Method for preparing in-situ passivation restoring material of soil heavy metal with copolycondensation method

A technology for repairing materials and heavy metals, applied in chemical instruments and methods, restoration of polluted soil, water pollutants, etc., can solve the problem of lack of stability of passivation material repair effect and insufficient understanding of environmental safety, compound pollution treatment of multiple elements The effect is not outstanding, affecting the physical and chemical properties of the soil, etc., to achieve the effect of no secondary pollution, little impact on the physical and chemical properties of the soil and fertility, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Preparation of soil heavy metal in-situ passivation repair material

[0021] 1) Measure 490g of deionized water and put it in a 2000ml beaker, add 210g of methanol and stir it electrically;

[0022] 2) Add template agent cetyltrimethylammonium bromide (CTAB) 15.31g and sodium hydroxide (NaOH) 3.84g under vigorous stirring conditions, and stir until they are completely dissolved; 3) Tetramethoxysilane ( TMOS) 38.05g and mercaptopropyltrimethoxysilane (MPTMS) 19.63g as the silicon source, transfer to a 100ml beaker and mix the two; 4) Mix the well-mixed tetramethoxysilane (TMOS) and mercaptopropyl Add trimethoxysilane (MPTMS) to the above solution and continue to stir for 12 hours; 5) After stopping the stirring, transfer the above solution to a constant temperature water bath at 96°C and heat for 12 hours; 6) Then transfer the reaction system to a Buchner funnel for suction filtration , collect the filter cake and dry to obtain the white powder primary produc...

Embodiment 2

[0024] Example 2: Application of passivation repair materials in water body lead and cadmium pollution control

[0025] Configure a series of different Pb 2+ 、Cd 2+ As a typical working solution of heavy metal polluted water, measure 50ml and place them in 100ml centrifuge tubes, weigh 0.05g of passivation repair agent and add them to the centrifuge tubes that have been added with heavy metal pollution working solution respectively. Passivation materials and sewage Ratio 1g / L, shake at constant temperature for 12h, take the supernatant after high-speed centrifugation, use atomic absorption spectrophotometer to measure the concentration of heavy metal ions in the solution, and calculate the heavy metal loading and Saturated load.

