Method for recovering lac and extracting lac wax

A kind of shellac wax and shellac technology, applied in the field of shellac wax, can solve problems such as wasting shellac resources, environmental pollution, etc., and achieve the effects of solving secondary pollution and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020]Example 1: 18000mL of sodium carbonate solution with a concentration of 0.2% (wt%) was heated to a temperature of 85°C, and 2000g (moisture content 41.5wt%) of purple shellac slag was added for dissolution. After the addition, the mixture was stirred at a constant temperature and reacted for 30min. After the stirring is stopped, at a temperature of 85°C, filter with a stainless steel screen with a pore size of 0.074mm, separate branches, insect corpses and insoluble shellac shells, and obtain a sodium carbonate solution containing shellac and shellac wax that removes mechanical impurities; filter After the solution obtained is placed in a cold water bath and cooled to a temperature of 35°C, add 150 mL of sodium hypochlorite solution with an available chlorine content wt% of 4% under stirring and bleach until the color index is lower than 1.0, then stop, and the bleaching time is 10 hours; after standing still and naturally cooling , take out the floating matter solidified...

Embodiment 2

[0023] Example 2: 12000mL of sodium carbonate solution with a concentration of 0.5% (wt%) was heated to a temperature of 90°C, and 2000g (moisture content 41.5wt%) of purple shellac slag was added for dissolution. After the addition, the mixture was stirred at a constant temperature and reacted for 60min. After stopping the stirring, at a temperature of 90°C, filter through a stainless steel screen with a pore size of 0.074 mm, separate branches, insect corpses and insoluble shellac shells, and obtain a sodium carbonate solution containing shellac and shellac wax that removes mechanical impurities; filter After the solution obtained is placed in a cold water bath and cooled to a temperature of 40°C, under stirring, 140 mL of sodium hypochlorite solution with an available chlorine content of 3% by weight is added to bleach until the color index is lower than 1.0 and then stop. The bleaching time is 21 hours; after standing still and naturally cooling , take out the floating matt...

Embodiment 3

[0026] Example 3: Warm up 18000mL of water to 90°C, add 2000g of purple-red shellac slag (moisture 41.5wt%) to dissolve, and react for 180min under constant temperature stirring after the addition. After stopping the stirring, at a temperature of 90°C, filter through a stainless steel screen with a pore size of 0.074 mm, separate branches, insect corpses and insoluble shellac shells, and obtain a sodium carbonate solution containing shellac and shellac wax that removes mechanical impurities; filter After the solution obtained is placed in a cold water bath and cooled to a temperature of 28°C, under stirring, add 1480mL of sodium hypochlorite solution with an available chlorine content of 4% by weight to bleach until the color index is lower than 1.0 and then stop. The bleaching time is 18h; after standing still and naturally cooling , take out the floating thing solidified on the surface to obtain shellac wax crude product, shellac wax crude product weight 325.9g; Remaining sol...

PUM

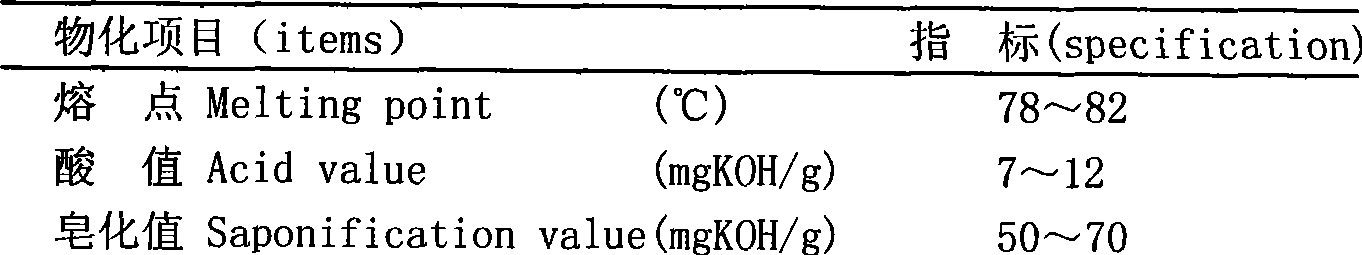

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Saponification value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com