Burley tobacco extractive, electronic tobacco juice and tobacco extraction method

A technology of burley tobacco and extract, applied in the field of electronic cigarettes, can solve the problems of lack of tobacco flavor characteristics, weak tobacco flavor characteristics, and impurities in extracted products of electronic cigarette liquid, so as to avoid excessive chemical reaction, increase extraction efficiency, and improve extraction efficiency. The effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

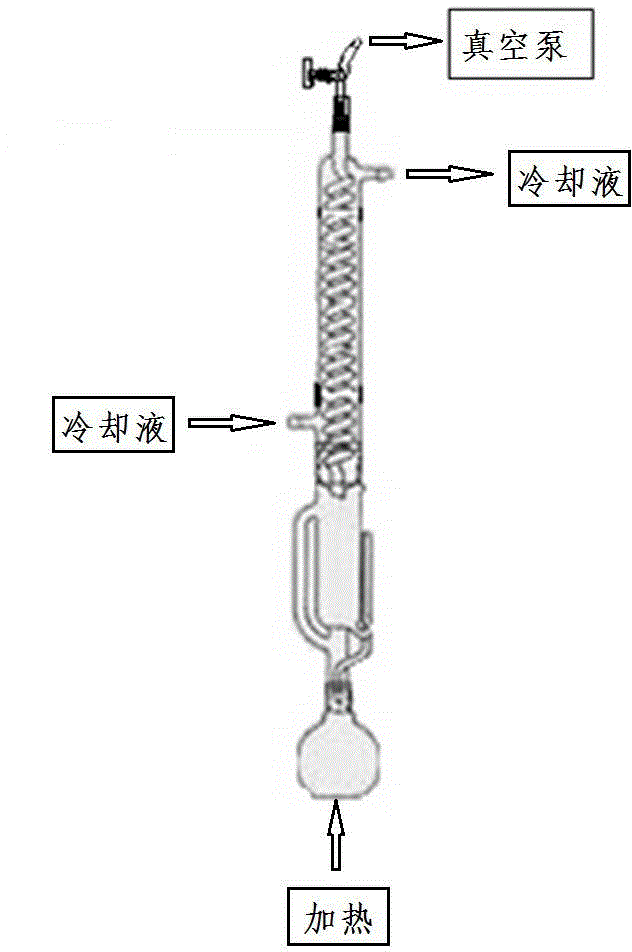

Method used

Image

Examples

Embodiment 1

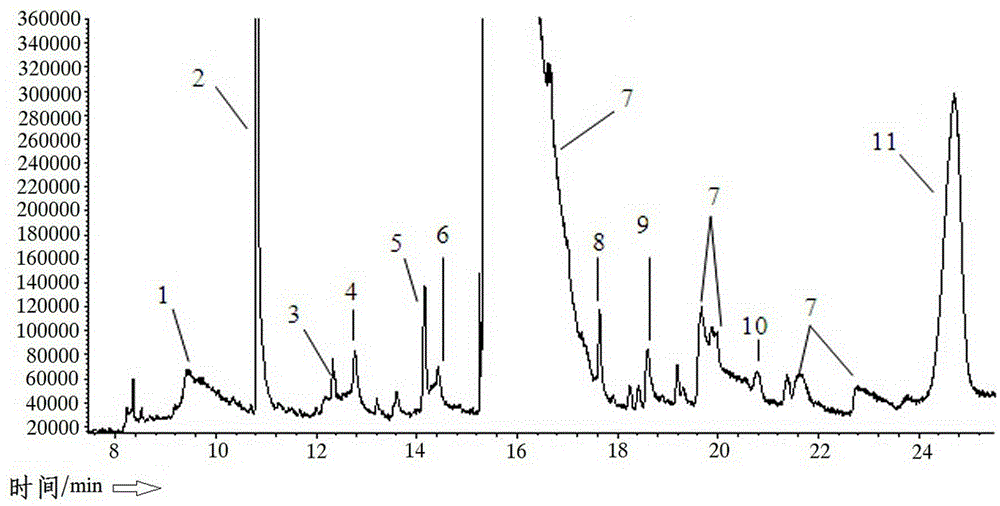

[0034] Take 10g of Burley tobacco S-B3F shredded tobacco and use 200mL of absolute ethanol as the extraction solvent to extract for 3 hours with the improved Soxhlet extraction device of the present invention, the vacuum degree is 40mmHg, the heating temperature of the water bath is 50°C, and the extract is concentrated under reduced pressure When the solvent is completely dry, the concentrate is dissolved with 5mL water + 5mL absolute ethanol + 20mL glycerin to obtain e-cigarette liquid. The e-cigarette produced in the comparative example was used as the control sample, and the sensory evaluation was carried out. The result of the smoking evaluation was as follows: the test sample had obvious characteristics of Burley tobacco aroma and was strong. Compared with the comparative example, the smoke fragrance is more pure. The GC-MS picture of gained Burley tobacco extract figure 2 As shown, because the peak of nicotine is too large, in order to clearly show other components, t...

