Acrylonitrile swollen yarn for carbon fiber, precursor fiber bundle, flame-proof fiber bundle, carbon fiber bundle, and production methods thereof

一种前驱体纤维、制造方法的技术,应用在纤维化学特征、纤维处理、湿纺法等方向,能够解决复杂工序、效果不充分、难以实用化等问题,达到高机械特性、机械性能优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1~3

[0175] [Preparation of swollen silk and precursor fiber]

[0176] Acrylonitrile and methacrylic acid were polymerized by aqueous suspension polymerization to obtain an acrylonitrile-based copolymer composed of acrylonitrile unit / methacrylic acid unit=98 / 2% by mass. The obtained polymer was dissolved in dimethylformamide to prepare a spinning dope having a concentration of 23.5% by mass.

[0177] The spinning dope is temporarily spun out into the air from a spinneret equipped with discharge holes with a diameter of 0.13 mm and a number of 2000 holes, and then it is passed through a space of about 4 mm, and then discharged into a room temperature-controlled to about 15° C. It was coagulated in a coagulation solution containing an aqueous solution of 79.5% by mass of dimethylformamide, and the coagulated filaments were drawn. Next, after stretching by 1.1 to 1.3 times in air, it stretches by 1.1 to 2.9 times in a stretching tank filled with an aqueous solution containing 30% by ...

Embodiment 2~16 and comparative example 4~9

[0199] A swollen yarn and a precursor fiber bundle were obtained in the same manner as in Example 1, except that some conditions of the spinning process were changed. The fineness of the precursor fiber was 0.77 dtex, and the ratio of the major axis to the minor axis (major axis / short axis) of the fiber cross section of the single fiber was 1.005. Next, carbon fiber bundles were produced under the same firing conditions. The ratio of the long diameter to the short diameter (long diameter / short diameter) of the fiber cross-section of the single fiber of the carbon fiber bundle was 1.005, and the diameter was 4.9 μm.

