Pore-diameter extension method for UiO-66 metal organic framework material and application

A metal organic framework, uio-66 technology, applied in the field of porous materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

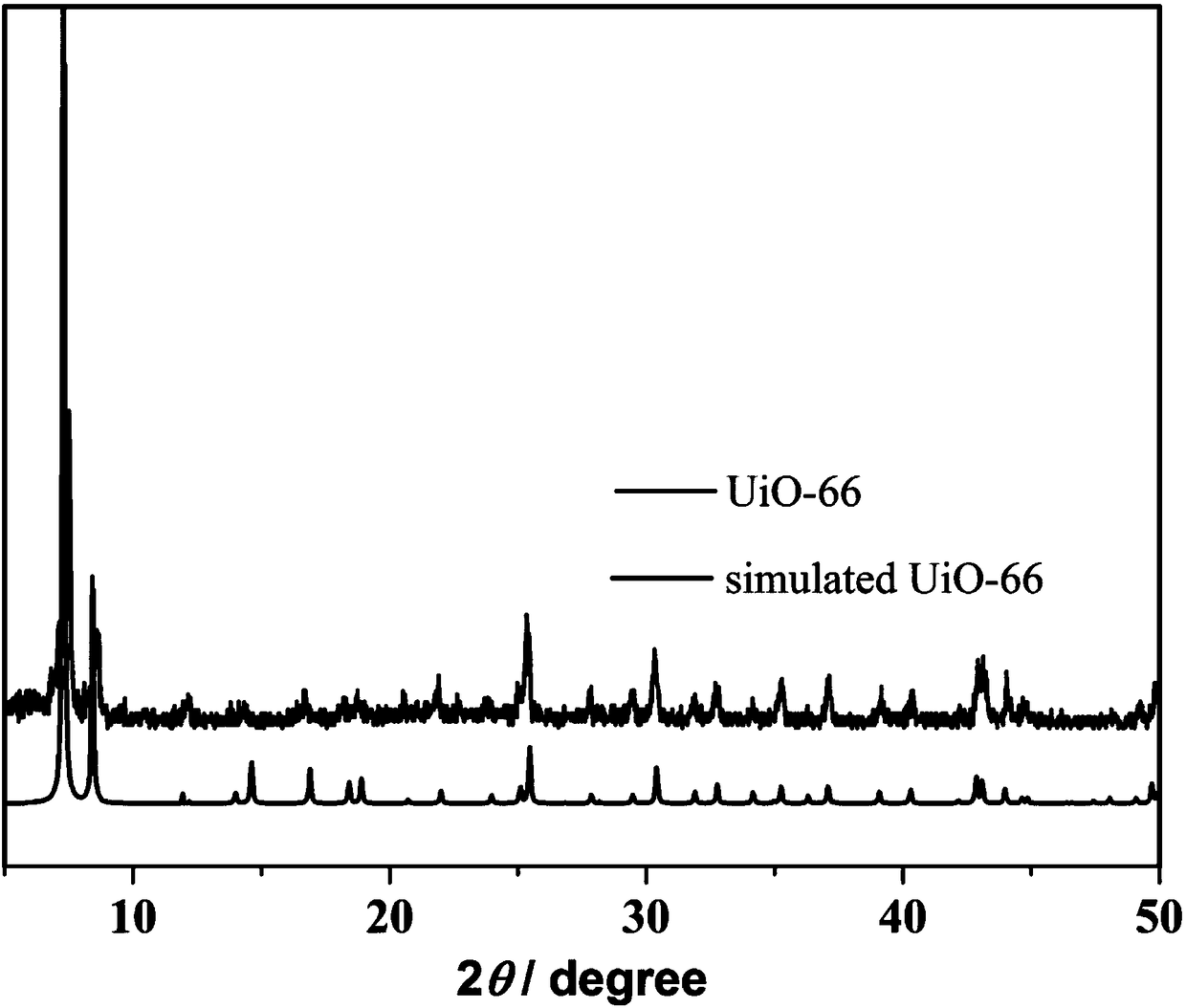

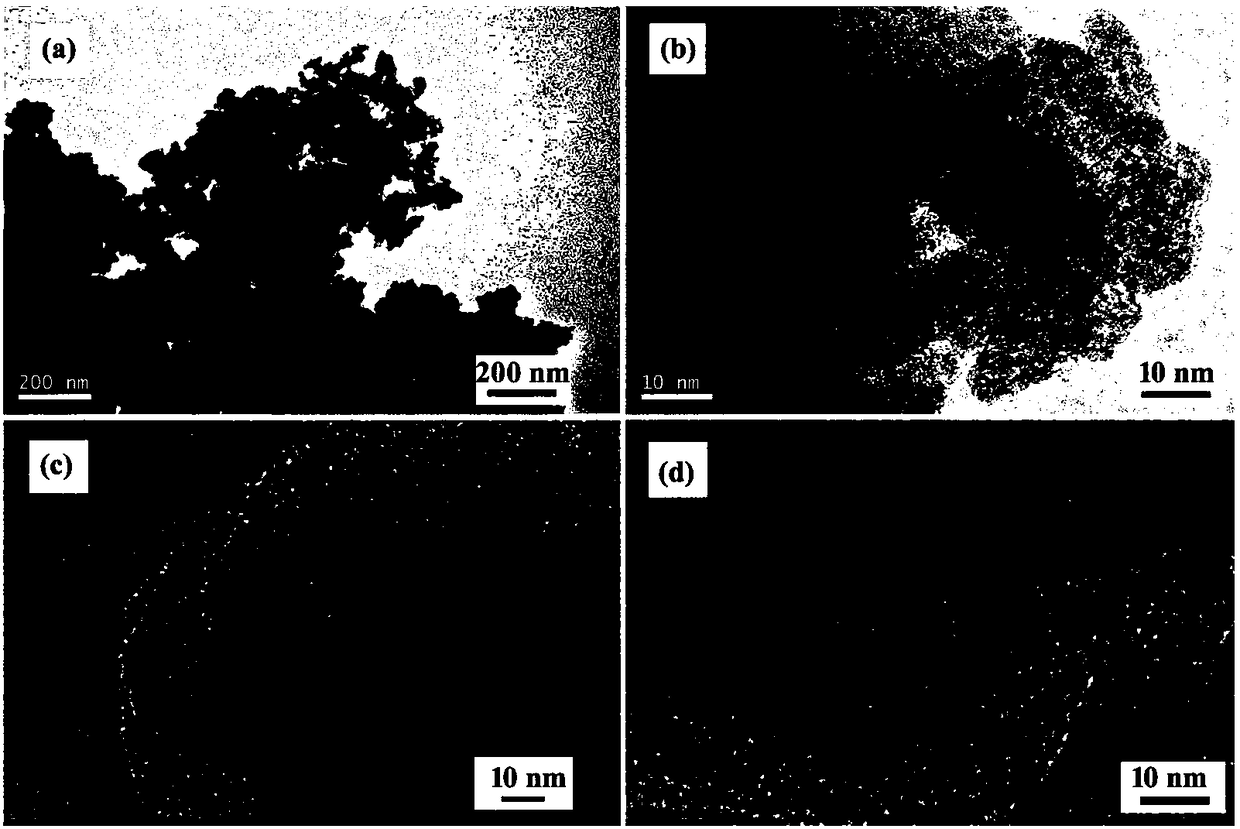

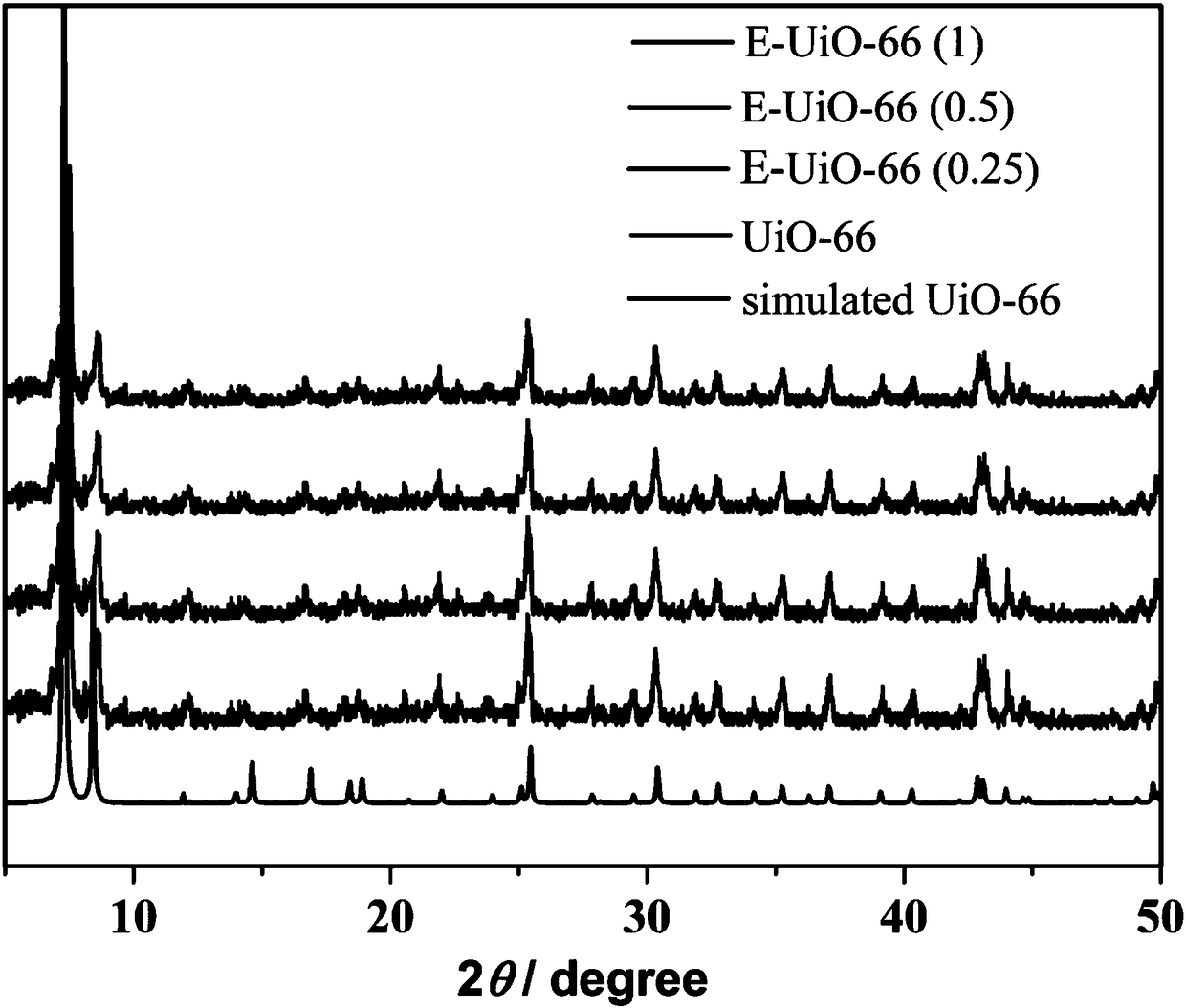

[0029] The pore diameter expansion method of UiO-66 metal organic framework material, comprises the following steps:

[0030] (1) Get 2.47 parts by weight of zirconium tetrachloride powder, 1.47 parts by weight of terephthalic acid powder, and 1 part by weight of formic acid, mix them and place them in a single-port container filled with 95 parts by weight of N,N-dimethylformamide In the flask, sonicate for 10 minutes to fully dissolve;

[0031] (2) A condensing reflux device is installed on the single-necked flask, and it is placed in a microwave oven, and the microwave treatment is 15min, and the microwave power is 500W, and the first mixture is obtained and centrifuged to obtain the first solid product, and the rotating speed of centrifugation is 8000r / min, centrifugation time is 3min;

