Method for preparing grafted bagasse xylan copolymer

The technology of xylan and copolymer is applied in the field of preparation of grafted bagasse xylan copolymer, and achieves the effects of good thermal stability and surface activity, high utilization rate of raw materials and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

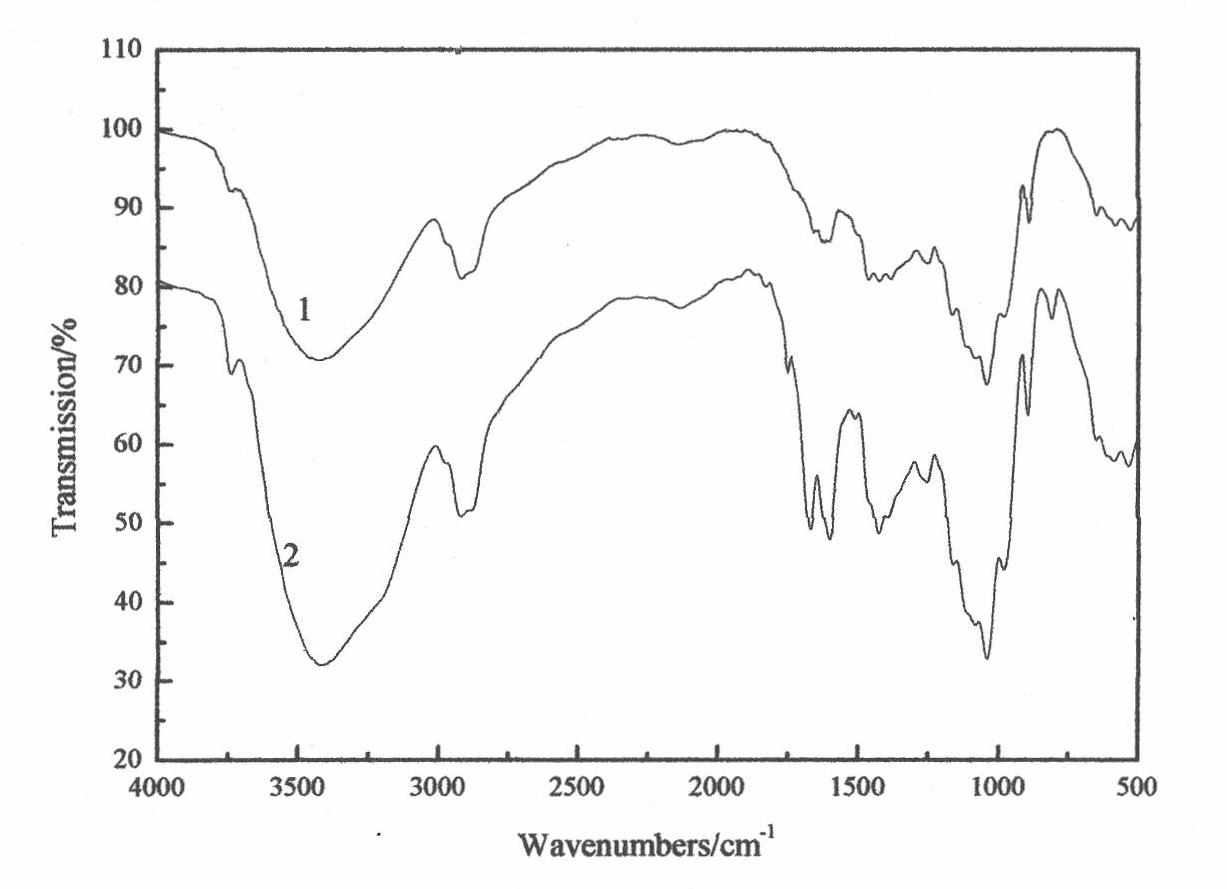

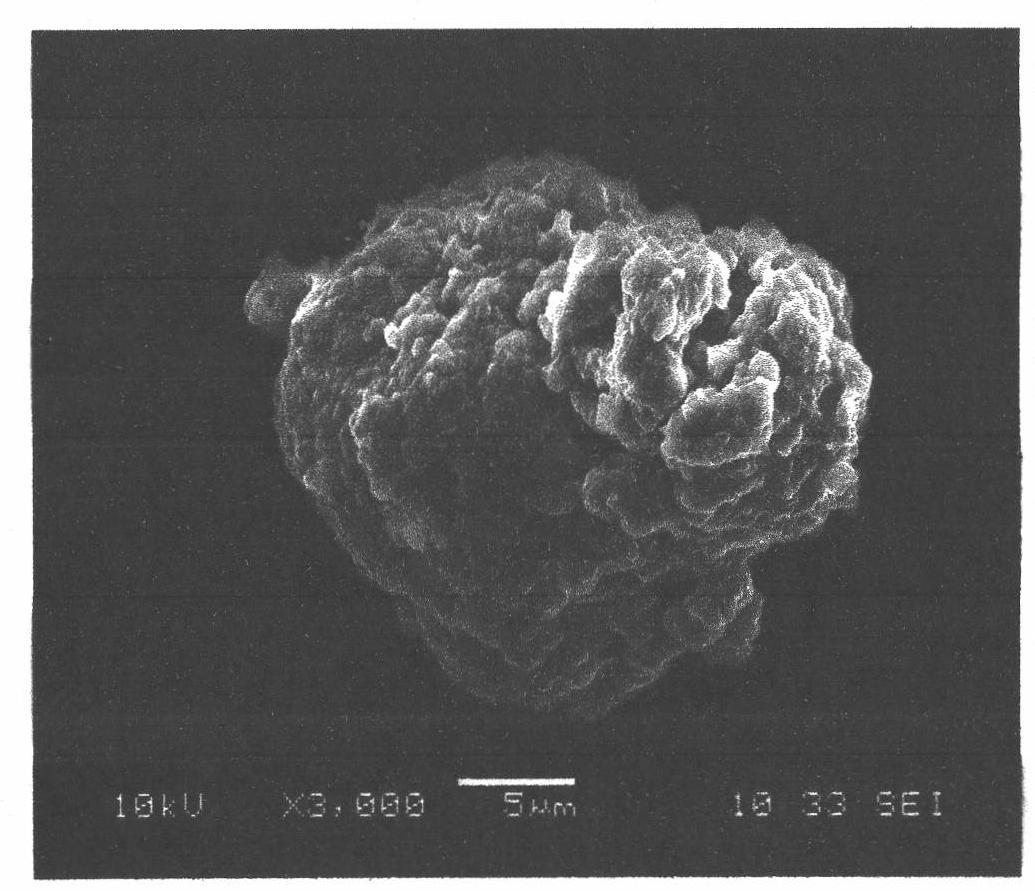

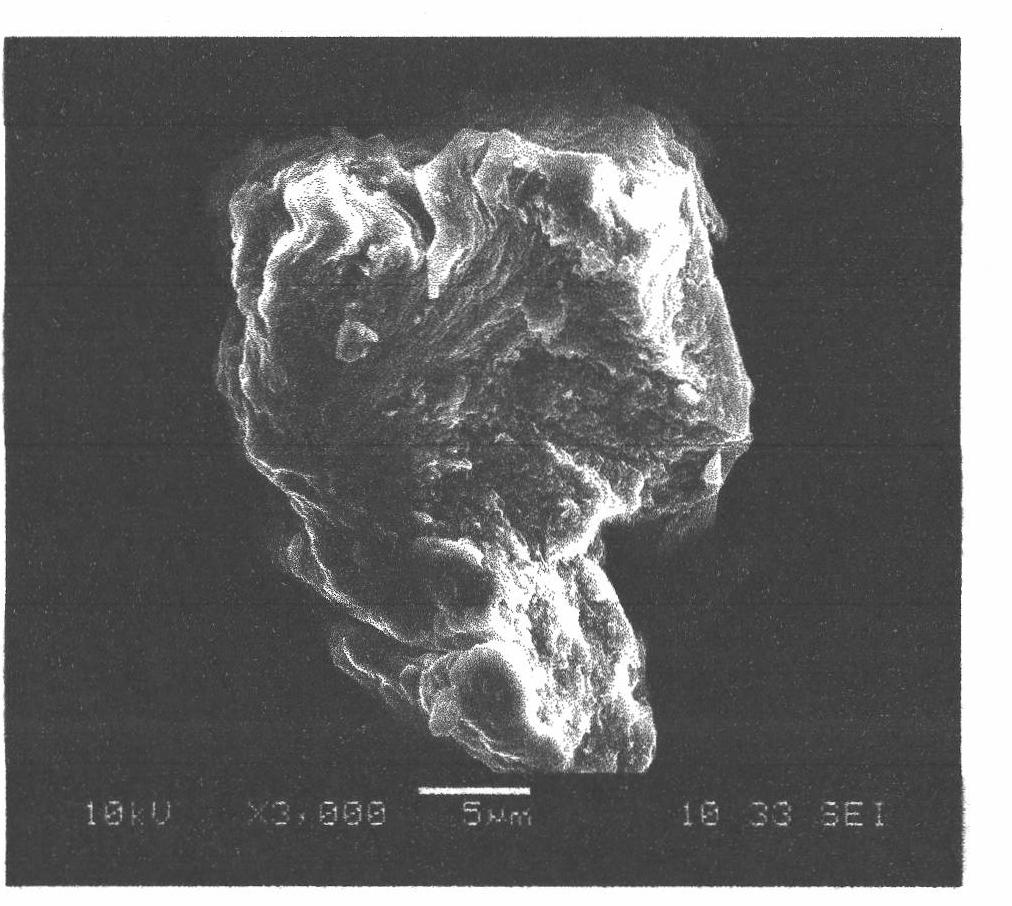

Image

Examples

Embodiment 1

[0025] 1. Take 10g of bagasse xylan and 30mL of solvent into the reactor for stirring, use 0.5mol / L hydrochloric acid to control the pH of the system to 8, and stir at room temperature for 0.5 hours;

[0026] 2. Add 0.5g of initiator potassium persulfate, then add 0.3g of composite crosslinking agent N,N-methylenebisacrylamide / divinylbenzene, dissolve 5g of acrylamide in 20mL of distilled water for later use;