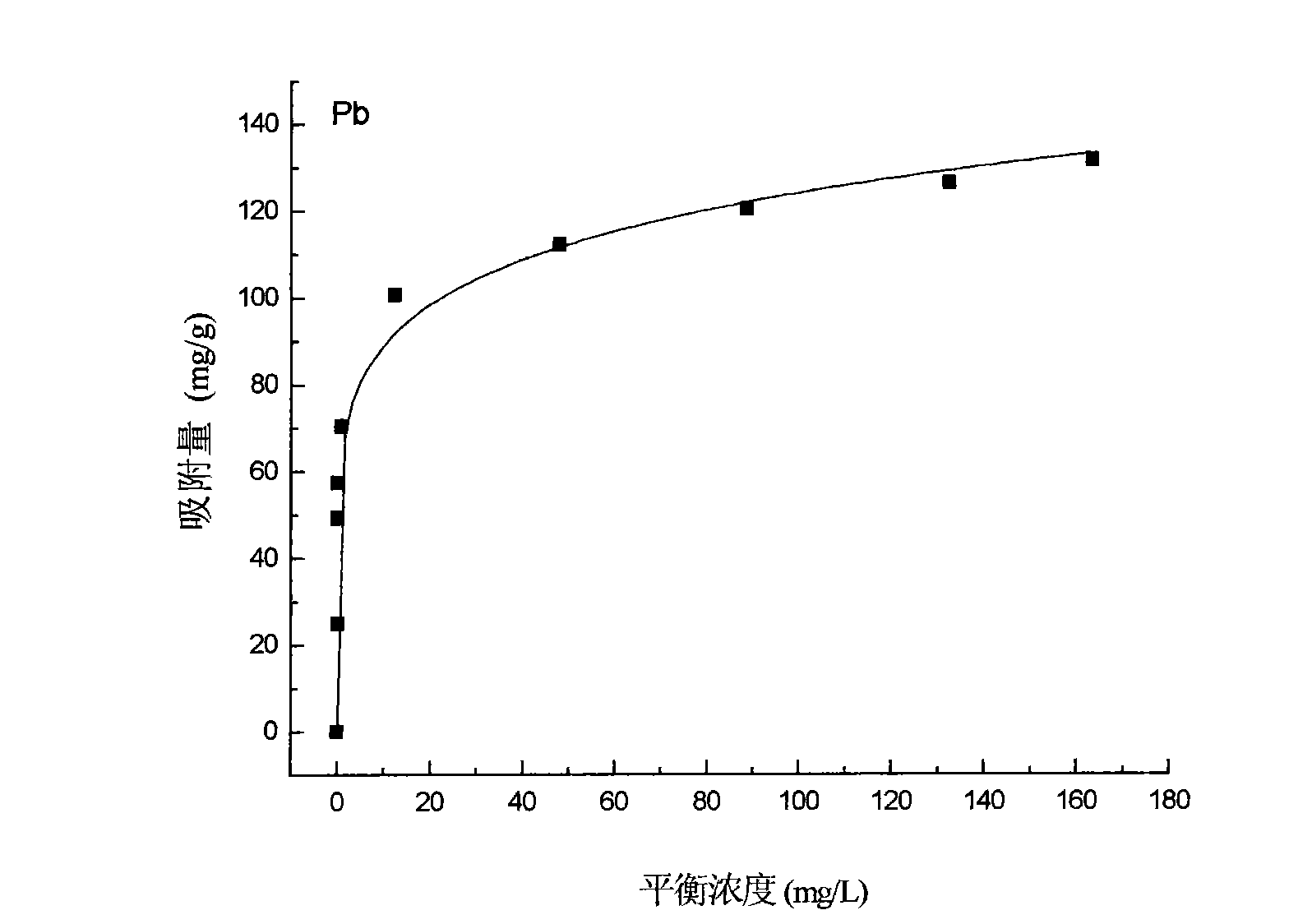

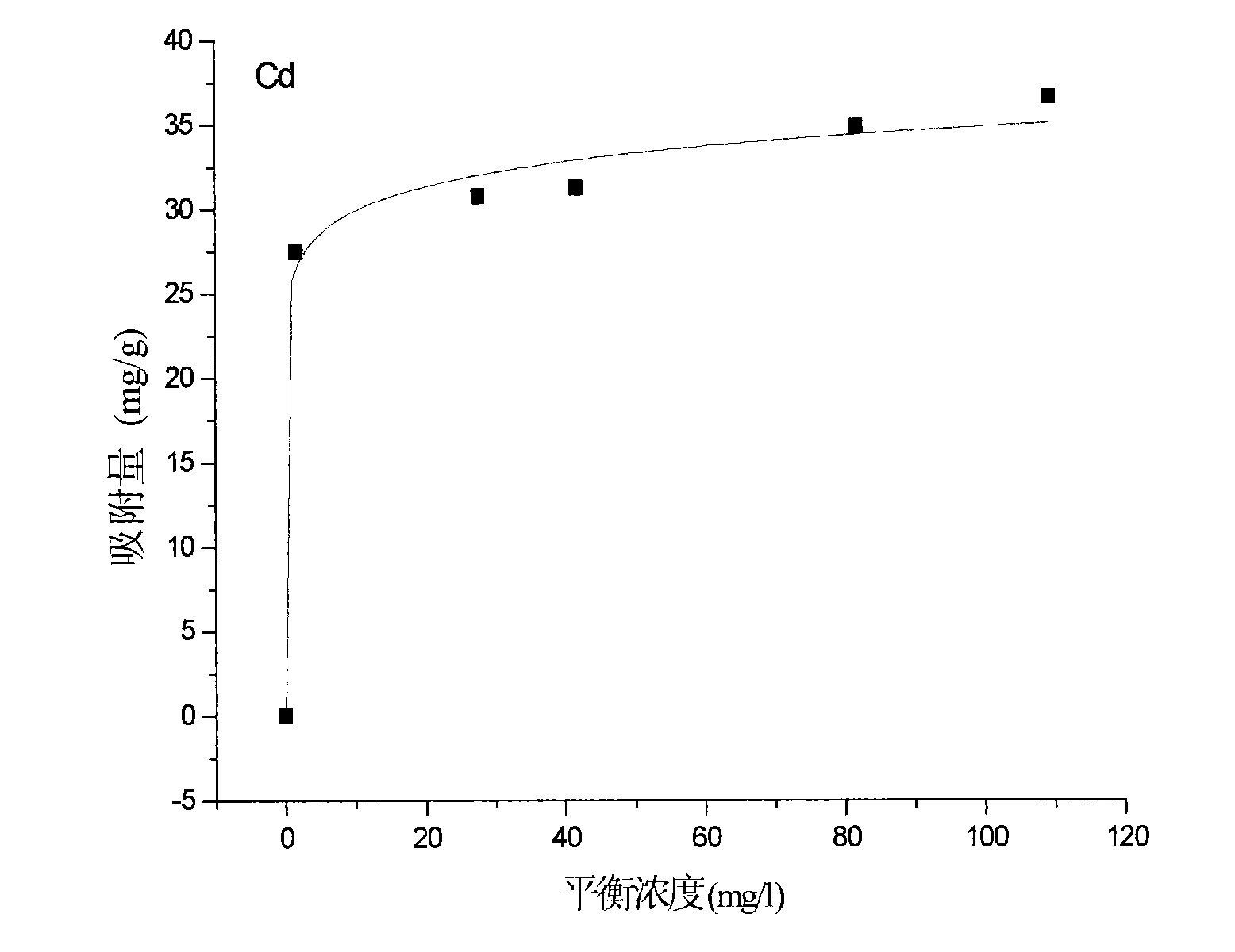

[0026]The results show that the passivation repair material has a good repair effect on lead and cadmium heavy metal pollution in the water body, and the results are as follows: Figure 1a and Figure 1b As shown, its adsorption isotherm conforms ...

