Preparation method of high-tenacity and tear-resistant ternary hydrogel based on synergetic enhancement of one-dimensional and two-dimensional nano-materials

A two-dimensional nanomaterial and nanomaterial technology, applied in the field of preparation of high toughness, tear-resistant ternary hydrogel, to achieve the effect of enhanced mechanical strength, good mechanical properties, and excellent tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

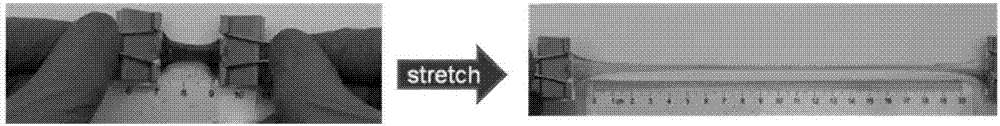

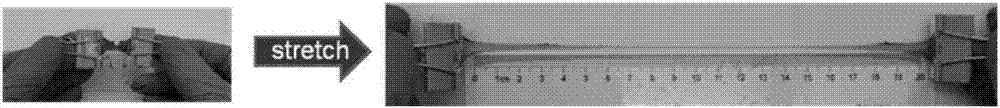

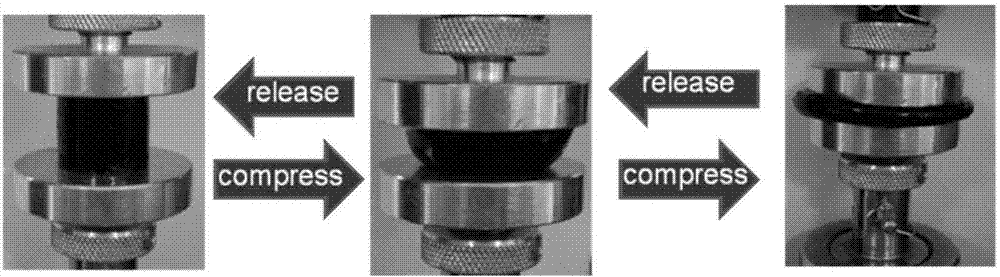

Image

Examples

Embodiment 1

[0026] 1. Prepare 2 mL of graphene oxide dispersion with a concentration of 0.8 mg / mL and 1 mL of xonotlite nanowire dispersion with a concentration of 16 mg / mL, and then add the two nanomaterial dispersions to 2 mL of deionized water in sequence, Stir magnetically for 10 minutes to obtain a uniform dispersion of nanomaterials.

[0027] 2. Place the nanomaterial dispersion obtained in step 1 in an ice-water bath, weigh 20% of the mass of the nanomaterial dispersion, and add acrylamide, a hydrophilic monomer, into the nanomaterial dispersion, stir to dissolve, and then add the nanomaterial to disperse The initiator ammonium persulfate with a liquid mass of 0.52% was added to the nanomaterial dispersion liquid, and the whole process was completed under nitrogen protection, and the nitrogen flow rate was controlled at 0.6mL / s. After stirring and dissolving, the obtained mixed solution was placed in a vacuum desiccator to remove dissolved oxygen in the mixed solution.

[0028] 3....

Embodiment 2

[0030] 1. Prepare 2 mL of a graphene oxide dispersion with a concentration of 0.8 mg / mL, then add the nanomaterial dispersion to 3 mL of deionized water, and stir magnetically for 10 minutes to obtain a uniform nanomaterial dispersion.

[0031] 2. Place the dispersion obtained in step 1 in an ice-water bath, weigh 20% of the mass of the nanomaterial dispersion, and add acrylamide, a hydrophilic monomer, into the nanomaterial dispersion, stir to dissolve, and then add the mass of the nanomaterial dispersion 0.52% of the initiator ammonium persulfate was added to the dispersion, and the whole process was completed under nitrogen protection, and the nitrogen flow rate was controlled at 0.6mL / s. After stirring and dissolving, the obtained mixed solution was placed in a vacuum desiccator to remove dissolved oxygen in the mixed solution.

[0032] 3. Transfer the mixed solution obtained in step 2 to a 60°C oven for polymerization for 10.5 hours to obtain a binary nano-hydrogel.

Embodiment 3

[0034] 1. Prepare 1 mL of xonotlite nanowire dispersion with a concentration of 16 mg / mL, then add this nanomaterial dispersion into 4 mL of deionized water, and stir magnetically for 10 minutes to obtain a uniform nanomaterial dispersion.

[0035] 2. Place the nanomaterial dispersion obtained in step 1 in an ice-water bath, weigh 20% of the mass of the nanomaterial dispersion, and add acrylamide, a hydrophilic monomer, into the nanomaterial dispersion, stir to dissolve, and then add the nanomaterial to disperse The initiator ammonium persulfate with a liquid mass of 0.52% was added to the nanomaterial dispersion liquid, and the whole process was completed under nitrogen protection, and the nitrogen flow rate was controlled at 0.6mL / s. After stirring and dissolving, the obtained mixed solution was placed in a vacuum desiccator to remove dissolved oxygen in the mixed solution.

[0036] 3. Transfer the mixed solution obtained in step 2 to a 60°C oven for polymerization for 10.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com