Embodiment 2

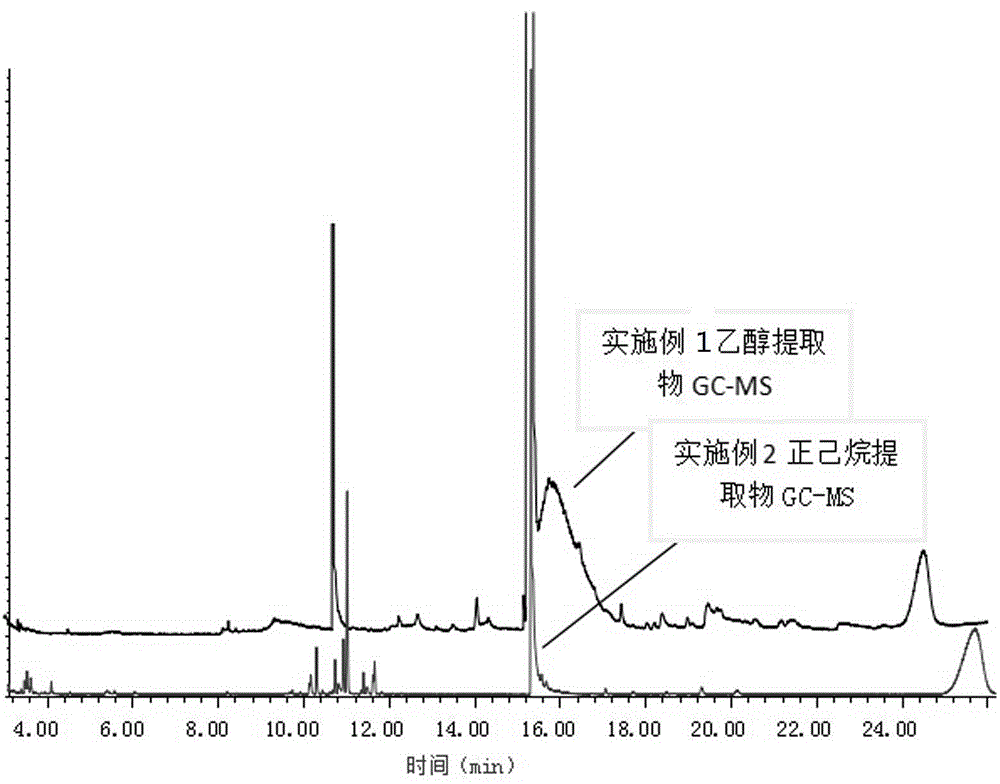

[0036] Soak 10g of American Burley tobacco S-B3F tobacco powder in 200mL of n-hexane for 4h, extract for 3h with the improved Soxhlet extraction device of the present invention, the vacuum degree is 80mmHg, the heating temperature of the water bath is 45°C, and the extract is concentrated under reduced pressure to The solvent was completely dried, and the concentrate was dissolved in 5mL water + 5mL absolute ethanol + 20mL glycerin to obtain e-cigarette liquid. Taking the e-cigarette liquid produced in Example 1 as a comparison, the sensory evaluation results are as follows: greater energy, stronger sense of satisfaction, and a little miscellaneous smell.

[0037] image 3 The GC-MS figure and figure 1 contrast. from image 3 It can be seen that ethanol is a polar solvent, while n-hexane is used as a non-polar solvent, and the aroma components extracted by the non-polar solvent n-hexane are densely distributed in the area with a short retention time, that is, the left end o...

Embodiment 3

[0039] Soak 10g of American Burley tobacco S-C3F powdered tobacco in 200mL of ethanol for 4h, extract with the improved Soxhlet extraction device of the present invention for 3h, the vacuum degree is 40mmHg, the heating temperature of the water bath is 50°C, and the extract is concentrated under reduced pressure until the solvent is completely dissolved. After drying, the concentrate was dissolved with 5mL water + 5mL absolute ethanol + 20mL glycerin to obtain electronic cigarette liquid. Make two samples, add 0.5ml of commercially available e-liquid to one as a control sample; add 0.5ml of the same commercially available e-liquid as the control sample to the other as an experimental sample, and add 0.25ml of the preparation prepared in this example Burley tobacco extract smoke liquid, comparative evaluation and evaluation results: Compared with the control sample, the Burley smoke smoke characteristics of the experimental sample are obvious, strong and satisfying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com