Preparation method and application for chitosan-grafted quadri(p-carboxylphenyl) metalloporphyrin

A carboxyphenyl, metalloporphyrin technology, applied in the field of catalyst preparation, can solve the problems of long reaction time, large pollution, low metalloporphyrin reuse rate and the like, and achieves simple preparation, low cost, and improved reuse efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

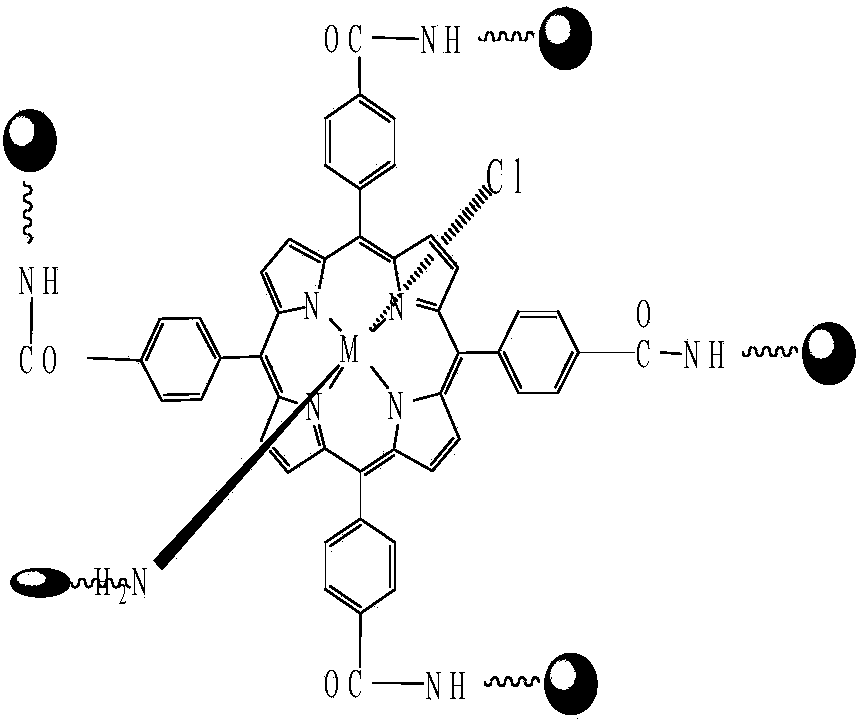

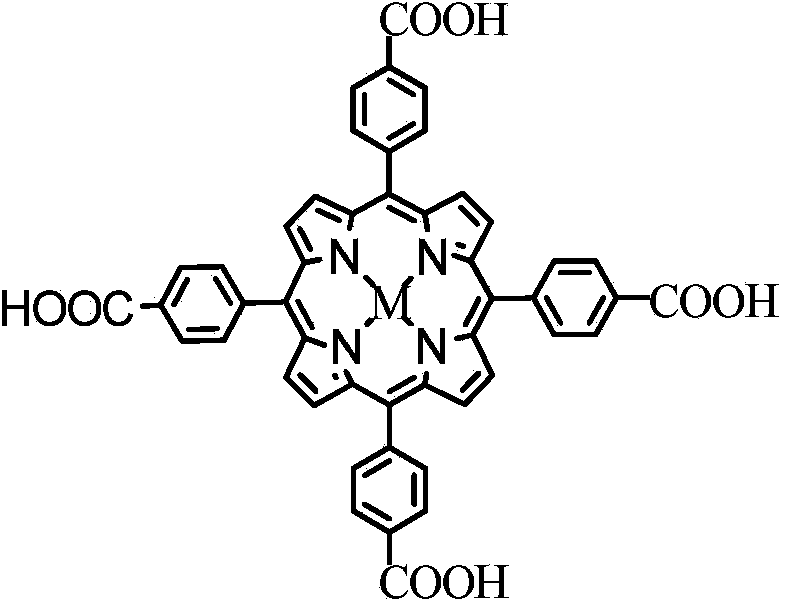

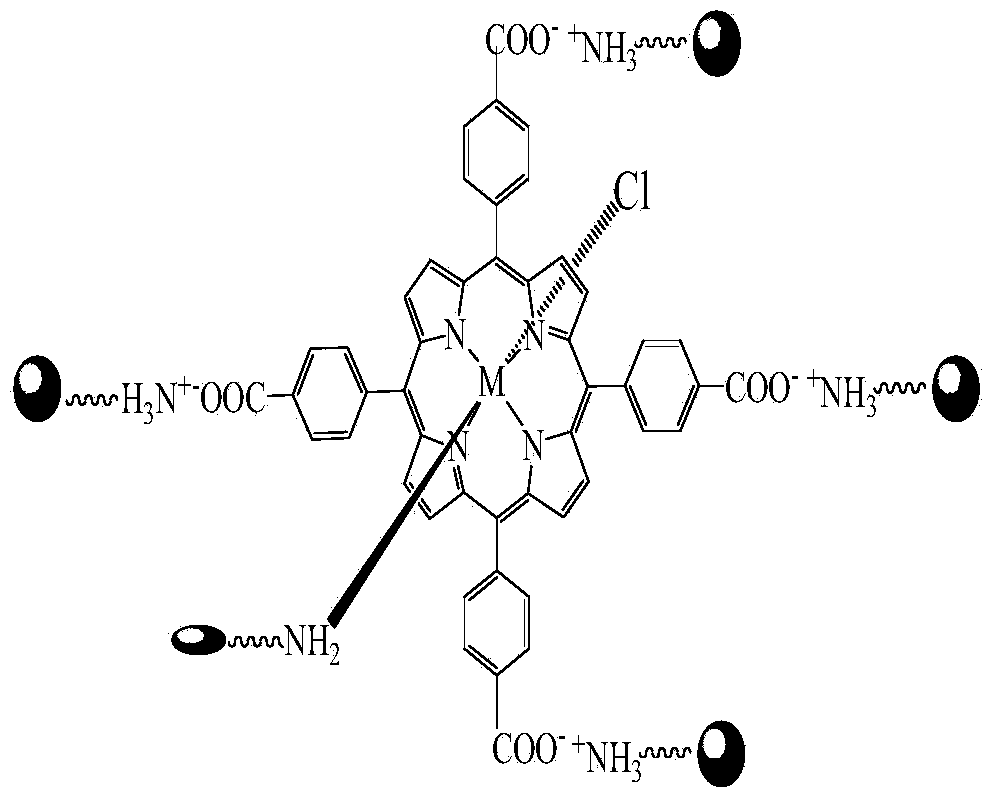

[0029] 1. Preparation of chitosan-grafted tetrakis(p-carboxyphenyl)cobalt porphyrin

[0030] Weigh 0.0209 parts of Co TCPP Cl and add 133.6 parts of dichloromethane and 0.948 parts of N,N-dimethylformamide into a three-neck flask, blow dry nitrogen, heat and stir, add 0.82 parts of thionyl chloride, and heat to reflux for 2 hours . Then add 10 parts of chitosan powder and 200.4 parts of dichloromethane, stir and reflux, react for 3 hours, and stop heating. Filter with suction and wash the filter cake with dichloromethane. The filter cake was then washed with dichloromethane using a Soxhlet extractor to remove unamidated metalloporphyrins. The product was vacuum-dried at 65°C and 0.007MPa for 7 hours to prepare chitosan-grafted tetrakis(p-carboxyphenyl)cobalt porphyrin.

[0031] 2. Application of chitosan grafted tetrakis (p-carboxyphenyl) cobalt porphyrin

[0032] (1) chitosan grafted tetrakis (p-carboxyphenyl) cobalt porphyrin equivalent of 1.0mg tetrakis (p-carboxyphenyl...

Embodiment 2

[0044] Reuse of chitosan grafted tetra(p-carboxyphenyl)cobalt porphyrin

