Preparation method for lithium vanadium phosphate slurry-based positive electrode of lithium ion battery

A lithium ion battery, lithium vanadium phosphate technology, applied in battery electrodes, electrode manufacturing, electrode current collector coating, etc., can solve problems such as inability to achieve rate performance, and achieve inhibiting excessive growth, improving conductivity, and increasing rate and rate. The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Li 3 V 2 (PO 4 ) 3 The preparation method of / C slurry and electrode sheet, comprises the following steps:

[0042] a, the 85wt% Li 3 V 2 (PO 4 ) 3 / C, 10wt% acetylene black and 5wt% polyvinylidene fluoride PVDF were dispersed in 10wt% N-methyl-2-pyrrolidone and ball milled for 5h to obtain a slurry (the total weight percentage was 110%);

[0043] b. Coating the slurry on the current collector, drying in vacuum at 120°C for 12 hours to obtain the electrode sheet;

[0044] c. Cut the electrode sheet into an area of 0.8cm 2 small pole pieces;

[0045] d. Assemble the electrode pieces into a button cell in an argon-filled glove box, and conduct electrochemical performance tests.

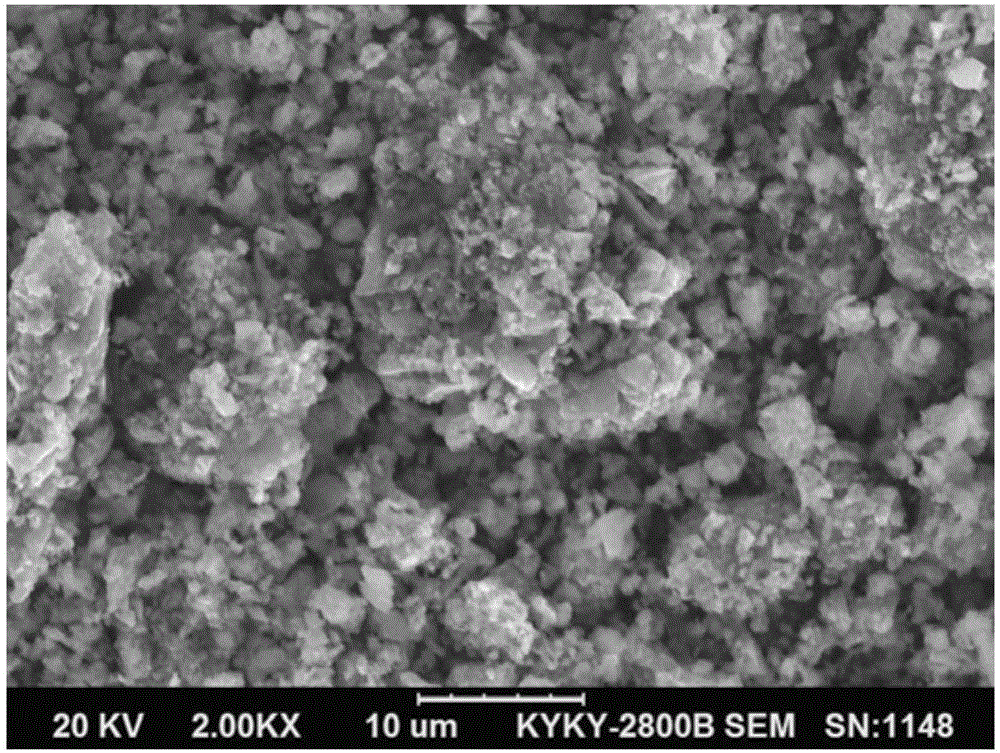

[0046] Figure 4 (a) is the scanning electron micrograph of the pole piece prepared in embodiment 1, from which it can be seen that there is Li of large particle size in the pole piece 3 V 2 (PO 4 ) particles.

[0047] Figure 4 (b) is the cycle performance diagram of the battery...

