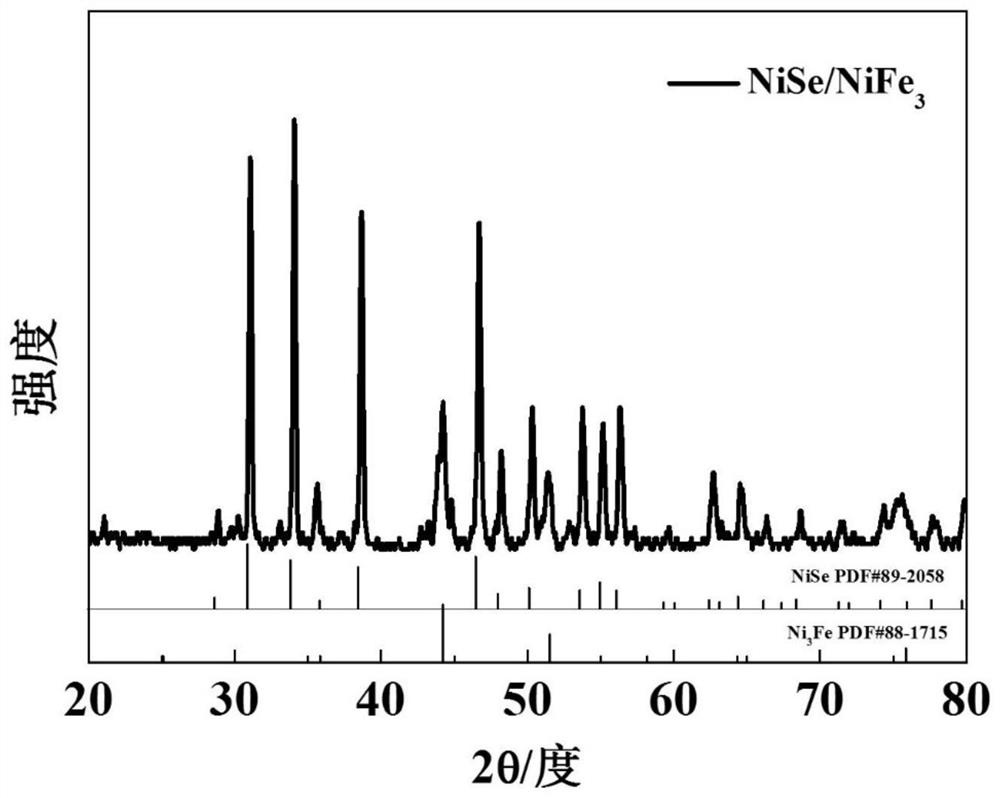

Nickel selenide/ferronickel substrate material as well as preparation method and application thereof

A base material, a technology of nickel selenide, applied in the field of electrocatalytic materials, can solve the problem of low catalytic performance of nickel selenide, etc., and achieve the effects of simple synthesis path, low reaction temperature and low ionic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention discloses a preparation method of nickel selenide / nickel-iron base material, which comprises the following steps:

[0032] Step 1: Pretreatment of foamed ferronickel; pretreatment includes: first, ultrasonically clean the foamed ferronickel cut into 1.5cm×4cm in acetone solution for 10 to 15 minutes, and then place it in an appropriate concentration of 1 to 2mol / L Ultrasonic cleaning in hydrochloric acid solution for 10-15s, then alternately washing with absolute ethanol and ultrapure water for 2-3 times, and finally vacuum-drying at 30-40°C for 8-10 hours before use;

[0033] Step 2: Pour 75-80 mg of selenium powder into 2-3 mL of hydrazine hydrate solution with a mass concentration of 50%, and stir evenly until a wine-red transparent solution A appears; preferably, magnetic stirring is used for stirring, and the temperature is 60-60 65°C, the time is 30-40min, and the speed is 400-500r / min;

[0034] Step 3: Pour 5.77-17.42 mg of sodium lauryl sulfate an...