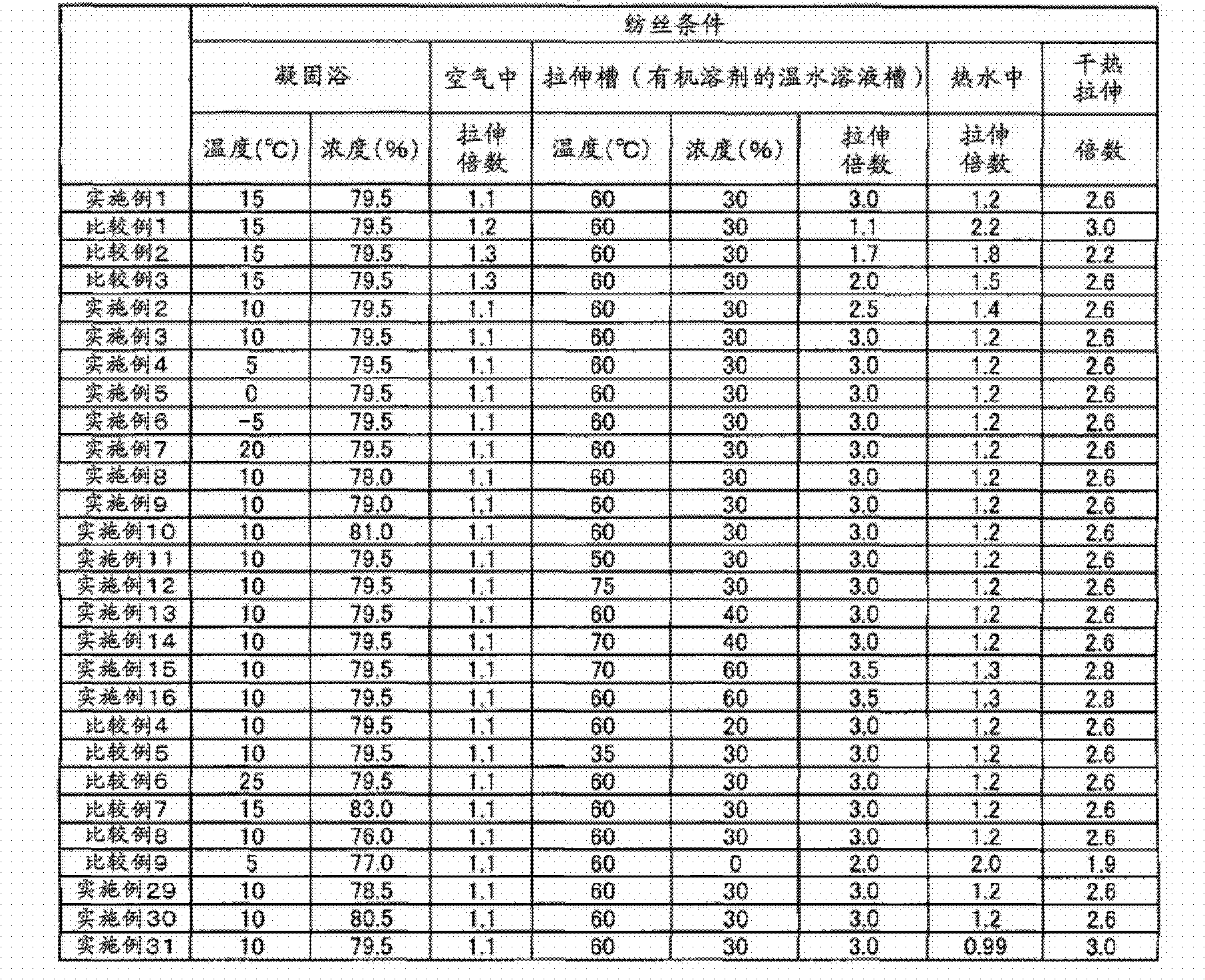

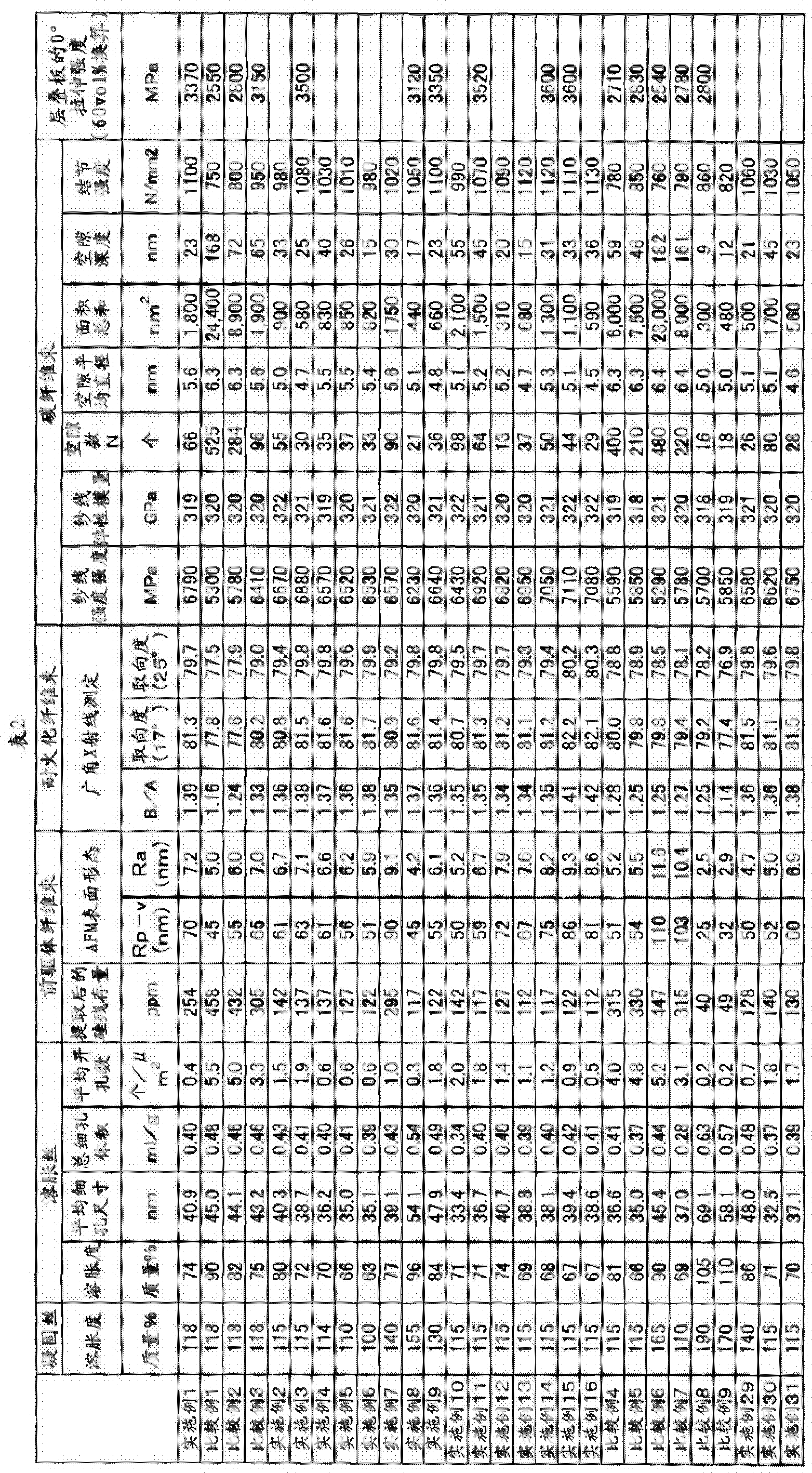

[0200] Table 1 summarizes the conditions of the spinning process, and Table 2 summarizes the evaluation results of various fiber bundles.

