High-temperature special oil well cement material and preparation method thereof

A kind of oil well cement, special technology, applied in the direction of chemical instruments and methods, drilling composition, etc., can solve the problems of unavailable basic raw materials, high import price, low strength performance, etc., to achieve thickening performance and slurry stability Good sex, prolonged hydration age, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, the preparation of high temperature special oil well cement material

[0024] The high-temperature special oil well cement material of the invention is mainly used in oil and gas well workover projects with a bottom hole temperature of 60°C-130°C.

[0025] (1). Selection of raw materials

[0026] The high-temperature special oil well cement material has a wide applicable temperature range, with the highest operating temperature as high as 130°C and the lowest operating temperature as 60°C. Therefore, the present invention proposes that the raw materials for preparing this type of cement material should have better temperature stability.

[0027] There are three Portland cements specified in the national standard for the preparation of high-temperature special oil well cement materials, which are medium resistance G grade oil well cement, high resistance D grade oil well cement and high belite cement (code B). The chemical composition and mineral compositi...

Embodiment 2

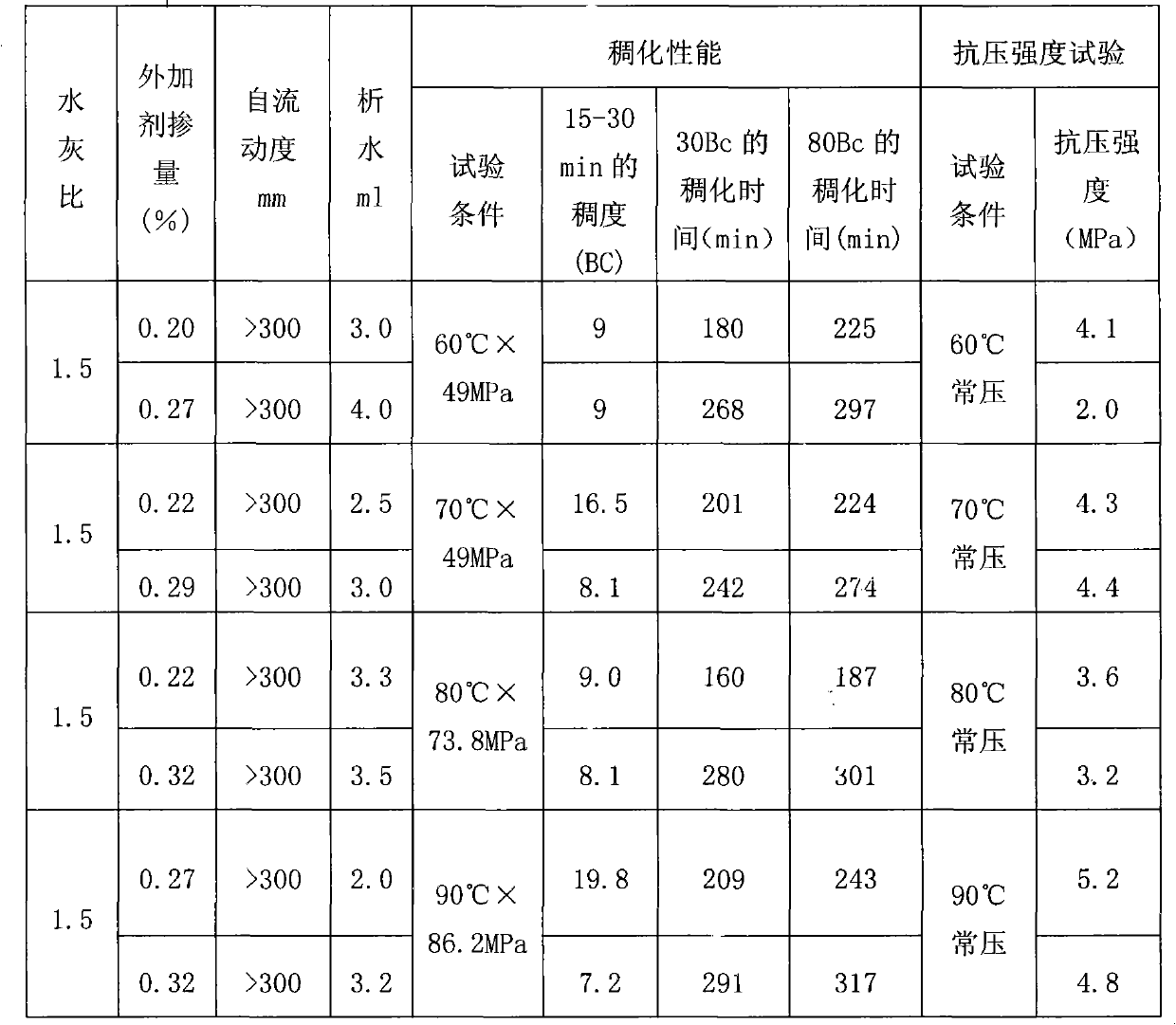

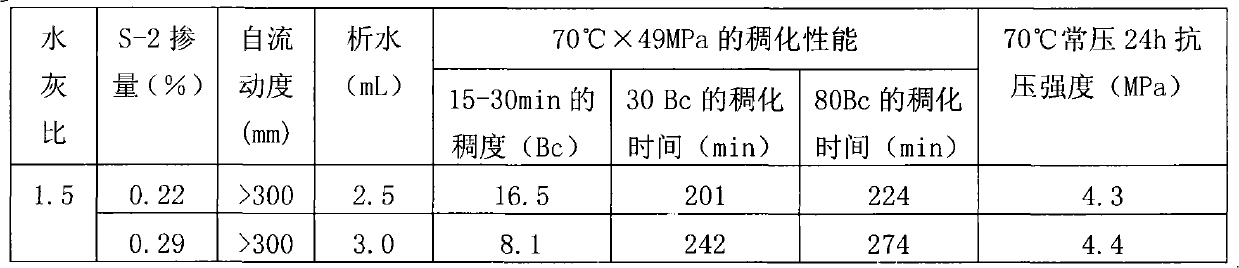

[0073] Embodiment 2, preparation of high temperature special oil well cement material

[0074] 1. Preparation process

