Method for synthesizing calcium silicate by utilizing soda-lime sintering process red mud alkaline method

A sintering method, calcium silicate technology, applied in the direction of alkaline earth metal silicate, silicate, etc., can solve the problems of large amount of red mud, difficult treatment, heavy pollution, etc., to achieve low equipment requirements, high production efficiency, no Effects of waste and pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] S1. Preparation of raw material slurry: mix soda lime sintering red mud with sodium silicate solution, stir evenly to prepare raw material slurry, wherein, in the mixed raw material slurry, the calcium-silicon molar ratio Ca / Si is 0.83:1, and the raw material The liquid-solid ratio L / S in the slurry is 20:1;

[0026] S2. Preparation of calcium silicate material slurry by hydrothermal synthesis: put the raw material slurry in a closed reaction kettle, and place it in an oil bath at 180°C for 8 hours (heat for 8 hours after the temperature of the oil bath reaches 180°C). Stir at a speed of 300r / min during the heating process, and the hydrothermal reaction makes it generate tobermorite slurry;

[0027] Here, the purpose of using a closed reactor to contain the raw material slurry is mainly to provide a closed reaction condition, and of course other closed measures can also be taken.

[0028] The oil bath heating method can be replaced by salt bath heating or electric heat...

Embodiment 2-10

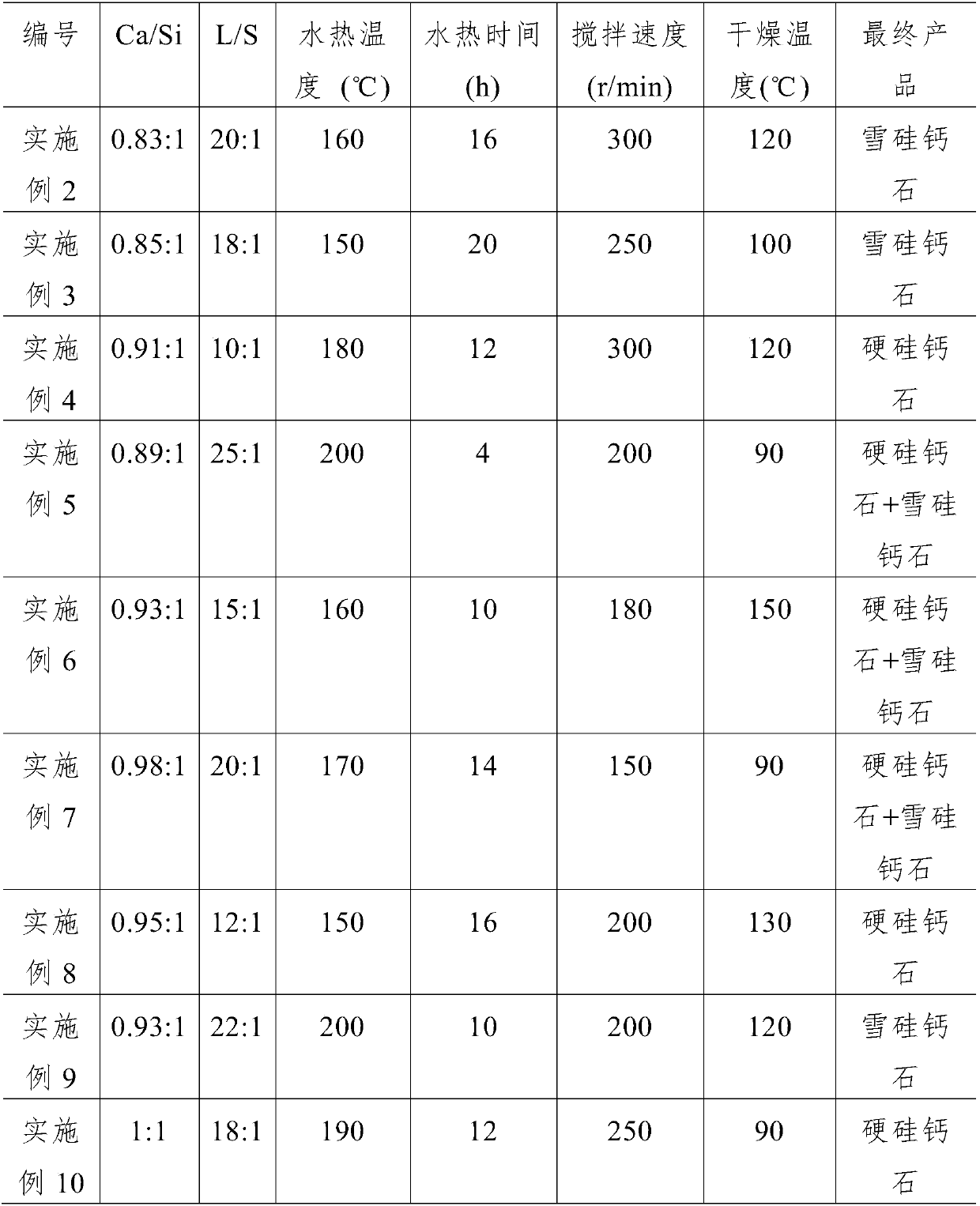

[0033] Similar to the synthesis steps of Example 1, Example 2-10 is by adjusting the calcium-silicon molar ratio and the liquid-solid ratio L / S in the step S1 of the synthesis process, the hydrothermal temperature, the hydrothermal time and the stirring speed in the step S2, Different calcium silicate materials are synthesized under parameter conditions such as drying temperature in step S3. Examples 2-10 are specifically shown in Table 1 for the synthesis of different calcium silicate materials.

[0034] Synthesis of different calcium silicate materials in Examples 2-10 of Table 1.

[0035]

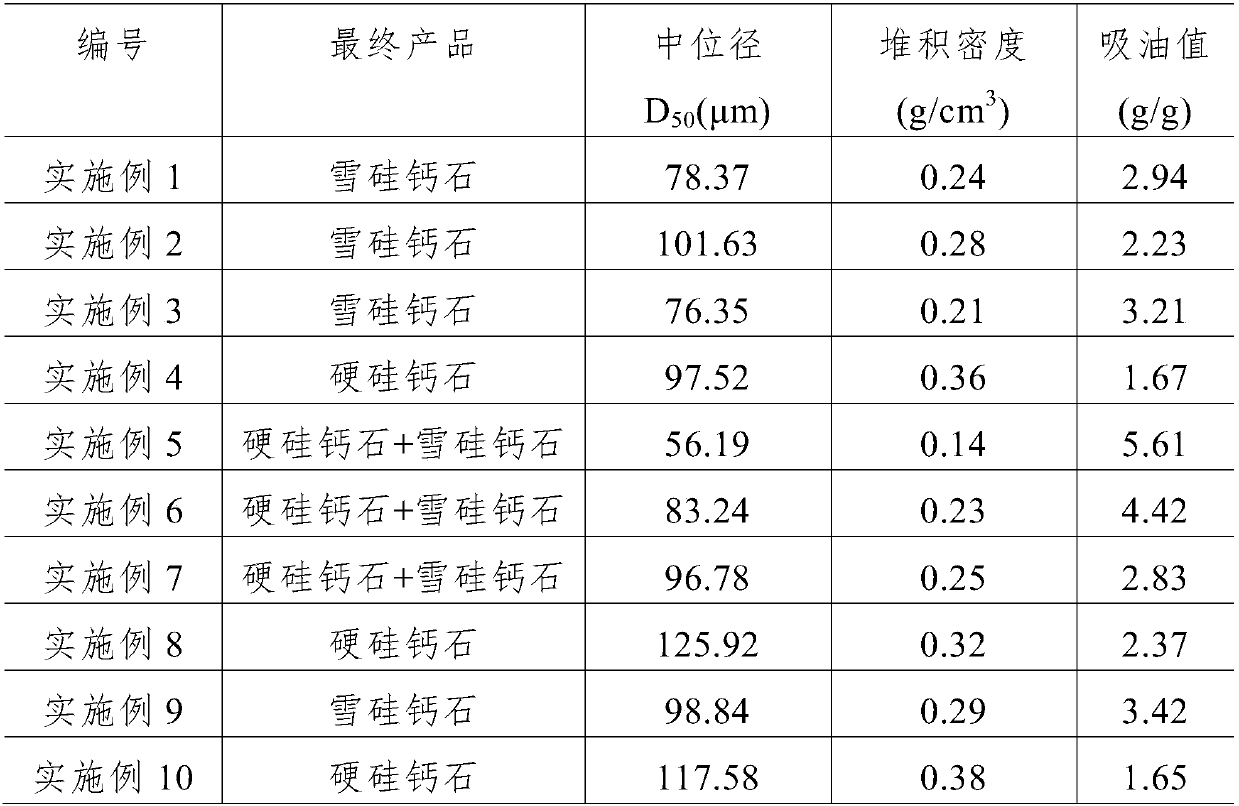

[0036] It can be seen from Table 1 that calcium silicate products with different crystal forms and physical and chemical properties can be obtained by adjusting the parameters such as silicon-calcium molar ratio, liquid-solid ratio, hydrothermal reaction temperature, hydrothermal reaction time, and stirring speed during the synthesis process. . Specifically, when the silicon-calcium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com