Method for reducing and preparing functionalized nano-silver based on polyphenol

A nano-silver and functionalization technology, which is applied in the field of preparation of functionalized nano-silver by polyphenol reduction, can solve the problems of nano-silver morphology and size distribution, single composition, etc., and achieve good monodispersity, high biocompatibility, The effect of scavenging free radicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

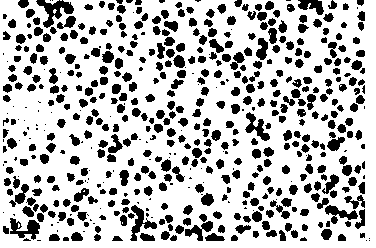

[0024] At room temperature, prepare 6mmol / L silver nitrate solution, 1mmol / L gallic acid solution and 0.02mol / L sodium hydroxide solution. Take 200uL 1mmol / L gallic acid solution and add it to 10mL ultrapure water, mix well, then add 0.02mol / L sodium hydroxide solution to adjust the pH value of the solution to 9.5, then add 200uL 6mmol / L silver nitrate solution to the above alkali In the neutral solution, mix evenly, and react in the dark at 10°C for 30 minutes to obtain a yellow nano-silver solution. The TEM characterization of the samples was as figure 1 As shown, the average particle size is 13nm.

Embodiment 2

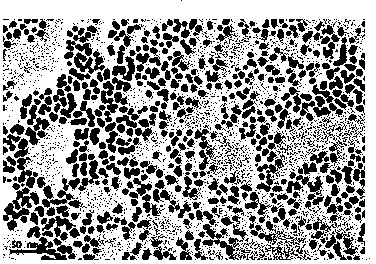

[0026] At room temperature, prepare 1mmol / L silver acetate solution, 6mmol / L protocatechuic acid solution and 0.5mol / L sodium hydroxide solution. Take 200uL 6mmol / L protocatechuic acid solution and add it to 10mL ultrapure water, mix well, then add 0.5mol / L sodium hydroxide solution to adjust the pH value of the solution to 10.5, then add 300uL 1mmol / L silver acetate solution In the above alkaline solution, mix evenly, and react in the dark at 50°C for 10 minutes to obtain a yellow nano-silver solution. The TEM characterization of the samples was as figure 2 As shown, the average particle size is 8.8nm.

Embodiment 3

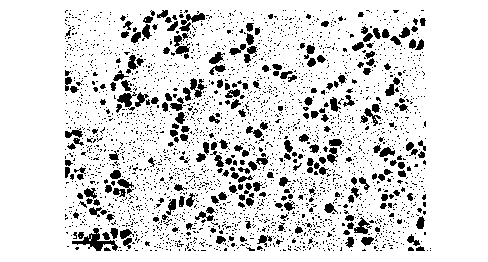

[0028] At room temperature, prepare 12mmol / L silver nitrate solution, 8mmol / L caffeic acid solution and 0.2mol / L potassium hydroxide solution. Take 200uL 8mmol / L caffeic acid solution and add it to 10mL ultrapure water, mix well, then add 0.2mol / L potassium hydroxide solution, adjust the pH value of the solution to 11.5, then add 200uL 12mmol / L silver nitrate solution to the above alkaline solution, mix evenly, and react in the dark at 20°C for 30 minutes to obtain a yellow nano-silver solution. The TEM characterization of the samples was as image 3 As shown, the average particle size is 6.8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com