[0027] 3. Put the above-mentioned acrylamide solution and 10.0mL butyl acrylate solution in a constant pressure dropping funnel, add dropwise to the reaction system, and react at 50°C for 8 hours;

[0028] 4. Suction filtration while hot to obtain primary crude product; the crude product was repeatedly washed 3 times with 90% ethanol water solution by volume, then placed in a vacuum drying oven, dried for 12 hours at 60°C, and then allowed to dry naturally in the furnace Cooling to get thick graft copolymer;

[0029] 5. Extract the crude graft copolymer with analytical...

Embodiment 2

[0031] 1. Take 12g of bagasse xylan and 50mL of solvent into the reactor for stirring, use 0.5mol / L hydrochloric acid to control the pH of the system to 9, and stir at room temperature for 0.5 hours;

[0032] 2. Add 0.6g of initiator potassium persulfate, then add 0.36g of composite crosslinking agent N,N-, methylenebisacrylamide / divinylbenzene, dissolve 6g of acrylamide in 20mL of distilled water for later use;

[0033] 3. Put the above-mentioned acrylamide solution and 24.0mL butyl acrylate solution in a constant pressure dropping funnel, add dropwise to the reaction system, and react at 70°C for 10 hours;

[0034] 4. Suction filtration while hot to obtain primary crude product; the crude product was repeatedly washed twice with 90% ethanol aqueous solution, placed in a vacuum drying oven, dried at 60°C for 12 hours, and then allowed to dry naturally in the furnace Cooling to get thick graft copolymer;

[0035] 5. Extract the crude graft copolymer with analytically pure ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com