Method for preparing manganese dioxide-titanium carbide composite material through hydrothermal method and composite material prepared through method

A manganese dioxide, composite material technology, applied in secondary batteries, electrochemical generators, hybrid capacitor electrodes, etc., can solve problems such as affecting electrochemical performance, uneven surface distribution, and inability to control the structure of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

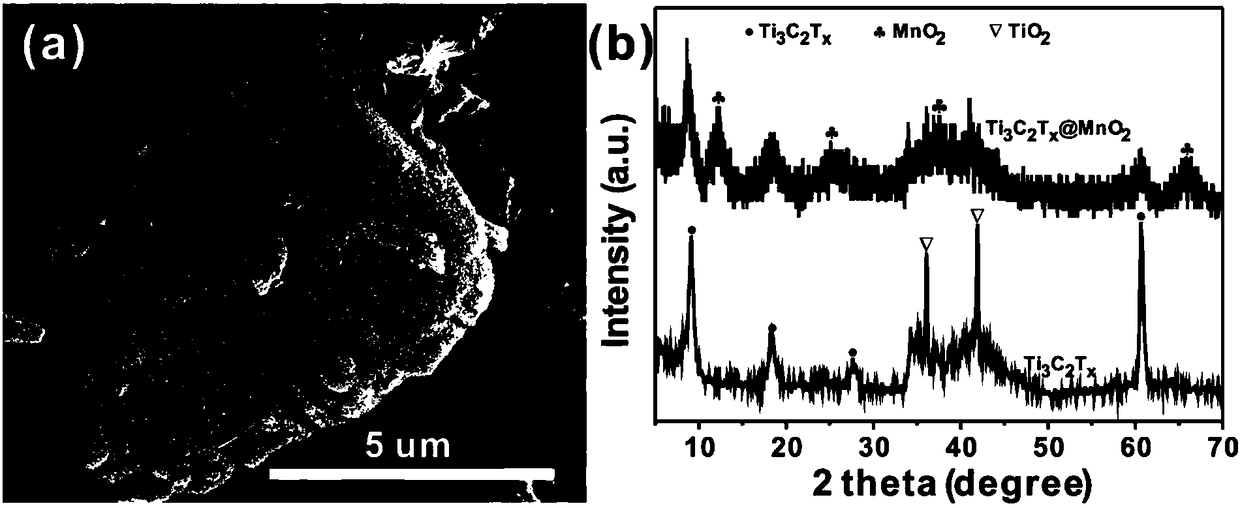

[0024] The preparation method of the present invention comprises the following steps:

[0025] Step 1, ternary layered Ti 3 AlC 2 Preparation of ceramic powder;

[0026] Synthesize ternary layered Ti according to the method of patent ZL201310497696.9 3 AlC 2 The preparation steps of the ceramic powder specifically include: firstly, mixing the experimental raw materials TiC, Ti, and Al powder according to the molar ratio of TiC:Ti:Al=2.0:1.0:1.2; secondly, mixing the mixture, alumina balls Alumina and absolute ethanol are ball milled in a corundum ball milling tank according to the mass ratio of 1:3:1, in which absolute ethanol is used as a ball milling aid, alumina balls are used as a grinding medium, the speed of the ball mill is 300r / min, and the wet ball milling is 4h Finally, dry in a constant temperature drying oven at 40°C for 24 hours; then, put the dried mixture into a corundum crucible, and carry out vacuum pressureless sintering in a vacuum hot-pressed carbon tub...

Embodiment 1

[0036] First, 30mg of Ti 3 C 2 @PDA nanopowder, add to 30mL ultrapure water, ultrasonically disperse for 30min; after the dispersion is uniform, add 31.6mg KMnO 4 , stirred for 1 h; transferred to a homogeneous hydrothermal kettle, put into a homogeneous reactor at 90° C. for 24 h; cooled naturally after the reaction, and the manganese dioxide / titanium carbide composite material was obtained.

Embodiment 2

[0038] First, 30mg of Ti 3 C 2 @PDA nanopowder, add to 30mL ultrapure water, ultrasonically disperse for 30min; after the dispersion is uniform, add 31.6mg KMnO 4 , stirred for 1 h; transferred to a homogeneous hydrothermal kettle, put into a homogeneous reactor at 100° C. for 24 h; cooled naturally after the reaction, and the manganese dioxide / titanium carbide composite material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com