Chitosan tetrakis (p-sulfophenyl) metalloporphyrin and preparation method and application

A technology of sulfophenyl phenyl and metalloporphyrin, which is applied in the field of chemical engineering, can solve the problems of long reaction time, large pollution, low reuse rate of metalloporphyrin, etc., and achieves simple preparation, low cost, and improved reuse efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

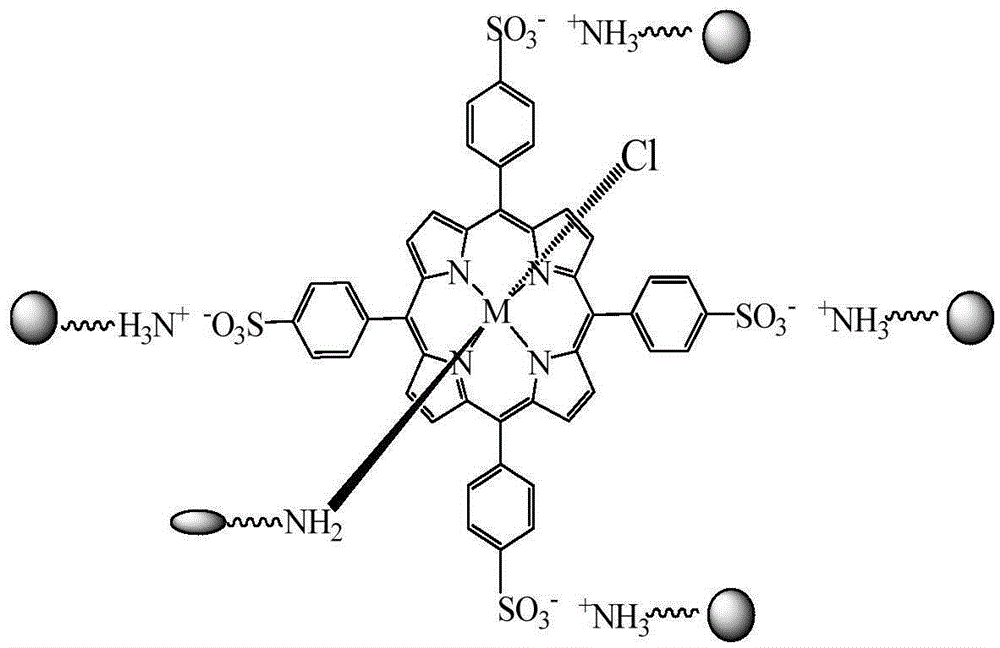

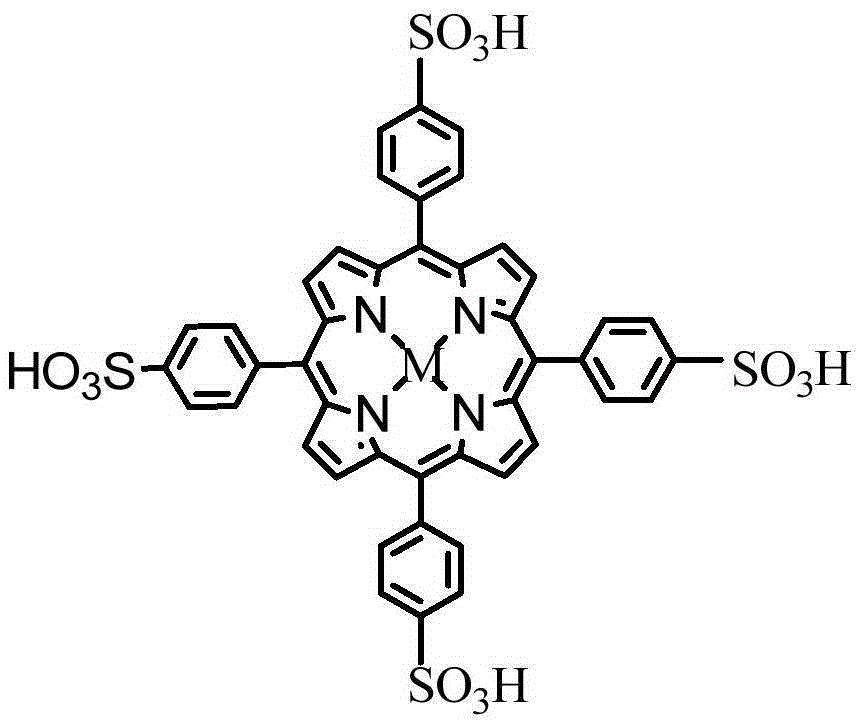

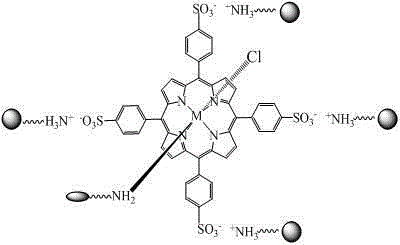

[0031] 1. Preparation of chitosan tetrakis (p-sulfophenyl) cobalt porphyrin

[0032] Add 30 parts of chitosan and 300 parts of distilled water in the reaction vessel, mechanically stir at high speed for 1 hour at room temperature until uniformly dispersed, slowly add 100ml of 0.3g / L tetrakis (p-sulfonic acid phenyl) cobalt porphyrin through the dropping funnel After stirring for 24 hours, filter with suction, and wash the filter cake with distilled water. The filter cake was then washed in a Soxhlet extractor to remove unreacted metalloporphyrins. Finally, the product was vacuum-dried for 6 hours at a controlled temperature of 60° C. and 0.007 MPa to obtain chitosan tetrakis(p-sulfophenyl)cobalt porphyrin.

[0033] 2. Application of chitosan tetrakis(p-sulfophenyl)cobalt porphyrin

[0034] (1) Chitosan tetrakis (p-sulfophenyl) cobalt porphyrin loaded with 1.0 mg tetrakis (p-sulfophenyl) cobalt porphyrin was put into a 500ml reactor, and 173.2g ethylbenzene was added , oxyge...

Embodiment 2

[0045] Reuse of chitosan tetrakis(p-sulfophenyl)cobalt porphyrin