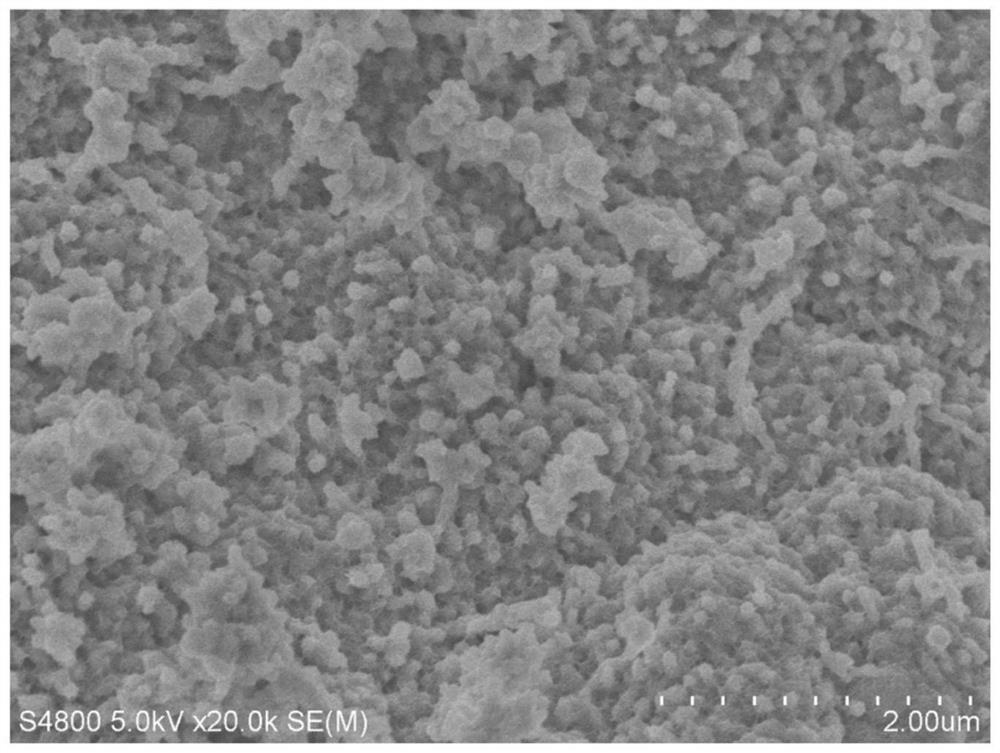

Embodiment 1

[0039] 1) Pretreatment of foamed ferronickel: First, ultrasonically clean the foamed ferronickel with a size of 1.5cm×4cm in acetone solution for 10 minutes, then pour it into the prepared 1mol / L hydrochloric acid and ultrasonically clean it for 15s, and then separate Rinse twice alternately with absolute ethanol and ultrapure water, and finally vacuum-dry at 34°C for 10 hours before use;

[0040] 2) Pour 75mg of selenium powder into 2mL of hydrazine hydrate solution with a mass concentration of 50%, and magnetically stir at a speed of 400r / min at a temperature of 60°C for 40min until a wine-red transparent solution A appears;

[0041] 3) Pour 5.77mg of sodium lauryl sulfate and 36.18mg of vanadium trichloride into a 50mL p-polyphenyl liner filled with absolute ethanol solvent, and stir at room temperature for 20min to obtain solution B, Then pour solution A into solution B, put the pretreated ferronickel foam into mixed solution C, and carry out hydrothermal reaction at a tem...

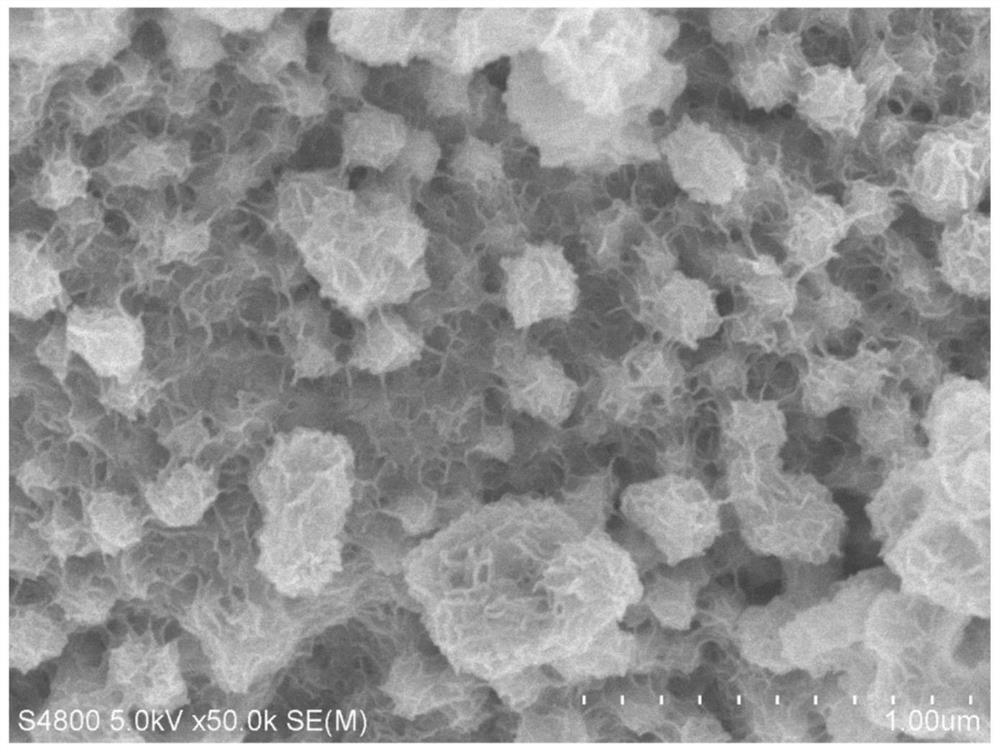

Embodiment 2

[0046] 1) Foamed ferronickel pretreatment: First, ultrasonically clean the foamed ferronickel with a size of 1.5cm×4cm in acetone solution for 11 minutes, then pour it into the prepared 2mol / L hydrochloric acid for ultrasonic cleaning for 12s, and then use anhydrous Alternately wash with ethanol and ultrapure water for 3 times, and finally vacuum-dry at 40°C for 8 hours before use;

[0047] 2) Pour 76mg of selenium powder into 3mL of hydrazine hydrate solution with a mass concentration of 50%, and magnetically stir at a speed of 450r / min at a temperature of 61°C for 35min until a wine-red transparent solution A appears;

[0048] 3) Pour 8.1mg of sodium lauryl sulfate and 37.75mg of vanadium trichloride into a 50mL p-polyphenyl liner filled with absolute ethanol solvent, and stir at room temperature for 19min to obtain solution B, Then pour solution A into solution B, put the pretreated foamed ferronickel into mixed solution C, and carry out hydrothermal reaction at a temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com