Preparation method of diaphragm, electrode and current collector integrated structure as well as preparation method of battery

A technology of current collectors and diaphragms, applied in structural parts, battery pack parts, separators/films/diaphragms/spacers, etc., to achieve the effect of enhancing bonding force, improving energy density, and reducing the thickness of conductive layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In this specific embodiment, a method for preparing an integrated structure of a diaphragm, an electrode, and a current collector is provided, comprising the following steps:

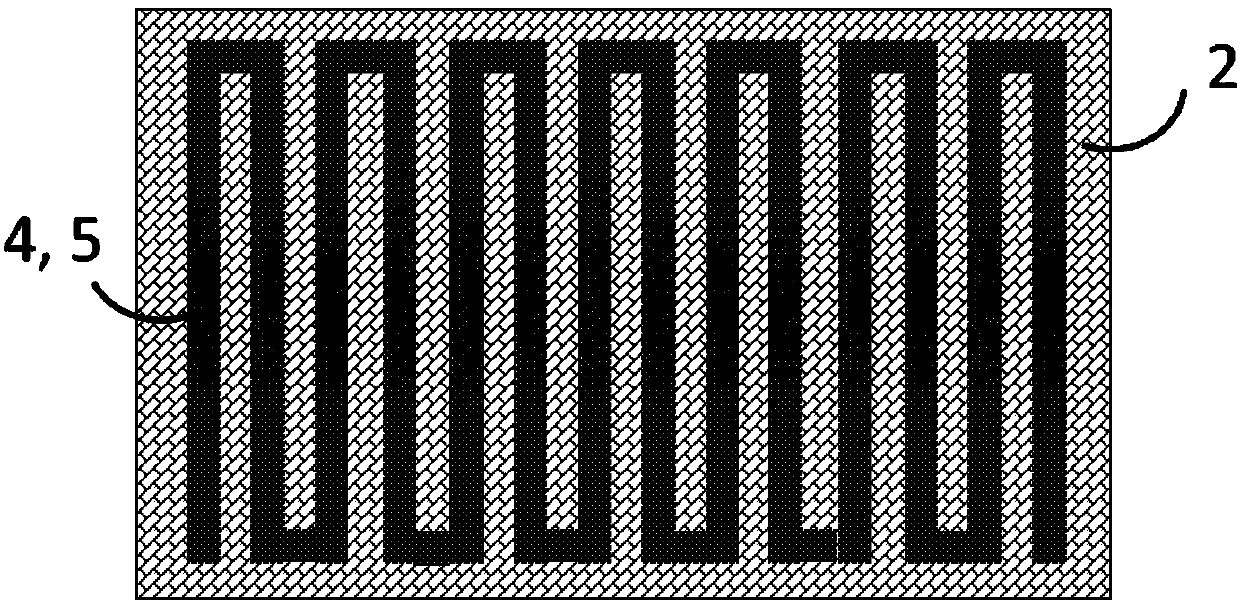

[0028] S1, using a separator as a substrate, printing electrode paste on the surface of the separator by printing technology or printing technology, so that the electrode paste is patterned and distributed on the surface of the separator.

[0029] S2, vacuum-drying the separator obtained in step S1 to solidify the electrode paste on the surface of the separator to form a patterned distribution of electrode materials.

[0030] S3, through vacuum coating technology or spray deposition technology, a layer of conductive film is plated or deposited on the entire surface of the patterned electrode material as a current collector, and then an integrated structure is obtained. The conductive thin layer obtained in this step evenly covers the electrode material to form a continuous conductive layer, there...