[0046] Chitosan tetrakis (p-sulfonate phenyl) cobalt porphyrin loaded with 1mg tetrakis (p-sulfonate phenyl) cobalt porphyrin is put into 500ml reactor, adds 173.2g ethylbenzene, reaction temperature 140 ℃, oxygen pressure 0.8MPa, stirring speed 200 rpm, reaction time 4h, oxygen flow rate 0.03m 3 / h. At 3.0h, the conversion rate of ethylbenzene was 17.78%, the selectivity of alcohol and ketone was 71.46%, the yield of alcohol and ketone was 12.71%, and the catalyst conversion number was 2.20×10 5 ; At 3.5h, the conversion rate of ethylbenzene was 20.67%, the selectivity of alcohol and ketone was 75.80%, the yield of alcohol and ketone was 15.67%, and the conversion number of catalyst was 2.54×10 5 ; At 4.0h, the conversion rate of ethylbenzene was 26.92%, the selectivity of alcohol and ketone was 74.01%, the yield of alcohol and ketone was 19.92%, and the conversion number of catalyst was 3.36×10 5 . After ...

Embodiment 3

[0055] 1. Preparation of chitosan tetrakis(p-sulfophenyl)manganese porphyrin

[0056] Add 35 parts of chitosan and 300 parts of distilled water that have been weighed in the reaction vessel, mechanically stir at high speed for 1.5h at room temperature, until uniform, slowly add 100ml0.35g / L tetrakis (p-sulfonic acid benzene) through the dropping funnel Base) manganese porphyrin aqueous solution, after stirring for 30h, suction filtration, wash the filter cake with distilled water. The filter cake was then washed in a Soxhlet extractor to remove unreacted metalloporphyrins. Finally, the product was vacuum-dried for 7 hours at a controlled temperature of 65° C. and 0.007 MPa to obtain chitosan tetrakis(p-sulfophenyl)manganese porphyrin.

[0057] 2. Application of chitosan tetrakis(p-sulfophenyl)manganese porphyrin

[0058](1) Put chitosan tetrakis(p-sulfophenyl)manganese porphyrin loaded with 1.0mg tetrakis(p-sulfophenyl)manganese porphyrin into a 500ml reactor, add 173.2g eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com