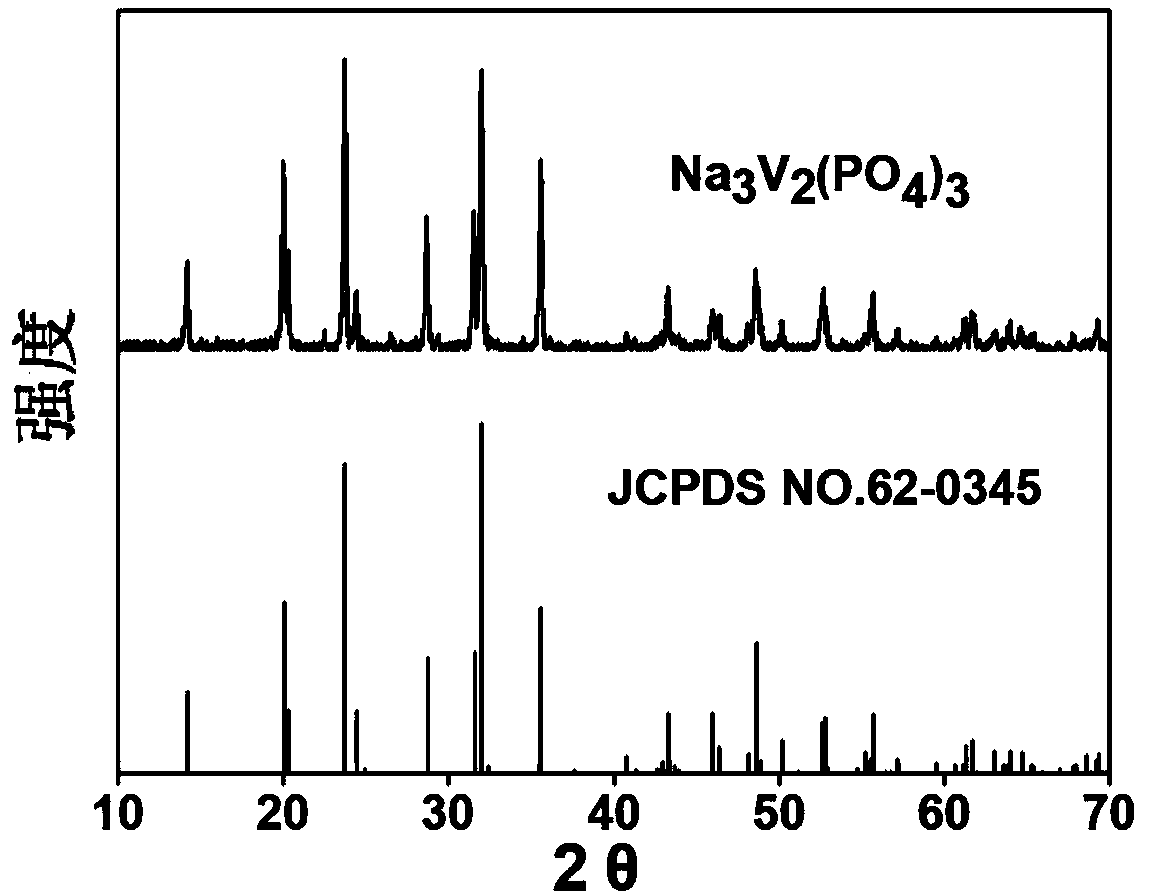

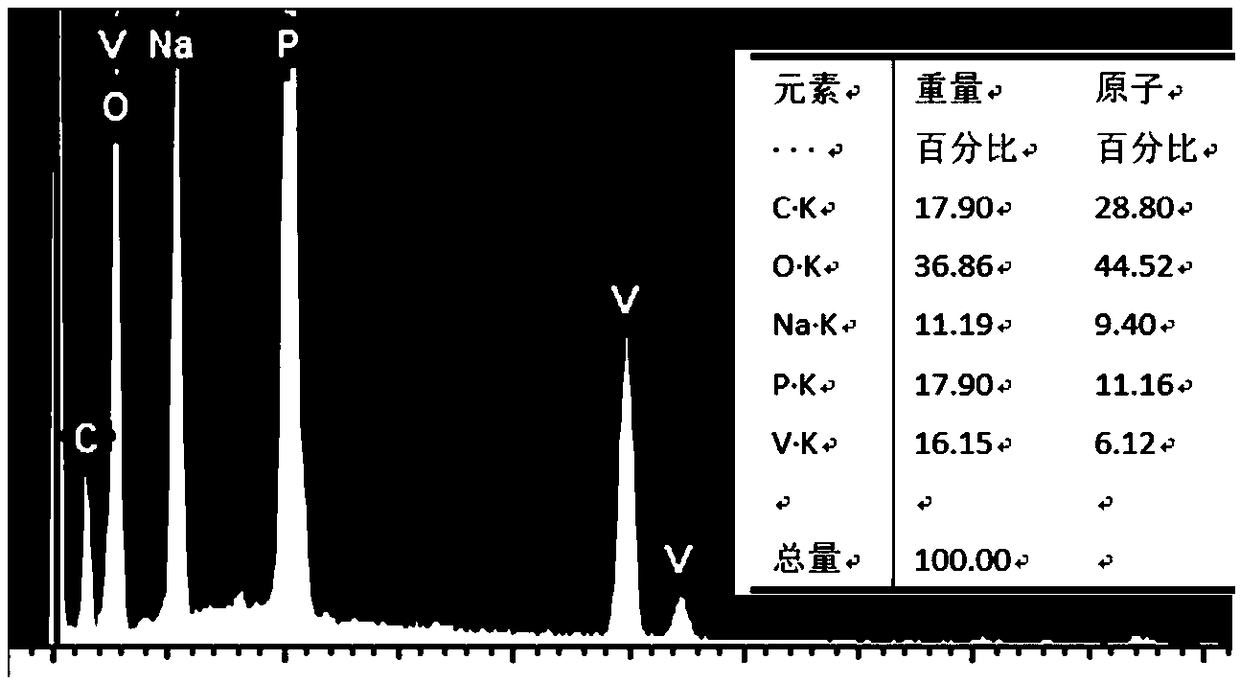

Na3V2(PO4)3/C composite material with quantum dot structure and preparation method thereof

A technology of carbon composite materials and sodium vanadium phosphate, which is applied in structural parts, electrical components, electrochemical generators, etc., can solve problems such as difficulties in electron and ion transmission, high price of graphene, and limitations of practical applications, etc., to optimize the electronic structure , excellent physical and chemical properties, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of sodium vanadium phosphate / carbon composite material with quantum dot structure, the steps are as follows:

[0043] (1) Soak 1.5g of bamboo pulp in 50ml of deionized water for 30min, add 0.75mg of polyethylene oxide and stir evenly, then ball mill for 1h to obtain wet bamboo pulp;

[0044] (2) Put 4.68g of sodium dihydrogen phosphate and 2.34g of ammonium metavanadate in a beaker, add 80ml of water, heat and dissolve in a water bath at 80°C and stir for 40min to obtain a uniform mixed solution;

[0045] (3) Gradually add the mixed solution of step (2) into the wet bamboo pulp of step (1) under stirring conditions, stir it at 80°C for 40min, place it in the reaction kettle for hydrothermal treatment at 180°C for 24h, dehydrate and separate it in After drying at 60°C, a black-green powder precursor is obtained;

[0046] (4) Treat the precursor obtained in step (3) under a nitrogen atmosphere at a rate of 3 °C / min to 350 °C for 5 hours, and then tak...

Embodiment 2

[0050] A preparation method of sodium vanadium phosphate / carbon composite material with quantum dot structure, the steps are as follows:

