Method for preparing carbon dots with hydrothermal process on basis of plant leaves

A technology of plant leaves and hydrothermal method, which is applied in the field of preparation of carbon dots by hydrothermal method, can solve the problems of inapplicability to wide application, high cost, complicated treatment, etc., and achieve the effect of easy promotion and use, low cost and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

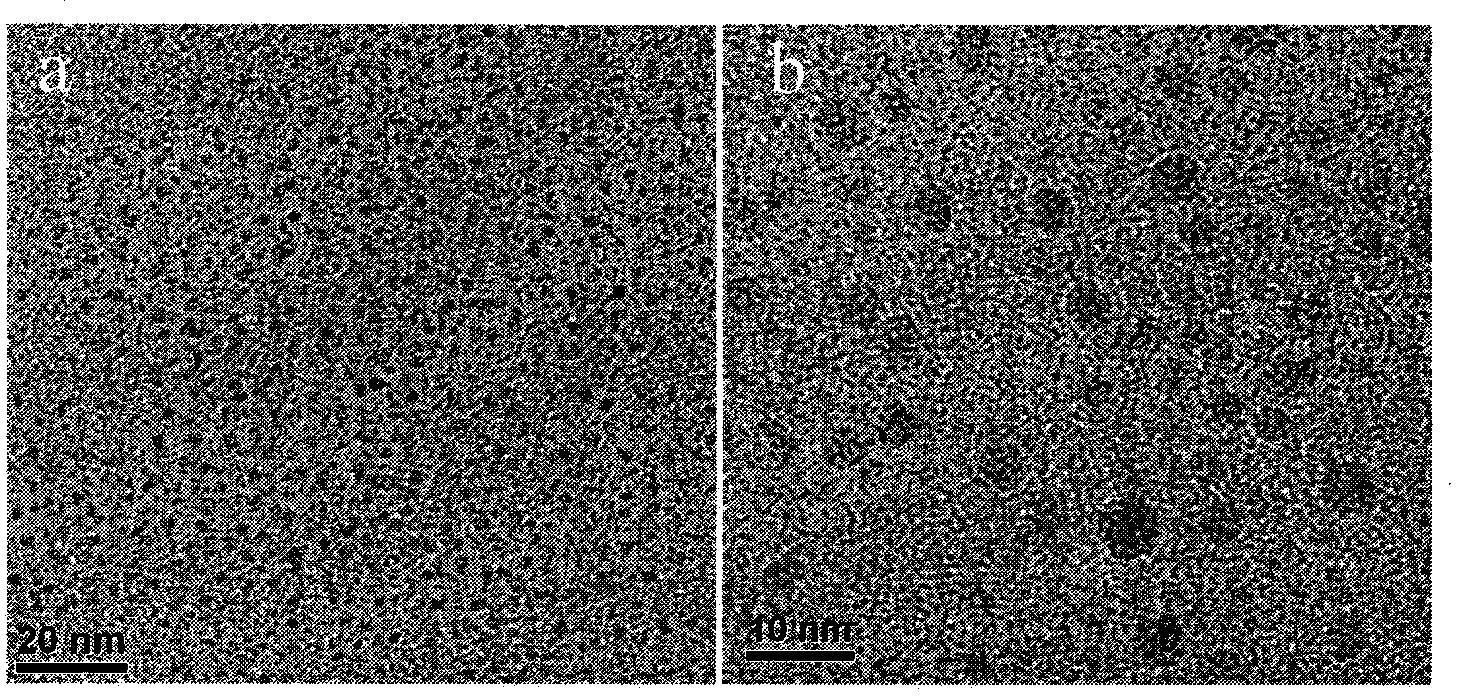

