High-weather-resistance cable material for railway passenger trains and preparation method thereof

A railway passenger car, high weather resistance technology, applied in rubber insulators, organic insulators and other directions, can solve the problems of poor weather resistance, prone to aging and cracking, etc., and achieve the effect of long service life, small changes in physical and mechanical properties, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

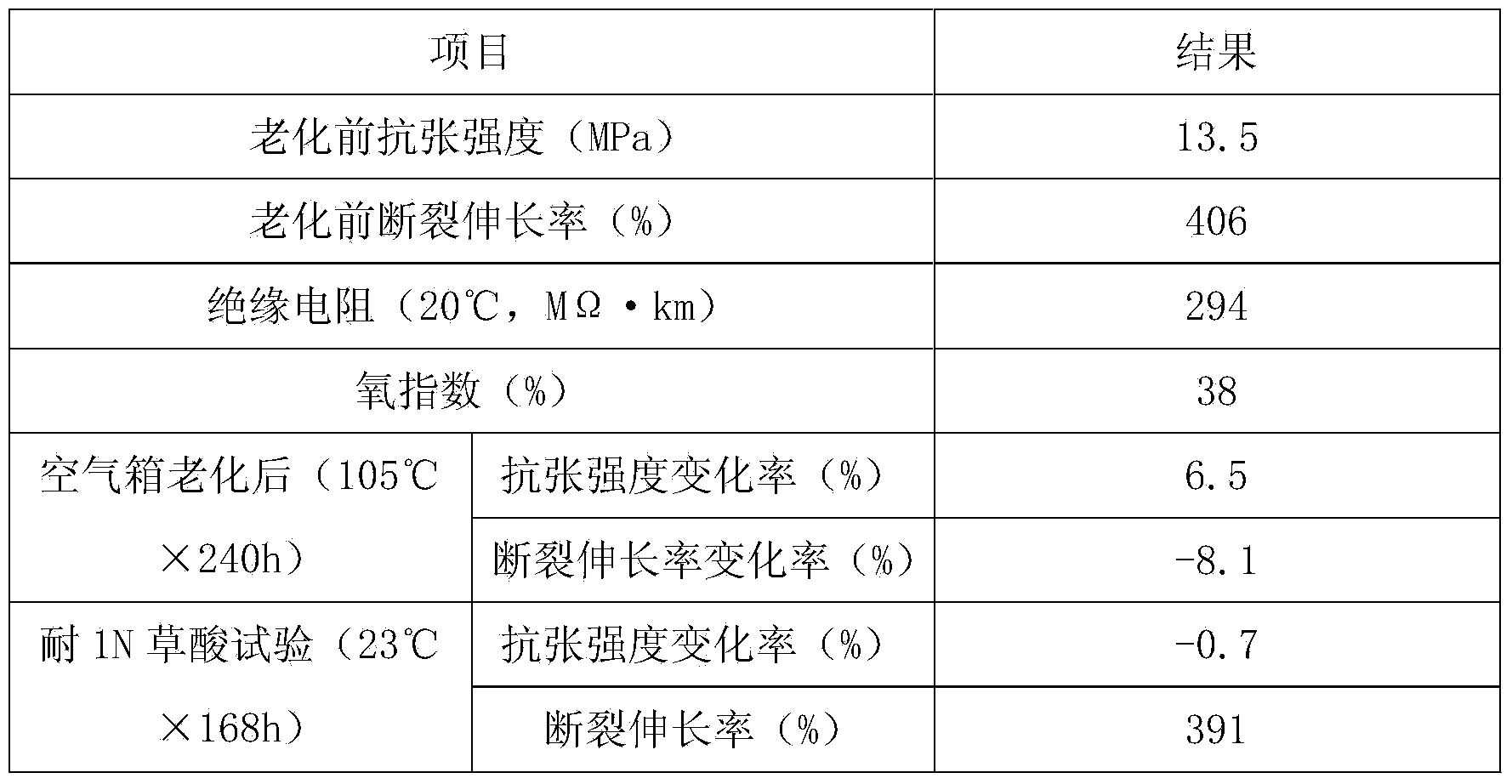

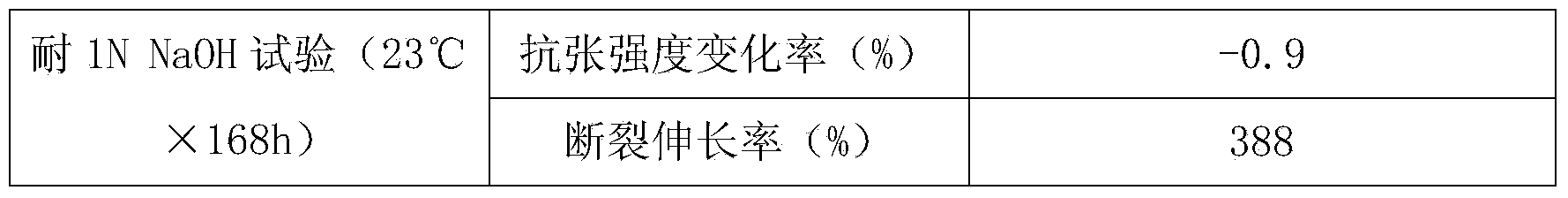

[0012] A high weather-resistant cable material for railway passenger cars, made of the following raw materials in parts by weight: EPDM rubber 60, epichlorohydrin rubber 40, polypropylene 25, trifluoropropyl methyl silicone oil 8, dicyclopentadiene petroleum Resin 10, insoluble sulfur 3, N,N'-m-phenylene bismaleimide 2, magnesium methacrylate 2.5, zinc oxide 1.5, low molecular weight polybutadiene 5, titanium dioxide 7, nano xonotlite 12. Cashew nut shell liquid 8, quick press carbon black N55025, o-diallyl bisphenol A6, N,N'-di(β-naphthyl)-p-phenylenediamine 2.5, cadmium diethyldithiocarbamate 2. Zinc hydroxystannate 2, ammonium octamolybdate 16, modified stone powder 18;

[0013] The preparation method of the modified stone powder is as follows: (1) Weigh coke gemstones, volcanic stones, and attapulgite at a weight ratio of 7:5:3, mix them uniformly, calcinate at 780°C for 1.5h, cool naturally to room temperature, pulverize, pass Sieve, stand-by; (2) get the solid content t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com