Positive electrode material LiMn1-xFexPO4 / C and preparation method thereof

A cathode material, lithium source technology, applied in the field of lithium ion secondary batteries, can solve the problems of unstable manganese source batches, difficult calculation of metering ratios, complicated feeding, etc., and achieves easy to achieve large-scale production and high process controllability. , the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

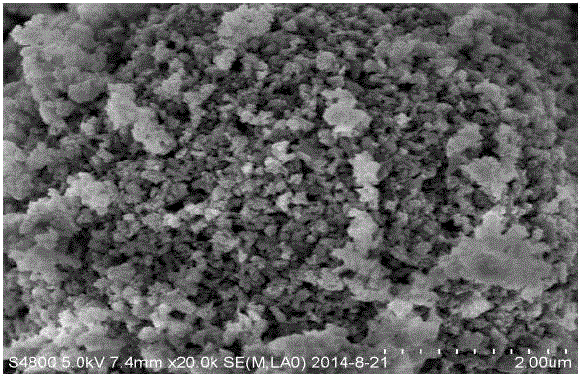

[0040] Through the preparation method provided by the invention, the positive electrode material LiMn can be prepared 1-x Fe x PO 4 / C. Compared with the traditional high-temperature solid-phase method, the preparation method provided by the invention is easy to operate, has high process controllability, and is easy to realize large-scale production.

[0041] Simultaneously, the present invention also provides a kind of cathode material LiMn 1-x Fe x PO 4 / C, the cathode material LiMn 1-x Fe x PO 4 / C is prepared by the preparation method provided by the present invention. The LiMn prepared by the aforementioned preparation method 1-x Fe x PO 4 The / C positive electrode material has high charge and discharge capacity, stable performance, long cycle life, and good electrochemical performance. It is the preferred material for power batteries that require particularly high consistency of materials.

Embodiment 1

[0044] Weigh MnCO according to the molar ratio Mn:Fe:P=0.85:0.15:1 3 、FePO 4 2H 2 O, phosphoric acid as raw material. MnCO 3 After shearing and dispersing, add it to phosphoric acid diluted to a certain degree, and add FePO after reacting for 15 minutes 4 , wet ball milling for 3 hours, spray drying to obtain a solid powder, put the solid powder into a saggar, and heat it up to 700°C for 6 hours at a rate of 3°C per minute in an air atmosphere to obtain the source A of this example. , denoted as A1.

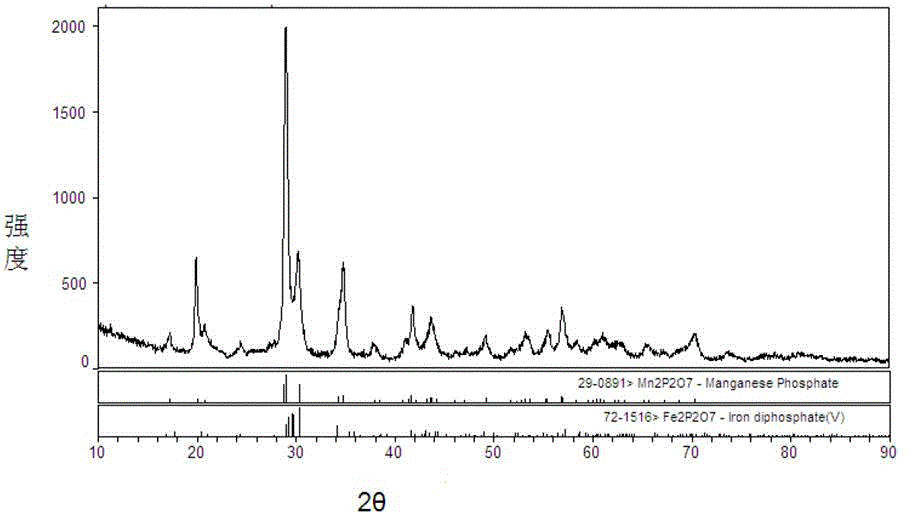

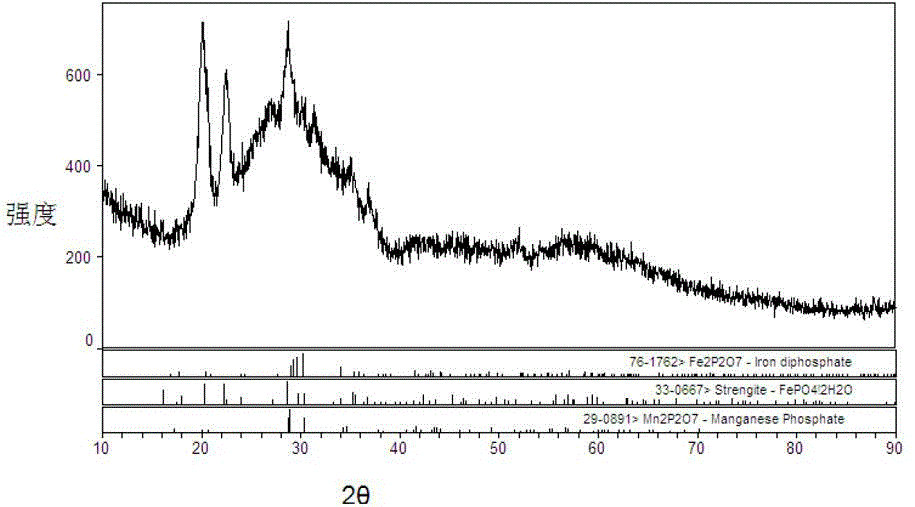

[0045] Carry out XRD test to A1, show that A1 is pure ferromanganous pyrophosphate.

[0046] Take 142.05g of the aforementioned A source A1, 26.14g of lithium carbonate, and 17.93g of glucose, use deionized water as the medium for wet ball milling for 3 hours, spray dry, and then transfer the solid powder into an atmosphere furnace under the protection of nitrogen, at a temperature of 3°C per minute After the temperature reaches 700°C, it is roasted at a constant temperatur...

Embodiment 2

[0048] Weigh MnCO according to the molar ratio Mn:Fe:P=0.65:0.35:1 3 、FePO 4 2H 2 O, phosphoric acid as raw material. MnCO 3 After shearing and dispersing, add it to phosphoric acid diluted to a certain degree, and add FePO after reacting for 15 minutes 4 , wet ball milling for 3 hours, spray drying to obtain a solid powder, put the solid powder into a saggar, and heat it up to 700°C for 6 hours at a rate of 3°C per minute in an air atmosphere to obtain the source A of this example. , recorded as A2.

[0049] Carry out XRD test to A2, show that A2 is pure ferromanganous pyrophosphate.

[0050] Take 142.23g of the aforementioned A source A2, 26.14g of lithium carbonate, and 17.93g of glucose, and use deionized water as the medium for wet ball milling for 2 hours, spray dry, and then transfer the solid powder into an atmosphere furnace under the protection of nitrogen, at a temperature of 3°C per minute. After the temperature reaches 700°C, it is roasted at a constant temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com