Mineral slurry make-up base and preparation method for same

A technology of isolation cream and mineral slime, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problem of destroying the emulsification system of cosmetics, and achieve the effect of enhancing skin immunity, preventing damage, and enhancing skin resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

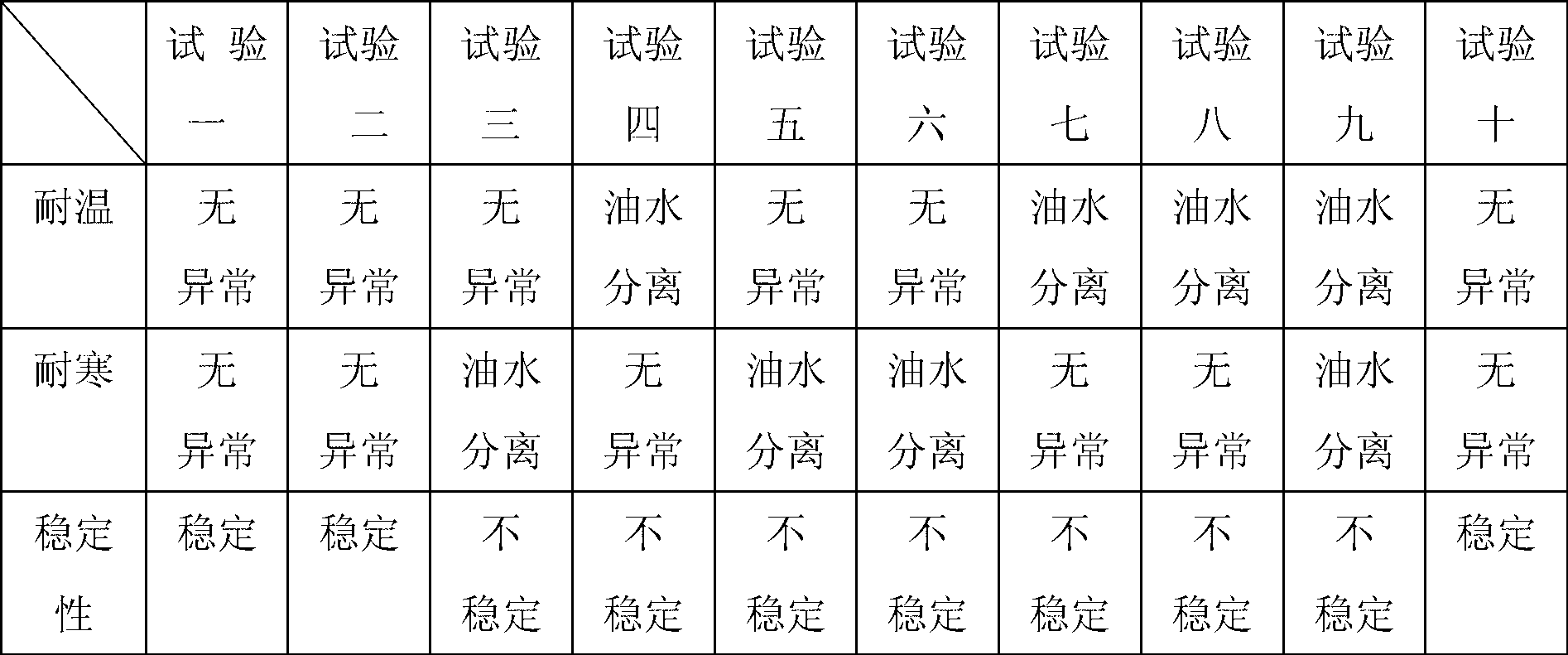

Examples

specific Embodiment approach 1

[0009] Specific embodiment one: a kind of mineral slime isolation cream of this embodiment is made of 8%~10% Wudalianchi volcanic mineral mud extract, 3%~5% squalane, 5%~10% butanediol, 2.5% by weight percentage %~3% titanium dioxide, 5%~10% isononyl isononanoate, 3%~3.5% polydimethylsiloxane, 0.5%~2% cyclopentasiloxane, 1.5%~2.5 % Betaine, 0.5%~3% Cetyl PEG / PPG-10 / 1 Dimethicone, 2%~5% Silica Dimethylsilylate, 1.5%~2.5% Ginkgo Biloba Extract , 1.5%~2.5% white chamomile flower extract, 1%~3% bisabolol, 3%~5% allantoin, 0.05%~0.5% methylparaben, 0.05%~0.5% paraben Ester, 1.5%~2.5% phenoxyethanol, 0.5%~2% sodium chloride, 0.01%~0.05% essence, 0.01%~0.05% CI772889 and the rest are processed Wudalianchi mineral water after emulsification and homogenization.

[0010] The cetyl PEG / PPG~10 / 1 polydimethylsiloxane described in this embodiment is an emulsifier.

[0011] The CI772889 described in this embodiment is a color material, and its Chinese name is chromium oxide green.

[0012...

specific Embodiment approach 2

[0020] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the Wudalianchi mineral water after the described treatment obtains by following treatment: 1. remove iron and manganese: adopt air aeration method to Wudalianchi with aeration device Raw water (natural mineral water gushing out of Wudalianchi) is aerated for 4 hours, left to stand for 72 hours, and the supernatant is collected, and the bottom sediment is drained to obtain the raw water of Wudalianchi after removing iron and manganese; ②Sterilization and filtration: the steps ① The obtained raw water of Wudalianchi after removal of iron and manganese is sterilized by ultraviolet rays through pipelines, and filtered through a microporous membrane filtration device to obtain treated Wudalianchi mineral water. Others are the same as the first embodiment.

[0021] The Wudalianchi mineral water described in this embodiment belongs to the iron-siliceous carbonate bicarbonate magnes...

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the described Wudalianchi volcanic slime extract is completed according to the following steps: 1. remove sundries: first remove the Wudalianchi volcanic slime Remove the sundries, then divide it into mud blocks with a diameter of 5cm~8cm, and after drying in the shade, you can get the mud blocks after removing the sundries; The machine is crushed into mud particles with a diameter of 5mm~10mm, and then transferred to an ultrafine powder machine, and crushed under the conditions of a feed speed of 1400~1500 rpm and an air flow of 1800~2000 rpm. 300 mesh to 600 mesh, that is, dry slime powder is obtained; ③Extraction: Add the processed Wudalianchi mineral water to the dry slime powder, and the mass ratio of the treated Wudalianchi mineral water to the dry slime powder is 20 : 1, adjust pH to 5.0~7.0 with hydrochloric acid or sodium hydroxide, fully stir, place 24h, ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com