Preparation method and application of biological carbon fiber water treatment filler

A technology of biological carbon and water treatment, applied in biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc. Problems such as high production cost, to achieve the effect of not easy to store sludge, easy to clean and maintain, and easy to regenerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

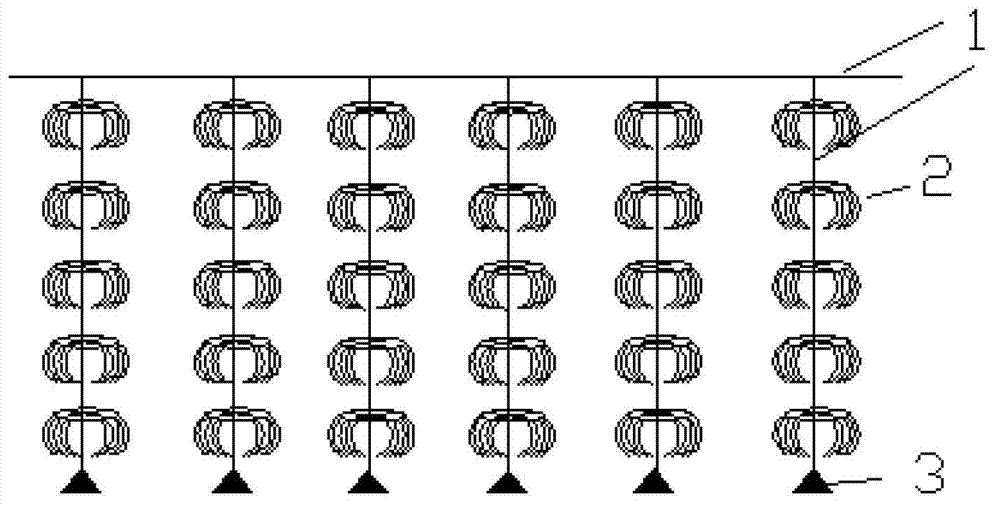

[0038] Such as figure 1 Shown, the preparation steps of a kind of disc-shaped biological carbon fiber water treatment filler of the present invention are as follows:

[0039] Step 1: Wind the carbon fiber into a bundle structure and put it into a Soxhlet extractor and degumming the surface with acetone for 10 hours;

[0040] Step 2: Rinse the degummed carbon fiber with deionized water to remove the acetone on the surface and the carbon fiber glue remaining on the surface of the carbon fiber to obtain bio-carbon fiber;

[0041] Step 3: cutting the bio-carbon fiber obtained in step 2 into several sections with a length of 40 cm to obtain a disc-shaped bio-carbon fiber water treatment filler 2;

[0042] Step 4: Place the prepared disc-shaped bio-carbon fiber water treatment filler 2 vertically in the water to form a biomimetic structure in the shape of aquatic plants, which floats with the flowing water.

[0043] Among them, the specific production method of the disc-shaped bio...

Embodiment 2

[0054]Another preparation method (not shown in the figure) of the bio-carbon fiber water treatment filler of the present invention, wherein, the disc-shaped bio-carbon fiber filler in Example 1 is replaced by a bundle-shaped bio-carbon fiber filler, and the bundle-shaped bio-carbon fiber water treatment filler The specific production method is as follows: the symmetrical center of the bio-carbon fiber cut into several sections is pasted horizontally on a non-woven fabric with a width of 64 cm and a width of 4 cm, and the non-woven fabric is used as a benchmark for fixing the carbon fiber to obtain a bundle-shaped bio-carbon fiber water treatment filler. , and a total of 55 parts of truncated bio-carbon fibers are pasted thereon. Other preparation methods are the same as Steps 1 to 4 of Example 1, and will not be described in detail here.

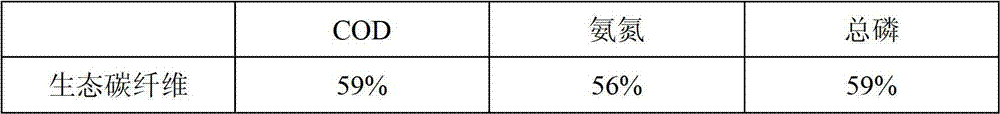

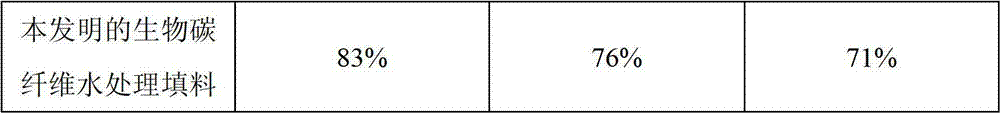

[0055] The above two biological carbon fiber water treatment fillers prepared by the present invention have better hydrophilicity, biocompa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com