method for synthesizing delta-MnO2 nanosheet array

A nanosheet array and synthesis method technology, which is applied in the field of nanomaterial preparation, can solve the problems of difficult control of powder crystal form and morphology, low material utilization rate, and poor product crystallinity, so as to improve material utilization rate and uniform morphology , The shape has no reunion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

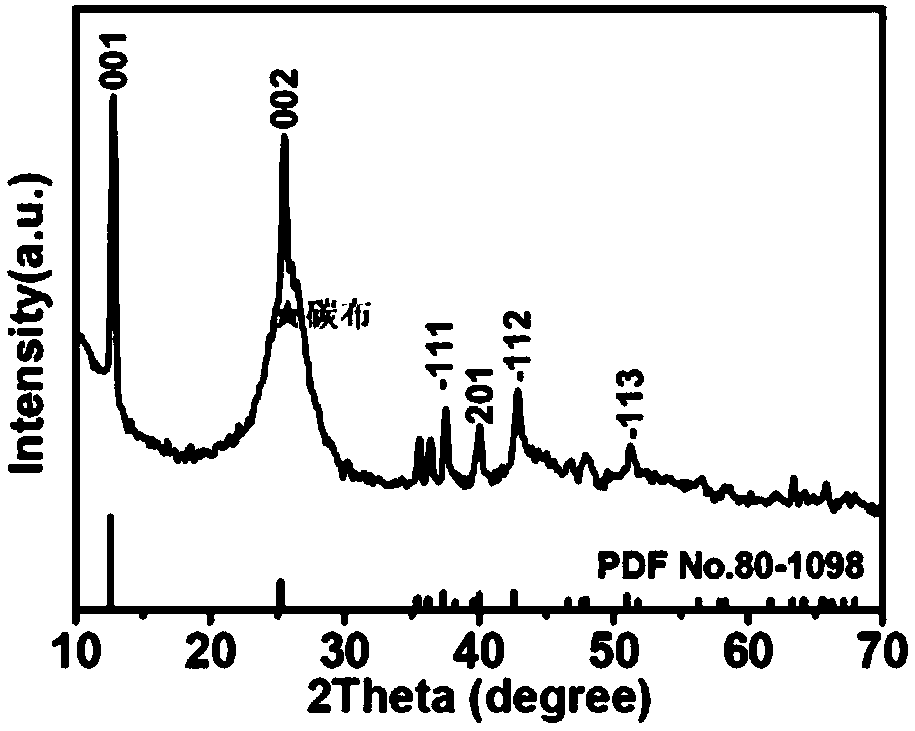

Embodiment 1

[0024] Press KMnO 4 The molar ratio with KF is 1:2, 1mmol KMnO 4 and 2mmol KF were respectively dissolved in 20ml deionized water, and the two solutions were evenly mixed, and 1M H 2 SO 4 Adjust the pH to 1, add a 3cm*3cm carbon cloth as the base material, and conduct a hydrothermal reaction at 100°C for 0.5h. After the reaction, the product is rinsed with deionized water and oven-dried at 60°C to obtain δ-MnO 2 Nanosheet arrays.

Embodiment 2

[0026] Press KMnO 4 The molar ratio with KF is 1:4, 1mmol KMnO 4 and 4mmolKF were respectively dissolved in 20ml deionized water, the two solutions were mixed evenly, and 1M H 2 SO 4 Adjust the pH to 1, add a 3cm*3cm carbon cloth as the base material, and conduct a hydrothermal reaction at 120°C for 0.5h. After the reaction, the product is washed with deionized water and dried in an oven at 60°C to obtain δ-MnO 2 Nanosheet arrays.

Embodiment 3

[0028] Press KMnO 4 The molar ratio with KF is 1:6, 1mmol KMnO 4 and 6mmolKF were respectively dissolved in 20ml deionized water, and the two solutions were evenly mixed, and the solution was washed with 1M H 2 SO 4 Adjust the pH to 1, add a 3cm*3cm carbon cloth as the base material, and conduct a hydrothermal reaction at 140°C for 0.5h. After the reaction, the product is washed with deionized water and dried in an oven at 60°C to obtain δ-MnO 2 Nanosheet arrays.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com