Embodiment 1

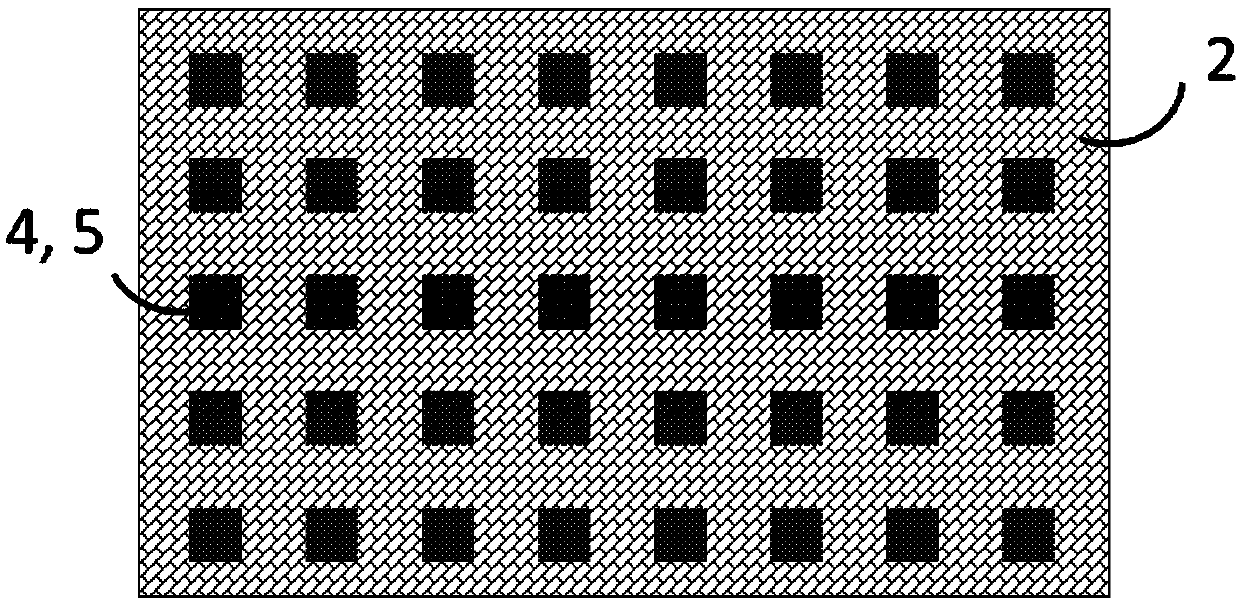

[0046] Select Celgard Model 2400 commercially available diaphragms (eg Figure 7 ), through the flat orifice printing process, the positive electrode paste of the battery is printed on one side of the separator. Among them, the thickness of the orifice plate is 30-500 μm, and the pattern of the orifice plate is distributed in a grid array; the positive electrode slurry is composed of lithium iron phosphate, conductive carbon black and PVDF in a ratio of 8:1:1. Subsequently, heat preservation at 80-150° C. for 2-24 hours, and solidify to obtain a separator substrate with grid-distributed electrode materials on the surface, and the size of the substrate is the size of A4 paper or equivalent. After curing, the diaphragm and the electrode material have a good bonding force, are not easy to fall off, and the diaphragm does not appear to be deformed.

[0047] Using the evaporation coating process, on the surface of the diaphragm base material on which the electrode material is prin...

Embodiment 2

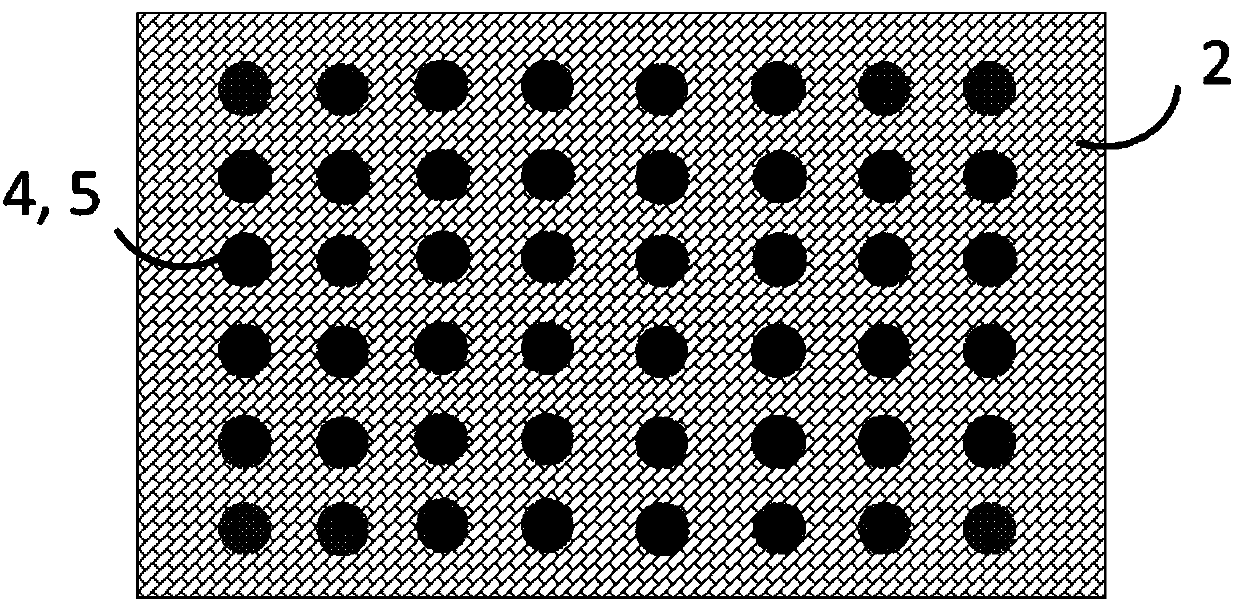

[0055] Select the Celgard 2400 commercial separator, and print the battery negative electrode slurry on one side of the separator through the curved surface roll-to-roll perforated plate printing process. Among them, the thickness of the orifice plate is 30-500 μm, and the pattern of the orifice plate presents a crescent lock array distribution; the negative electrode slurry is composed of graphite, conductive carbon black and binder PVDF in a ratio of 8:1:1. Subsequently, heat preservation at 80-150°C for 2-24 hours, and solidify to obtain a separator base material with a dot matrix pattern (the overall pattern is circular) distributed on the surface electrode material; the base material is a rollable film with a width ≥ 10 cm and a length ≥ 100cm. After curing, the diaphragm and the electrode material have a good bonding force, are not easy to fall off, and the diaphragm does not appear to be deformed.

[0056] A direct current sputtering coating process is used to plate a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com