[0051] (1) Soak 1 g of poplar pulp in 50 ml of deionized water for 30 minutes, add 0.15 mg of sodium metaphosphate and stir evenly, then ball mill for 1 hour to obtain wet poplar pulp;

[0052] (2) Put 0.82g of sodium acetate, 2.44g of sodium metavanadate, and 3.96g of ammonium dihydrogen phosphate into a beaker, add 80ml of water, heat and dissolve in a water bath at 80°C and stir for 60min to obtain a uniform mixed solution;

[0053] (3) Gradually add the mixed solution of step (2) into the wet poplar pulp of step (1) under stirring conditions, stir it at 80°C for 30min, place it in the reactor for hydrothermal treatment at 160°C for 36h, dehydrate, separate and After drying at 60°C, a black-green powder precursor is obtained;

[0054] (4) Treat the precursor obtained in step (3) under a nitrogen atmosphere at a rate of 2 °C / min to 300 °...

Embodiment 3

[0057] A preparation method of sodium vanadium phosphate / carbon composite material with quantum dot structure, the steps are as follows:

[0058] (1) Soak 2 g of cotton pulp in 50 ml of deionized water for 30 minutes, add 1.5 mg of polyacrylamide and stir evenly, then ball mill for 1 hour to obtain wet cotton pulp;

[0059] (2) Put 1.84g of sodium vanadate, 3.96g of diammonium hydrogen phosphate, and 1.17g of ammonium metavanadate into a beaker, add 80ml of water, heat and dissolve in a water bath at 80°C and stir for 30min to obtain a uniform mixed solution;

[0060] (3) Gradually add the mixed solution of step (2) into the wet cotton pulp of step (1) under stirring conditions, stir it at 80°C for 60min, place it in the reaction kettle for hydrothermal treatment at 200°C for 12h, dehydrate and separate it in After drying at 60°C, a black-green powder precursor is obtained;

[0061] (4) Treat the precursor obtained in step (3) under a nitrogen atmosphere at a rate of 5 °C / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com