[0075] Choose high belite cement, SiO 2 Quartz sand with a content ≥ 98% and additives S-2 and S-3 are used as raw materials for high-temperature special oil well cement materials. First, grind the high belite cement and quartz sand in a jet mill to a fine powder with a particle size ≤ 15 μm, then add the calculated amount of admixture S-2 or S-3, and then follow the method determined in Example 1 The ratio is poured into a DXH-cantilever double-helix cone mixer and mixed for 10-20 minutes to obtain a high-temperature special oil well cement material; put it into a packaging bag, and the net weight of each bag is 40kg±1kg.

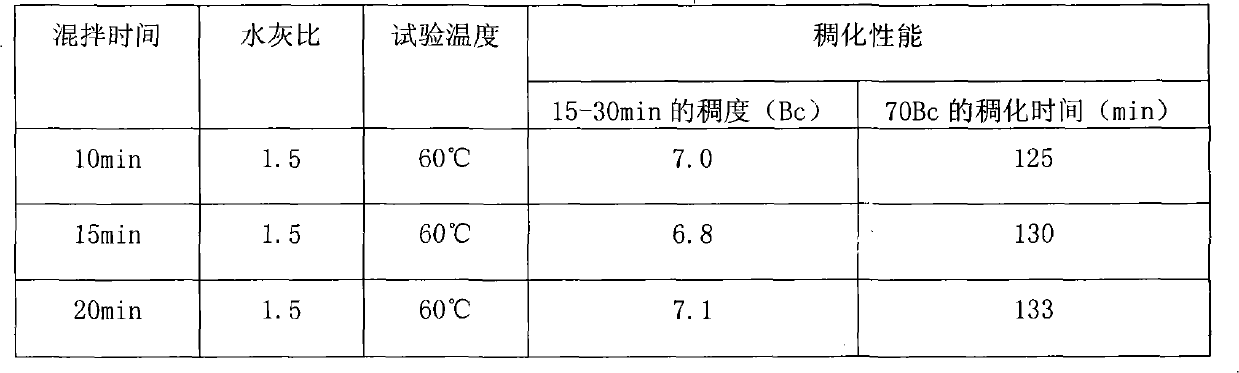

[0076] 2. Determination of mixing time

[0077] Prepare 500kg of high-temperature special oil well cement materials according to the ratio and mix them in the mixer for 10min, 15min and 20min respectively. Take an equal amount of samp...

Embodiment 3

[0101] Embodiment 3, the performance of high temperature special oil well cement material

[0102] 1. Compressive strength of high-temperature special oil well cement materials at different ages

[0103] In order to further study the strength development of high-temperature special oil well cement materials under the condition of prolonged curing time, four conditions of 60°C, 90°C normal pressure and 100°C, 130°C 20.7MPa were selected for 24h, 48h and 72h, and the test compression Variations in intensity.

[0104] The results are shown in Table 17. Under the four temperature conditions, the compressive strength of the cement increases steadily with the extension of the curing time, and no shrinkage occurs. Therefore, it makes up for the decrease in cement strength due to the addition of admixtures.

[0105] Table 17 Compressive strength results of high temperature special oil well cement materials at different ages (w / c=1.5)

[0106]

[0107] 2. Performance of high-temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com