Preparation method of mercury ion adsorption resin

A technology for adsorbing resin and mercury ions, which is applied in chemical instruments and methods, adsorbed water/sewage treatment, alkali metal oxides/hydroxides, etc., and can solve the problems of high preparation cost, difficult sediment treatment, and complex preparation process. , to achieve the effect of strong resistance to organic pollution, broad application prospects and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

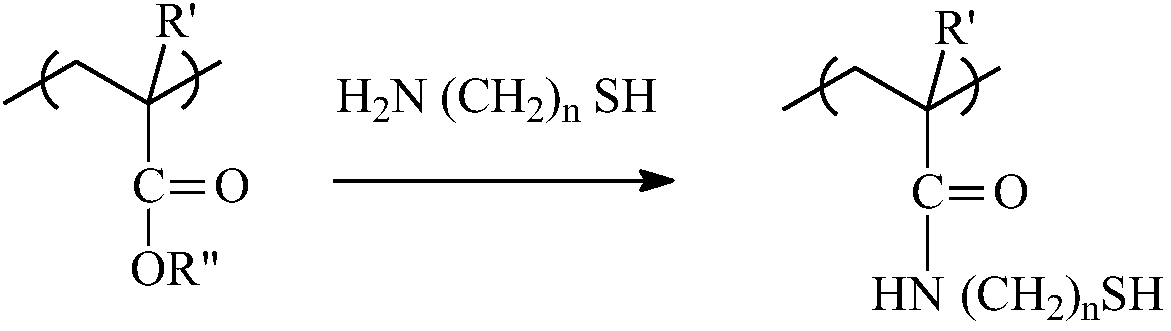

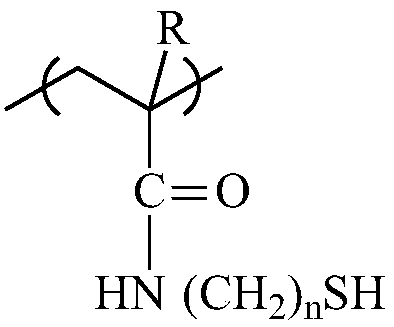

Method used

Image

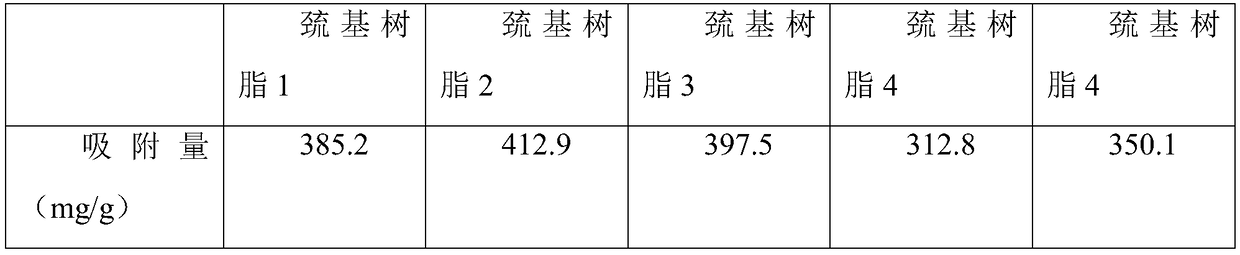

Examples

Embodiment 1

[0030] Mix 87.3g of methyl acrylate and 12.7g of divinylbenzene evenly, add 0.5g of azobisisobutyronitrile and stir to dissolve to obtain an oil phase; dissolve 2g of gelatin and 40g of sodium chloride in 400mL of deionized water, Obtain the water phase; add the oil phase to the water phase, start mechanical stirring, and disperse the oil phase into oil droplets, control the peak value of the oil droplet diameter distribution to 0.6mm, heat to 65°C and keep it for 6h, then raise the temperature to 70°C and Keep for 6 hours; stop heating, cool the system, filter to obtain the polymerized product, wash the polymerized product with hot water at 70°C for several times, and dry to obtain a white ball, which is recorded as white ball 1;

[0031] Add 8g of cysteamine hydrochloride to 50mL of acetone under the protection of nitrogen, add 7g of triethylamine dropwise under stirring, then add 10g of white ball 1, heat at 70°C for reflux reaction for 12h, cool, filter, and the obtained re...

Embodiment 2

[0033] Mix 50.1g of methyl acrylate, 5.9g of divinylbenzene, 5g of triallyl isocyanurate, 15g of toluene and 15g of liquid paraffin, add 0.3g of azobisisobutyronitrile and stir to dissolve it, and obtain Oil phase; dissolve 2g gelatin and 40g sodium chloride in 400mL deionized water to obtain a water phase; add the oil phase to the water phase, start mechanical stirring, and disperse the oil phase into small oil droplets, so that the diameter distribution of the oil droplets The peak value is 0.4mm. Heat the system to 65°C and keep it for 6h, then raise the temperature to 70°C and keep it for 6h; stop heating, let the system cool down, filter to get the polymerized product, and wash the polymerized product with 70°C hot water The second time, use a Soxhlet extractor to extract with acetone for 8 hours, and dry to obtain white balls, which are recorded as white balls 2;

[0034] Add 10g of cysteamine hydrochloride to 50mL of acetone under nitrogen protection, add 8.9g of trieth...

Embodiment 3

[0036] 50.1g of ethyl acrylate, 5.4g of divinylbenzene, 5.5g of ethylene glycol dimethacrylate, 15g of toluene and 15g of liquid paraffin were mixed evenly, and 0.3g of azobisisobutyronitrile was added and stirred to dissolve it to obtain Oil phase; 2g gelatin and 40g sodium chloride were dissolved in 400mL deionized water to obtain a water phase; the oil phase was added to the water phase, and mechanical stirring was started to disperse the oil phase into small oil droplets, and the diameter of the oil droplets was controlled to be 0.8mm, heated to 65°C and kept for 6h, then raised to 70°C and kept for 6h; stopped heating, cooled, filtered to obtain the polymerized product, and washed the polymerized product with hot water at 70°C for several times, and then used a Soxhlet extractor to wash with acetone Extracted for 8 hours, dried to obtain the white ball, denoted as white ball 3;

[0037] Add 8g of cysteamine hydrochloride to 50mL of absolute ethanol under nitrogen protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com