[0032] (3) Wash the first solid product with N,N-dimethylformamide and ethanol as the washing liquid. The washing method is to mix the washing liquid and the first solid product in a test...

Embodiment 2

[0037] The pore diameter expansion method of UiO-66 metal organic framework material, comprises the following steps:

[0038] (1) Take 2.47 parts by weight of zirconium tetrachloride powder and 1.47 parts by weight of terephthalic acid powder, mix them and place them in a single-necked flask filled with 95 parts by weight of N,N-dimethylformamide, and ultrasonically treat them for 10 minutes , to make it fully dissolved;

[0039] (2) A condensing reflux device is installed on the single-necked flask, and it is placed in a microwave oven. The microwave reaction is 15min, and the microwave power is 500W to obtain the first mixture and centrifuge to obtain the first solid product. The rotating speed of the centrifuge is 8000r / min, centrifugation time is 3min;

[0040] (3) Wash the first solid product with N,N-dimethylformamide and ethanol as the washing liquid. The washing method is to mix the washing liquid and the first solid product in a test tube and then place them in a ce...

Embodiment 3

[0045] The pore diameter expansion method of UiO-66 metal organic framework material, comprises the following steps:

[0046] (1) Take 2.47 parts by weight of zirconium tetrachloride powder and 1.47 parts by weight of terephthalic acid powder, mix them and place them in a single-necked flask filled with 95 parts by weight of N,N-dimethylformamide, and ultrasonically treat them for 10 minutes , to make it fully dissolved;

[0047] (2) Install a condensing reflux device on the single-necked flask, place it in a microwave oven, microwave for 15 minutes, and the microwave power is 500W to obtain the first mixture and separate it by suction to obtain the first solid product. The rotating speed of centrifugation is 8000r / min, the centrifugation time is 3min;

[0048] (3) Wash the first solid product with N,N-dimethylformamide and ethanol as the washing liquid. The washing method is to mix the washing liquid and the first solid product in a test tube and then place them in a centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com