Method for manufacturing high-strength low-heat conduction coefficient xonotlite heat-insulating material

A low thermal conductivity, xonotlite technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of low thermal conductivity, difficult xonotlite crystals, difficult to produce, etc., to achieve uniform material and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for making a xonotlite type thermal insulation and fireproof board with high strength and low thermal conductivity comprises the following steps:

[0056] 1. The siliceous raw material body and the calcium raw material are prepared according to the Ca / Si ratio (molar ratio) of 0.5 to make a slurry;

[0057] 2. Pre-react the slurry obtained in step 1, the reaction time is 3 hours, and the reaction temperature is 30°C, so that it can fully form the tobermorite slurry;

[0058] 3. Add the slurry colloid obtained in step 2 to the active-repellent material to thicken and increase the activity

[0059] 4. The slurry obtained in step 3 is re-mixed, and the Ca / Si ratio (molar ratio) is 0.8, so that it can fully form the xonotlite composition;

[0060]5. Pour the slurry obtained in step 4 into a high-temperature and high-pressure reactor for synthesis. The steam temperature used is 180°C, the steam pressure is 1.8mpa, and the reaction time is 2 hours to ...

Embodiment example 2

[0064] A method for making a xonotlite type thermal insulation and waterproof board with high strength and low thermal conductivity comprises the following steps:

[0065] 1. The siliceous raw material body and the calcium raw material are prepared according to the Ca / Si ratio (molar ratio) of 1.1 to make a slurry;

[0066] 2. Pre-react the slurry obtained in step 1, the reaction time is 120 hours, and the reaction temperature is 120°C, so that it can fully form the tobermorite slurry;

[0067] 3. Add the slurry colloid obtained in step 2 to an active-repellent material to thicken and increase activity;

[0068] 4. The slurry obtained in step 3 is re-mixed, and the Ca / Si ratio (molar ratio) is 1.1, so that it can fully form the xonotlite composition;

[0069] 5. Pour the slurry obtained in step 4 into a high-temperature and high-pressure reactor for synthesis. The steam temperature used is 400°C, the steam pressure is 3.6mpa, and the reaction time is 10 hours to o...

Embodiment example 3

[0073] A method for making a xonotlite type thermal insulation and fireproof board with high strength and low thermal conductivity comprises the following steps:

[0074] 1. The siliceous raw material body and the calcareous raw material are prepared according to the Ca / Si ratio (molar ratio) of 0.8 to make a slurry;

[0075] 2. Pre-react the slurry obtained in step 1, the reaction time is 30 hours, and the reaction temperature is 60°C, so that it can fully form the tobermorite slurry;

[0076] 3. Add the slurry colloid obtained in step 2 to an active-repellent material to thicken and increase activity;

[0077] 4. The slurry obtained in step 3 is re-mixed, and the Ca / Si ratio (molar ratio) is 0.9, so that it can fully form the xonotlite composition;

[0078] 5. Pour the slurry obtained in step 4 into a high-temperature and high-pressure reactor for synthesis. The steam temperature used is 300°C, the steam pressure is 3mpa, and the reaction time is 4 hours to obtain an extrem...

PUM

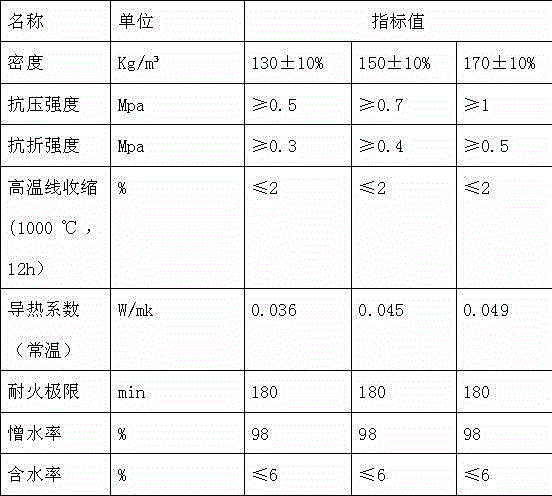

| Property | Measurement | Unit |

|---|---|---|

| Body dense | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Body dense | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com