Embodiment 2

[0049] Li 3 V 2 (PO 4 ) 3 The preparation method of / C slurry and electrode sheet, comprises the following steps:

[0050] a, the 84wt% Li 3 V 2 (PO 4 ) 3 / C, 10wt% acetylene black, 5wt% PVDF and 1wt% LiCoO 2 Disperse in 10% N-methyl-2-pyrrolidone and ball mill for 5 hours to obtain a slurry, the total weight percentage is 110%;

[0051] b. Coating the slurry on the current collector, drying in vacuum at 120°C for 12 hours to obtain the electrode sheet;

[0052] c. Cut the electrode sheet into an area of 0.8cm 2 small pole pieces;

[0053] d. Assemble the electrode pieces into a button cell in an argon-filled glove box, and conduct electrochemical performance tests.

[0054] Figure 5 (a) is the scanning electron micrograph of the pole piece prepared in embodiment 2, from which it can be seen that there is still Li of large particle size in the pole piece 3 V 2 (PO 4 ) 3 / C particles, but with a reduced number of large particles.

[0055] Figure 5 (b) is th...

Embodiment 3

[0057] Li 3 V 2 (PO 4 ) 3 The preparation method of / C slurry and electrode sheet, comprises the following steps:

[0058] a, the 82wt% Li 3 V 2 (PO 4 ) 3 / C, 10wt% acetylene black, 5wt% PVDF and 3wt% LiCoO 2 Disperse in 10% N-methyl-2-pyrrolidone and ball mill for 5 hours to obtain a slurry (the total weight percentage is 110%);

[0059] b. Coating the slurry on the current collector, drying in vacuum at 120°C for 12 hours to obtain the electrode sheet;

[0060] c. Cut the electrode sheet into an area of 0.8cm 2 small pole pieces;

[0061] d. Assemble the electrode pieces into a button cell in an argon-filled glove box, and conduct electrochemical performance tests.

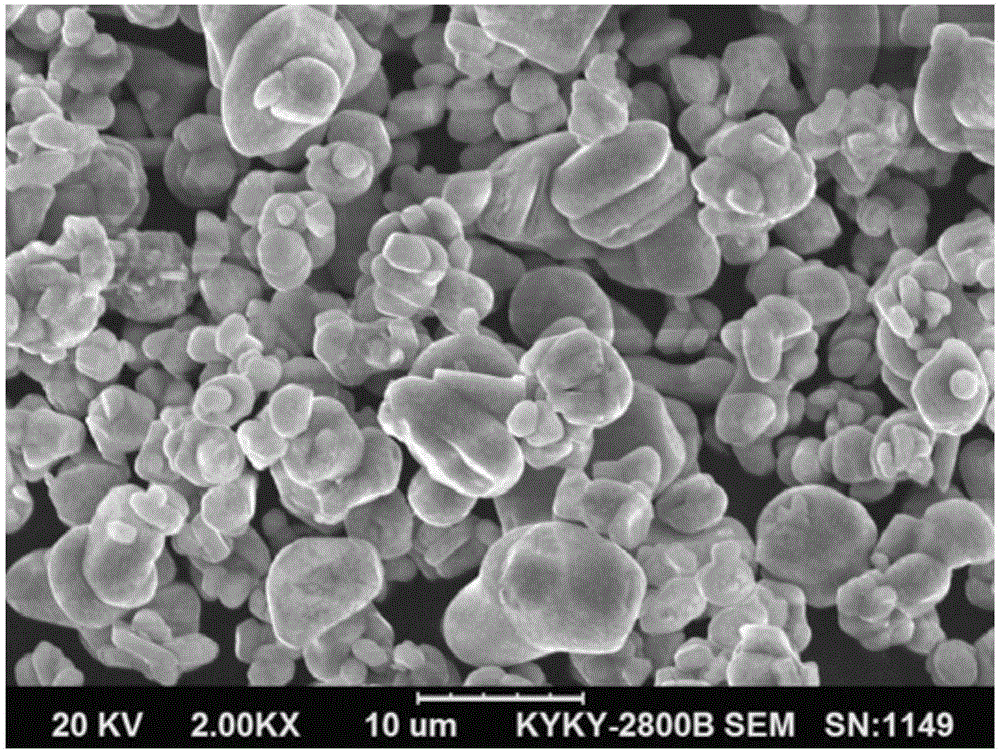

[0062] Image 6 (a) is the scanning electron micrograph of the pole piece prepared in embodiment 3, from which it can be seen that Li in the pole piece 3 V 2 (PO 4 ) 3 / C particles are smaller and evenly distributed.

[0063] Image 6 (b) is the cycle performance diagram of the battery assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com