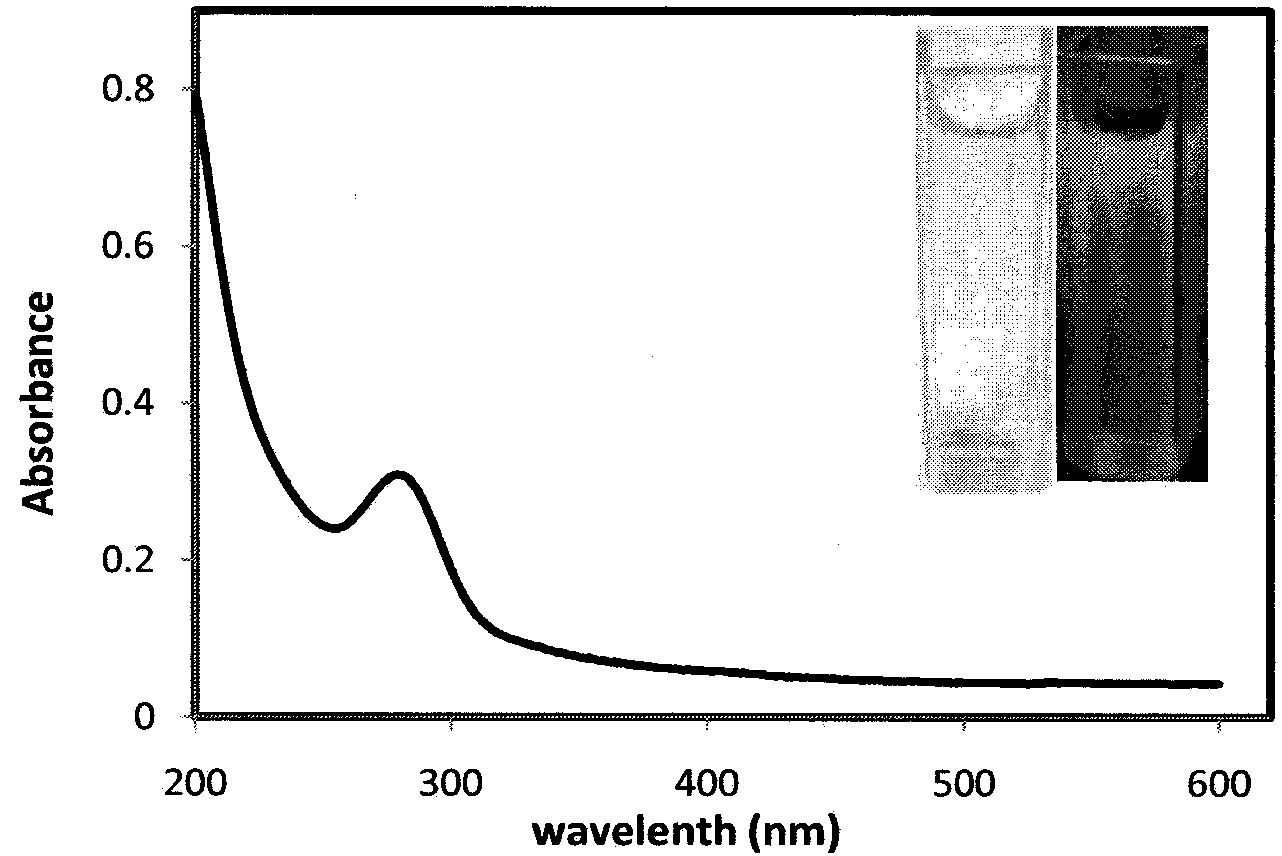

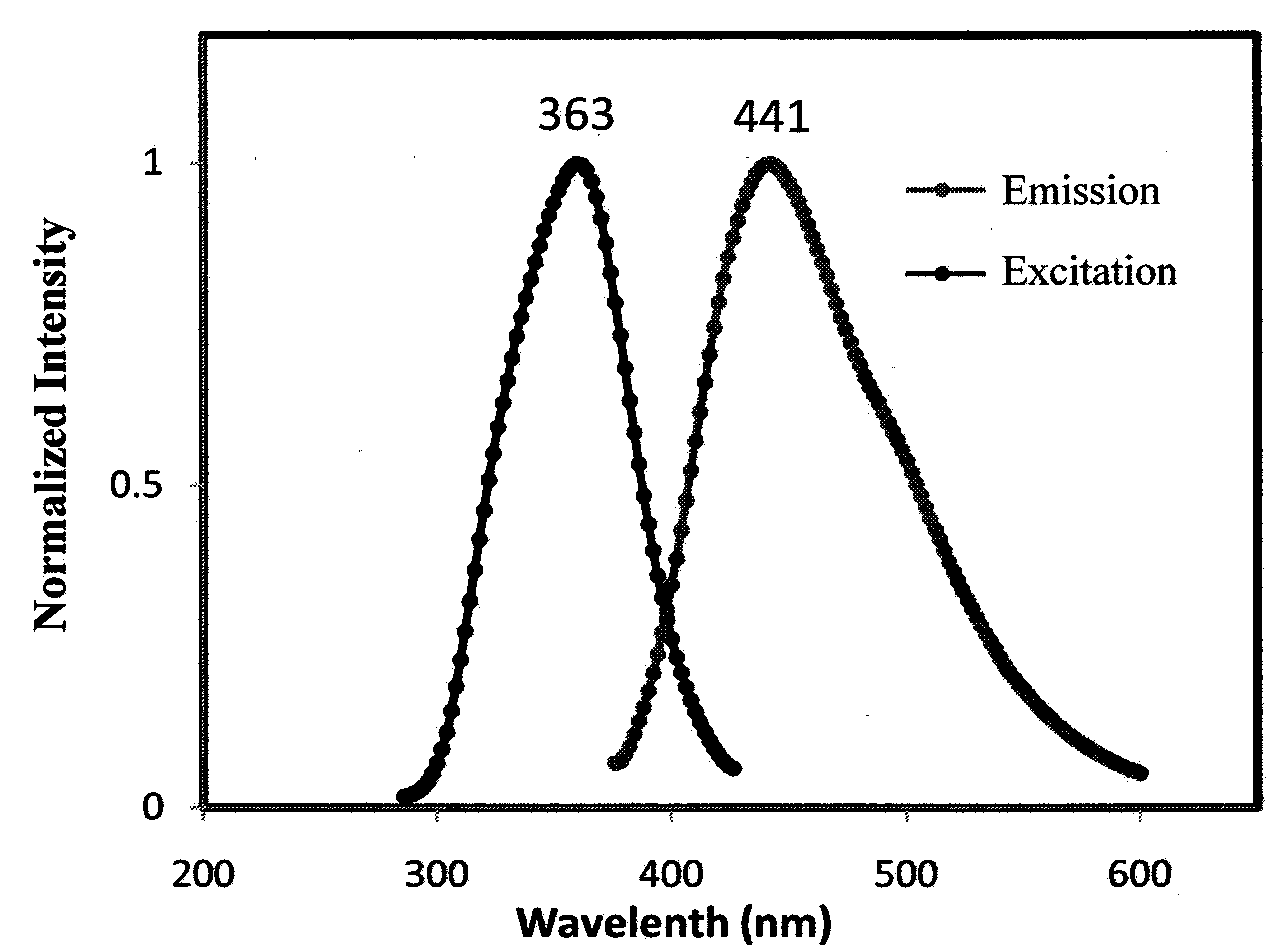

Image

Examples

Embodiment 1

[0027] Weigh 2.58g of washed and dried fresh epiphyllum branches, cut them into pieces, transfer them to a 25mL reaction kettle, add 10mL of water to mix, and conduct a hydrothermal reaction at 180°C for 8.5 hours. After cooling to room temperature, filter to obtain a brownish-yellow liquid, centrifuge at 10krpm for 25min, and take the supernatant.

Embodiment 2

[0029] Weigh 0.38g of washed and dried mint leaves, grind them, transfer them to a 25mL reaction kettle, add 15mL of water and mix well, react in hydrothermal reaction at 180°C for 9 hours, cool to room temperature, filter and centrifuge at 4000rpm for 15min Finally, a brownish yellow liquid was obtained, and the supernatant was dialyzed for 24 hours with a dialysis bag with a molecular weight cut off of 3500, and the dialysate was collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com