Positive plate diaphragm bag as well as a laminated lithium ion battery and manufacturing method thereof

A lithium-ion battery and positive electrode technology, applied in the field of lithium-ion batteries, can solve the problems of damaging the battery electrode and structure, reducing the electrochemical performance of the battery, and wrinkling the battery surface, so as to improve the capacity and avoid poor electrical performance. The effect of small solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

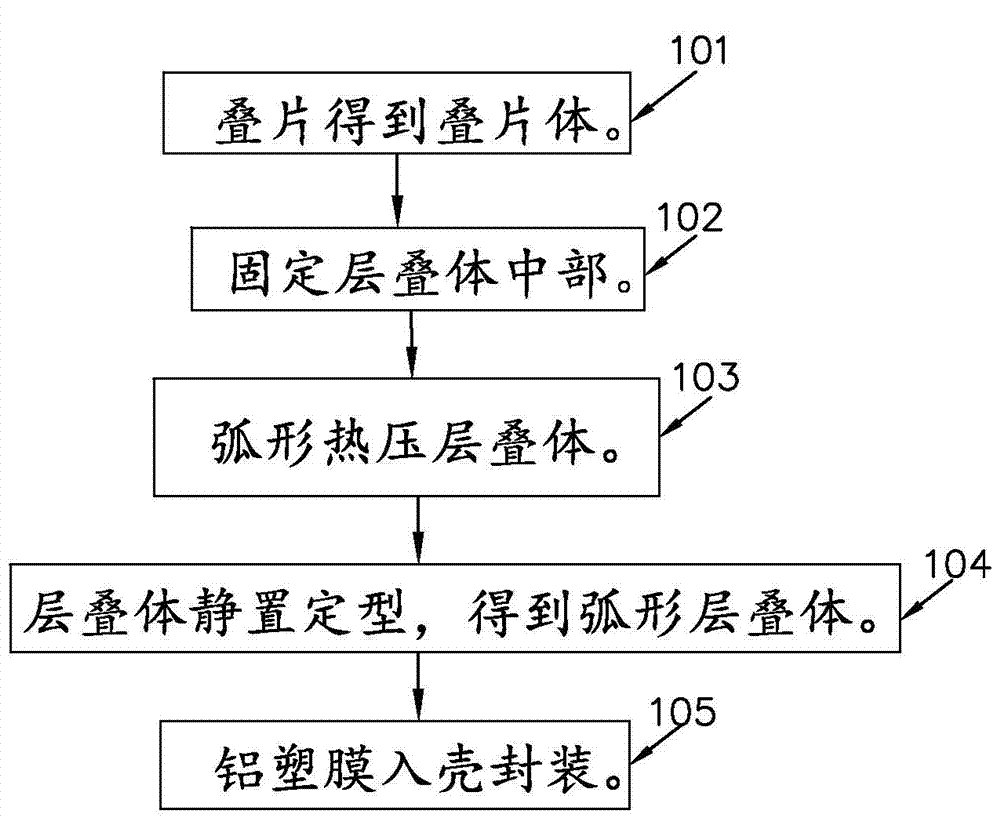

[0056] In the first aspect, a method for preparing a laminated lithium-ion battery provided in an embodiment of the present invention includes:

[0057] Laminating the negative electrode sheet and the positive electrode sheet to obtain a laminated electric core body, and there is a separator layer between any of the positive electrode sheets and negative electrode sheets in the laminated electric core body,

[0058] Fix the middle part of the laminated electric core body, place the laminated electric core body naturally on the top of an arc-shaped support, heat press the laminated electric core body on the arc-shaped support for a predetermined time, and make the laminated electric core body Each diaphragm layer in the cell body is bonded to the positive electrode sheet and the negative electrode sheet adjacent to the diaphragm layer;

[0059] Resting the laminated electric core body on the arc-shaped support until the laminated electric core body is shaped into an arc matchin...

Embodiment 1

[0157] see Figure 1-18 As shown, the present embodiment provides a preparation process for laminated lithium-ion batteries, which mainly includes the following steps:

[0158] Step 101: lamination to obtain a laminated body.

[0159] In this step, the negative electrode sheet 1301 and the positive electrode sheet 500 are laminated to obtain a laminated cell body 801 . A separator layer is separated between any layer of the positive electrode sheet 500 and the negative electrode sheet 1301 in the obtained laminated electric core body 801 . 1

[0160] In this step, it can be realized by laminating a single positive electrode sheet 500 , a separator sheet, and a negative electrode sheet 1301 according to the prior art.

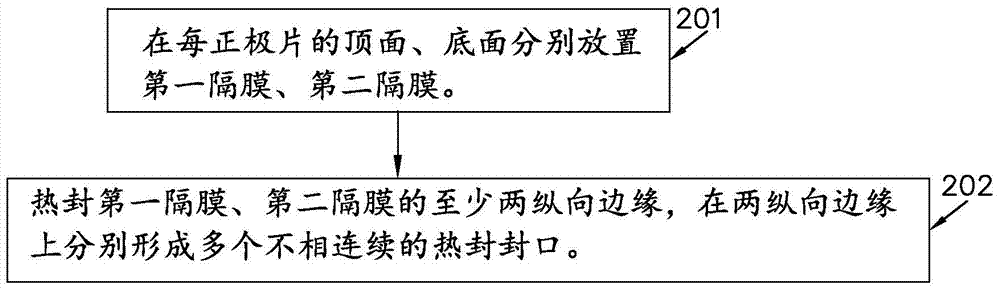

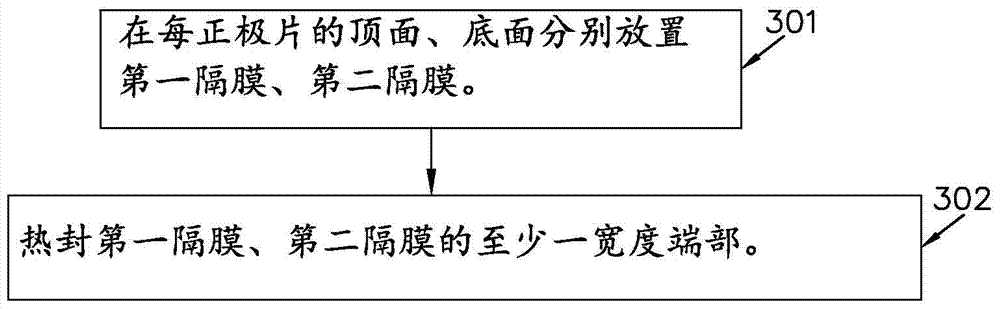

[0161] As an illustration of the implementation of this step, the inventor provides the following lamination technical solutions:

[0162] Put the positive electrode sheet 500 into the membrane bag to obtain the positive electrode sheet diaphragm bag, so tha...

Embodiment 2

[0257] see Figure 13 As shown, the laminated lithium-ion battery of the lithium-ion battery provided in this embodiment includes: an arc-shaped laminated battery core body and an aluminum-plastic film casing. The structure and connections of each part are as follows:

[0258] For the structure of the arc-shaped laminated cell body, see Figure 14 As shown, the arc-shaped laminated cell body is composed of stacked naturally-shaped arc-shaped negative electrode sheets 1301 and positive electrode sheets 500. There is a natural arc-shaped diaphragm layer separated between any positive electrode sheet 500 and negative electrode sheet 1301. Each separator layer is bonded to the positive electrode sheet 500 and the negative electrode sheet 1301 adjacent to the separator layer respectively. The specific preparation process can be referred to the corresponding introduction in Example 1, but is not limited to.

[0259] For the structure of the aluminum-plastic film shell, see Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com