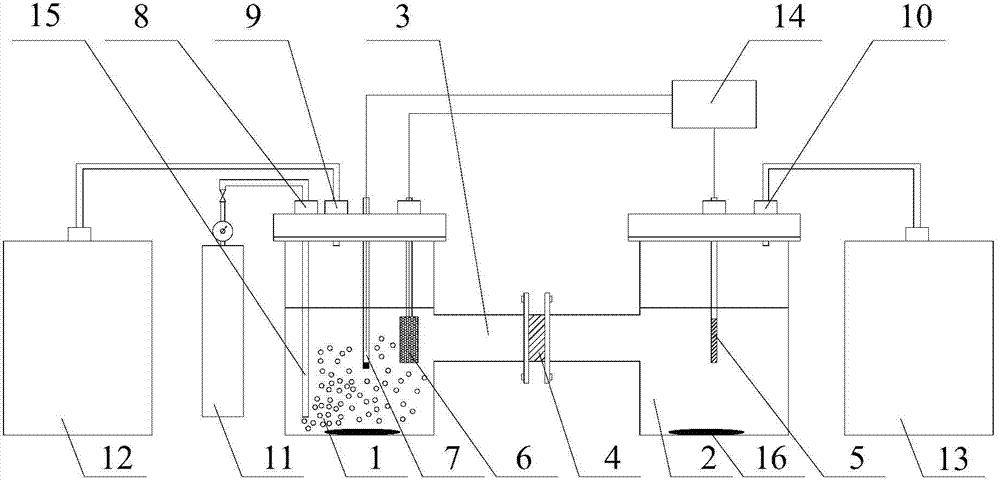

[0015] Specific implementation mode 1: This implementation mode is a CO with an Ag-containing electrode as the working electrode. 2 The electrochemical reduction method is specifically completed according to the following steps: 1. Configure the electrolyte: mix the ionic liquid and ultrapure water to obtain an electrolyte, and the molar fraction of the ionic liquid in the electrolyte is 40%; 2. Equipment assembly: The electrolytic cell of the three-electrode system is arranged in an H shape, that is, the electrolytic cell is divided into an anode pool and a cathode pool, and the anode pool and the cathode pool are connected by a channel. Separated from the anode pool, pour the electrolyte solution into the electrolytic cell of the three-electrode system until the channel between the anode pool and the cathode pool is filled with electrolyte solution, use the platinum sheet as the counter electrode, and place the counter electrode in the three-electrode system. In the anode ar...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the ionic liquid described in step one is BMIM-BF 4 、EMIM-BF 4 、EMIM-NTF 2 , EMIM-DCA, EMIM-EtSO 4 or EMIM-OAC. Others are the same as the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the Ag-containing electrode described in step 2 is an Ag sheet, a porous Ag sheet, an Ag sheet with an AgO oxide film on the surface, or an Ag particle electrode. Or an Ag particle electrode with an AgO film on the surface. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com