Embodiment 3

[0027] Example 3: Kinetic detection of lead and cadmium pollution repaired by passivation repair materials

[0028] Prepare the concentration of 200mg / l Pb respectively 2+ solution and 100mg / l Cd 2+ Transfer 500ml of the solution to a 1000ml beaker, set the ratio of passivation material to dirty liquid to 1g / L, add 0.5g of passivation restoration agent accurately weighed under the condition of vigorous stirring, and start the timing, and take samples at different times after filter membrane filtration Measure the concentration of heavy metal ions, calculate the load of heavy metals, and calculate the relationship between time and load.

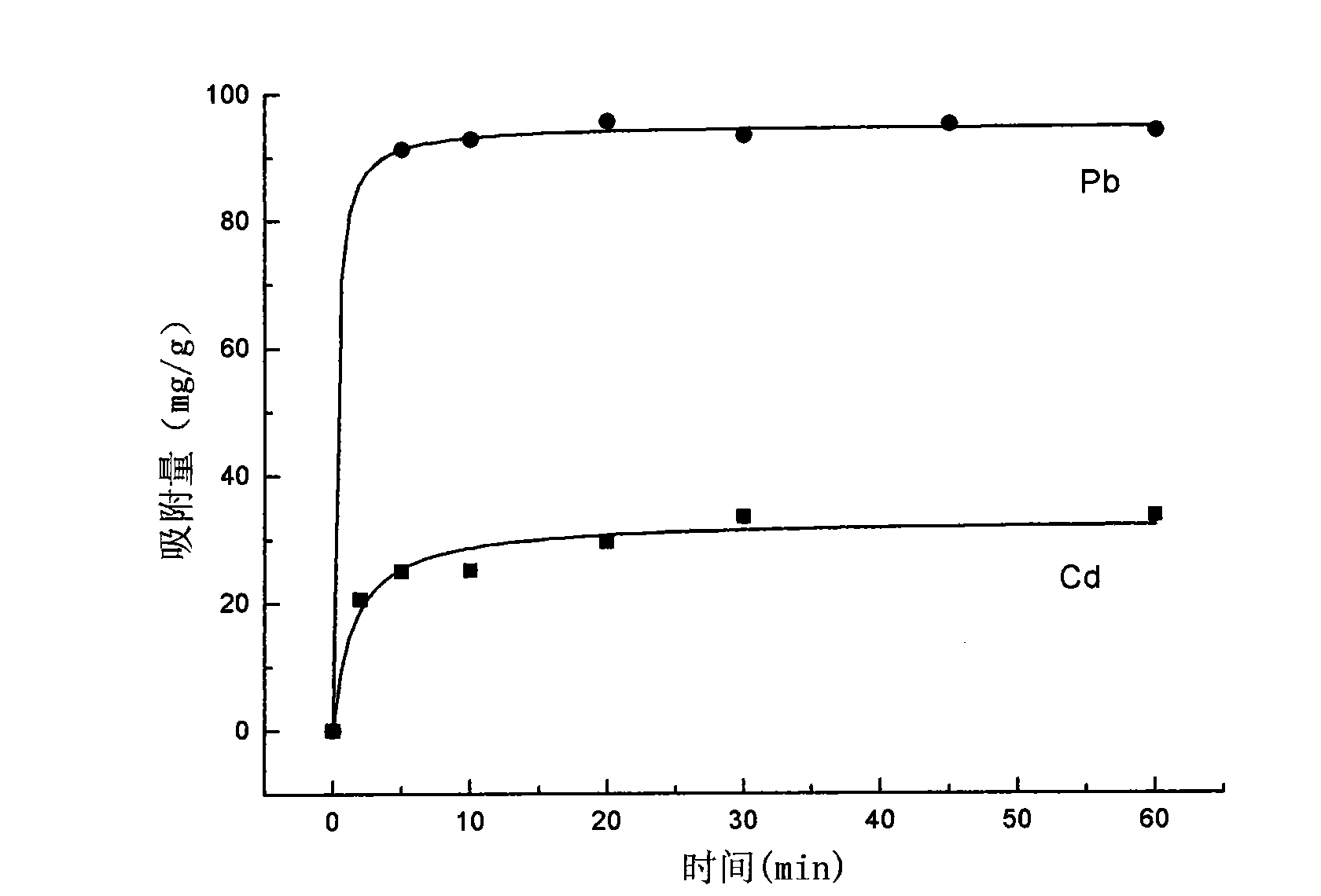

[0029] Such as figure 2 As shown, the results show that the passivation repair material reacts rapidly with heavy metal ions in the solution, reaching equilibrium within 20 minutes, and the response time is extremely short.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com