Nano thermal insulation material and preparing method thereof

A thermal insulation material and nano thermal insulation technology, applied in the field of thermal insulation materials, can solve the problems of limited performance of a single aerogel, limited promotion and application, low inherent strength, etc. range, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

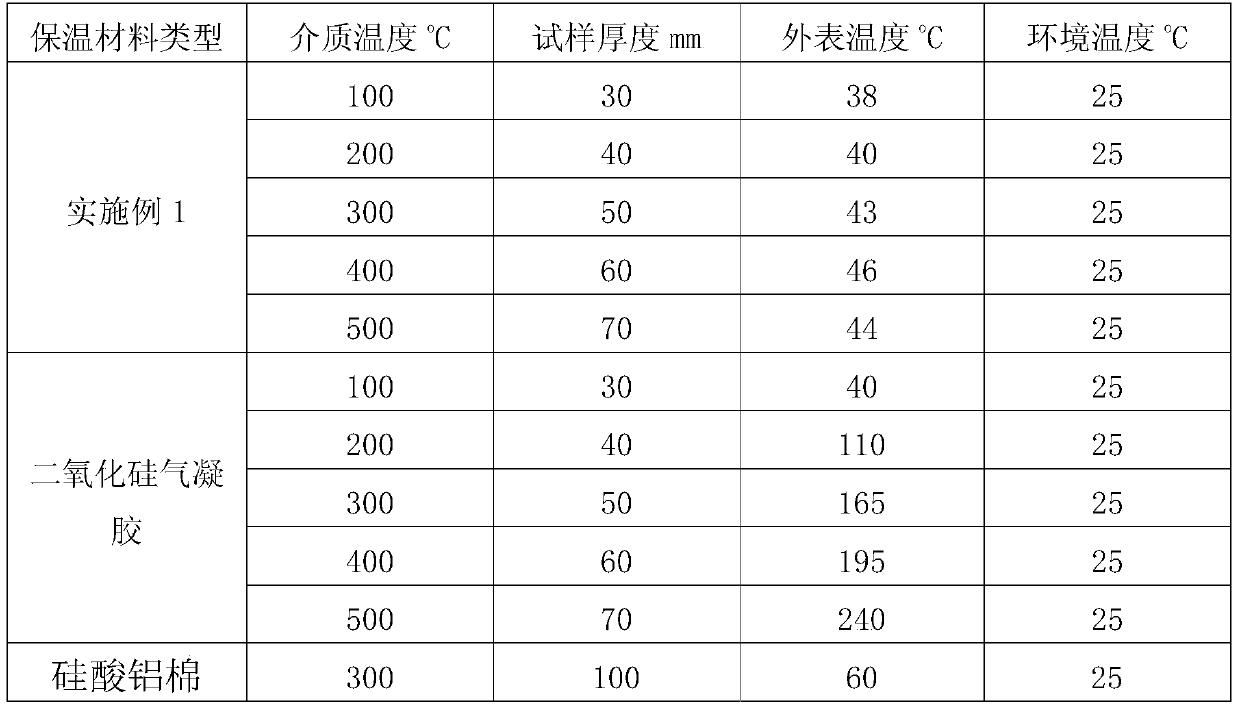

Examples

Embodiment 1

[0026] A nano heat insulation material, which is made of the following components in proportion by weight: 65 parts of titanium dioxide / silicon dioxide binary airgel, 3 parts of nano aluminum hydroxide, 1.5 parts of xonotlite, modified poly 3 parts of acrylic fiber, 6 parts of silicon carbide, 0.7 parts of anhydrous calcium chloride, 3 parts of polyvinyl alcohol, 12 parts of glass hollow microspheres, 13 parts of zirconia hollow microspheres, 4 parts of polyethylene glycol, 7 parts of perlite , 4 parts of silica fume, 2 parts of magnesium hydroxide, 0.5 part of aluminum powder, and 0.2 part of sodium methyl silicate.

[0027] Wherein, the average particle diameter of the titanium dioxide / silica binary airgel is 20nm, the specific surface area is 250±50㎡ / g, the compacted density is 80g±10 / l, and the molar ratio of titanium dioxide to silicon dioxide is 1:1;

[0028] The particle size of the nano aluminum hydroxide is 70nm; the particle size of the xonotlite is 25 μm; the diame...

Embodiment 2

[0038] A nano heat insulation material, which is made of the following components by weight: 60 parts of titanium dioxide / silicon dioxide binary airgel, 2 parts of nano aluminum hydroxide, 1 part of xonotlite, modified polymer 2 parts of acrylic fiber, 5 parts of silicon carbide, 0.6 parts of anhydrous calcium chloride, 2 parts of polyvinyl alcohol, 10 parts of glass hollow microspheres, 10 parts of zirconia hollow microspheres, 3 parts of polyethylene glycol, 6 parts of perlite , 2 parts of silica fume, 1 part of magnesium hydroxide, 0.4 part of aluminum powder, and 0.1 part of sodium methyl silicate.

[0039] Wherein, the average particle diameter of the titanium dioxide / silica binary airgel is 20nm, the specific surface area is 250±50㎡ / g, the compacted density is 80g±10 / l, and the molar ratio of titanium dioxide to silicon dioxide is 1:1;

[0040] The particle size of the nano aluminum hydroxide is 60nm; the particle size of the xonotlite is 25 μm; the diameter of the modi...

Embodiment 3

[0050] A nano heat insulation material, which is made of the following components by weight: 70 parts of titanium dioxide / silicon dioxide binary airgel, 4 parts of nano aluminum hydroxide, 2 parts of xonotlite, modified polymer 4 parts of acrylic fiber, 7 parts of silicon carbide, 0.8 parts of anhydrous calcium chloride, 4 parts of polyvinyl alcohol, 15 parts of glass hollow microspheres, 15 parts of zirconia hollow microspheres, 5 parts of polyethylene glycol, and 8 parts of perlite , 6 parts of silica fume, 3 parts of magnesium hydroxide, 0.6 parts of aluminum powder, and 0.3 parts of sodium methyl silicate.

[0051] Wherein, the average particle diameter of the titanium dioxide / silica binary airgel is 20nm, the specific surface area is 250±50㎡ / g, the compacted density is 80g±10 / l, and the molar ratio of titanium dioxide to silicon dioxide is 1:1;

[0052] The particle size of the nano aluminum hydroxide is 80nm; the particle size of the xonotlite is 25 μm; the diameter of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com