[0045] Chitosan grafted tetrakis (p-carboxyphenyl) cobalt porphyrin equivalent of 0.3 mg tetrakis (p-carboxyphenyl) cobalt porphyrin is put into a 250ml reactor, 200ml ethylbenzene is added, and the reaction temperature is 140 ℃, air pressure 0.8MPa, stirring speed 250 rpm, reaction time 4h, air flow 0.03m 3 / h, the conversion rate of ethylbenzene is 15.81%, the selectivity of alcohol and ketone is 83.23%, and the catalyst conversion number is 6.10×10 5 , The yield of alcohol and ketone is 13.15%. After stopping the catalytic reaction each time, after waiting for the natural sedimentation and separation of the catalytic material and the reaction mixture, filter it, wash it with ethanol, then dry it naturally, reclaim the catalytic material, and then use it to catalyze the air oxidation of ethylbenzene under the same reaction conditions. The repeated utilization of benzene can reach 4 times, and the con...

Embodiment 3

[0047] 1. Preparation of chitosan-grafted tetrakis(p-carboxyphenyl)manganese porphyrin

[0048] Weigh 0.0313 parts of Mn TCPP Cl, add to a three-necked flask containing 133.6 parts of dichloromethane and 1.422 parts of N,N-dimethylformamide, blow in dry nitrogen, stir and heat. Then add 1.23 parts of thionyl chloride and react for 3 hours. Add 200.4 parts of dichloromethane, and then add 15 parts of chitosan powder. After reflux for 3h, filter and wash the filter cake with dichloromethane. Then the filter cake is reflux washed with dichloromethane in a Soxhlet extractor, and the grafted product is then vacuum-dried at a temperature of 56° C., a vacuum degree of 0.010 MPa, and a time of 7 hours to obtain chitosan grafted tetra(p-carboxy phenyl) manganese porphyrin.

[0049] 2. Application of chitosan grafted tetrakis(p-carboxyphenyl)manganese porphyrin

[0050] (1) Chitosan grafted tetrakis (p-carboxyphenyl) manganese porphyrin equivalent of 1.0mg tetrakis (p-carboxyphenyl)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com