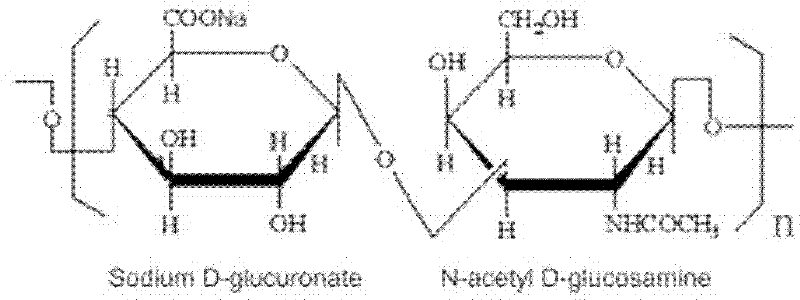

Purification method for sodium hyaluronate

A sodium hyaluronate and purification method technology, applied in the field of sodium hyaluronate purification, can solve the problems of high energy consumption, unfavorable large-scale production operations, and long time, and achieve the effects of increasing yield, reducing adverse reactions, and reducing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

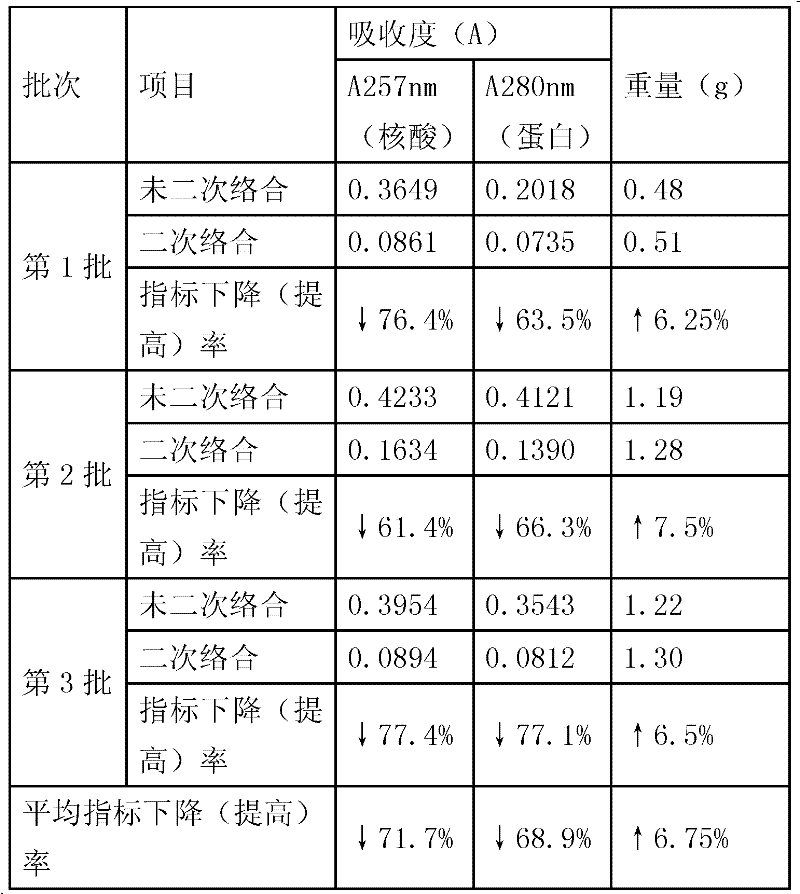

Embodiment 1

[0026] Prepare sodium hyaluronate with the existing extraction method, take cockscomb enzymatic hydrolysis liquid and filter 400ml of medicinal liquid after activated carbon adsorption and filtration, take 1.6g of CPC and add a little water to dissolve, stir and mix with medicinal liquid, and complex and precipitate for 30 minutes. After the complex precipitation is complete, let the precipitate stand still, discard the supernatant, and prepare 65ml of 0.4mol / L dissociation solution to dissociate the complex precipitation for 5 hours. After the dissociation is completed, take an appropriate amount of purified water and dilute the dissociation solution To 260ml, stir while diluting, the complexed precipitate begins to precipitate, stop diluting when the dissociated solution is diluted to 390ml, continue to stir the complexed precipitate for 30min for secondary complexation, discard the supernatant after the complexed precipitation is completed, and wash the precipitate After one...

Embodiment 2

[0028] Sodium hyaluronate was prepared by the existing extraction method, and 1000ml of the medicinal solution was taken from the cockscomb enzymatic hydrolysis solution once activated carbon was adsorbed and filtered, 4.0g of CPC was dissolved in a little water, stirred and mixed with the medicinal solution, and complexed and precipitated for 30 minutes. After the complex precipitation is complete, let the precipitate stand still, discard the supernatant, and prepare 163ml of 0.4mol / L dissociation solution to dissociate the complex precipitation for 4 hours. After the dissociation is complete, take an appropriate amount of purified water and dilute the dissociation solution to 650ml, stirring while diluting, the complexed precipitate begins to precipitate, stop diluting when the dissociated solution is diluted to 1250ml, continue to stir the complexed precipitate for 30min for secondary complexation, discard the supernatant after the complexed precipitation is completed, and wa...

Embodiment 3

[0030] Sodium hyaluronate was prepared by the existing extraction method, and 1000ml of the medicinal solution was taken from the cockscomb enzymatic hydrolysis solution once activated carbon was adsorbed and filtered, 4.0g of CPC was dissolved in a little water, stirred and mixed with the medicinal solution, and complexed and precipitated for 30 minutes. After the complex precipitation is complete, let the precipitate stand still, discard the supernatant, and prepare 163ml of 0.4mol / L dissociation solution to dissociate the complex precipitation for 5 hours. After the dissociation is complete, take an appropriate amount of purified water and dilute the dissociation solution to 650ml, stirring while diluting, the complexed precipitate begins to precipitate, stop diluting when the dissociated solution is diluted to 1180ml, continue to stir the complexed precipitate for 30min for secondary complexation, discard the supernatant after the complexed precipitation is completed, and wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com