Embodiment 17~20

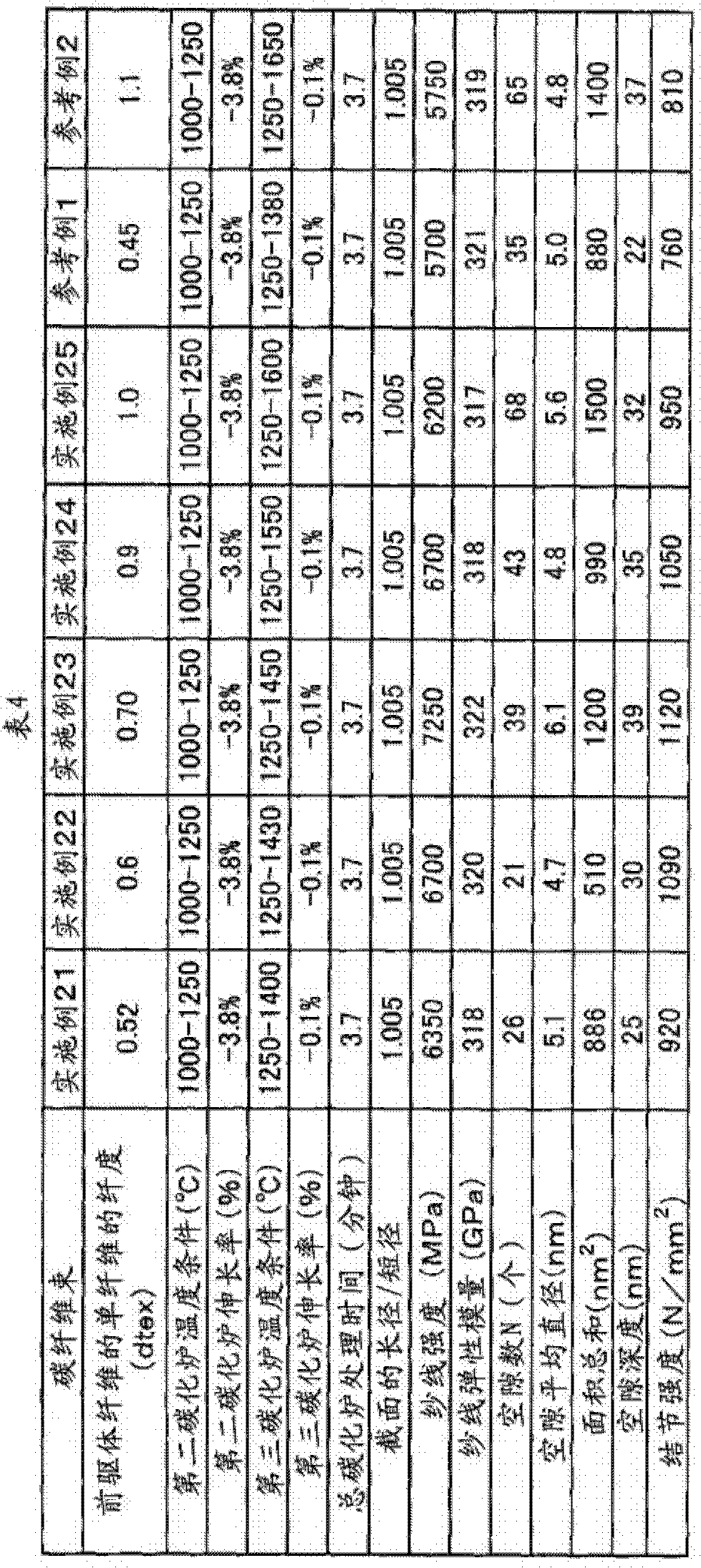

[0202] Using the precursor fiber bundle obtained in Example 14, only the heat treatment conditions were changed in the second and third carbonization furnaces, and other conditions were the same as in Example 14 to produce a carbon fiber bundle. Table 3 shows the heat treatment conditions and properties of the carbon fiber bundles.

[0203] table 3

[0204] carbon fiber bundle

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com