Preparation method for cement-based crack grouting material for road bridges

A bridge-based, cement-based technology, applied in the field of grouting, can solve problems such as poor strength performance and application limitations, and achieve the effects of improving compressive strength, good process performance, and enhancing interface bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment relates to a cement-based crack grout for road bridges, which is composed of the following raw materials in parts by weight:

[0041] 76 parts of composite cement;

[0042] 7 parts of compound emulsion;

[0043] 10 parts of pearlite;

[0044] Halloysite clay 8 parts;

[0045] 4 parts meerschaum;

[0046] 3 parts of epichlorohydrin graft copolymerization modified bone glue;

[0047]xonotlite 6 parts;

[0048] 1 part of composite water repellent;

[0049] 2 parts of composite coupling agent;

[0050] 3 parts compound rubber powder;

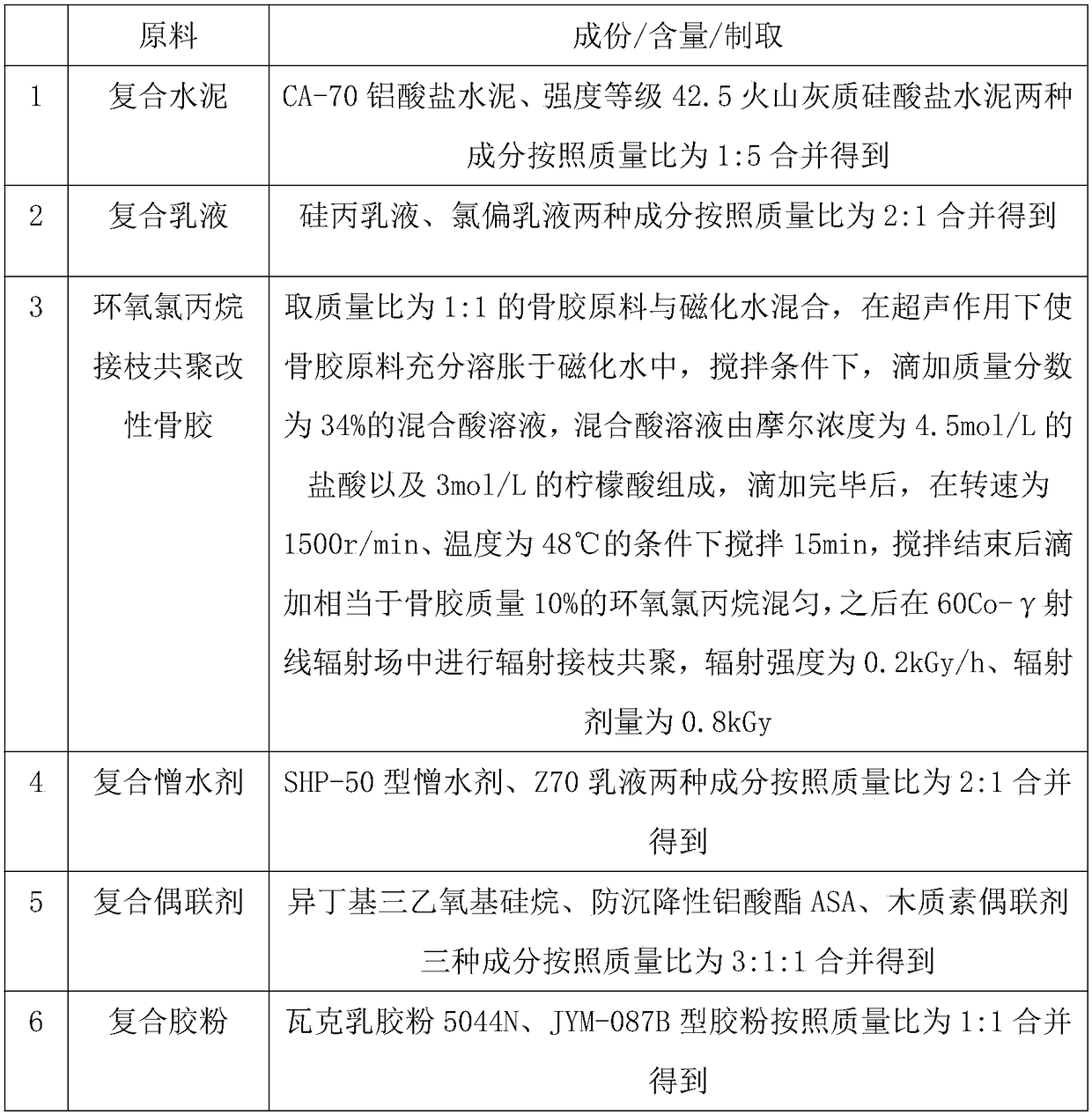

[0051] The selection and preparation of composite cement, composite emulsion, epichlorohydrin graft copolymerized modified bone glue, composite hydrophobic agent, composite coupling agent and composite rubber powder in this embodiment are shown in Table 1 below:

[0052] Table 1

[0053]

[0054] The preparation method of the crack grouting material in this embodiment is generally carried out according to the follo...

Embodiment 2

[0059] This embodiment relates to a cement-based crack grout for road bridges, which is composed of the following raw materials in parts by weight:

[0060] 84 parts of composite cement;

[0061] 8 parts of compound emulsion;

[0062] 12 parts of pearl sand;

[0063] Halloysite clay 10 parts;

[0064] 5 parts meerschaum;

[0065] 4 parts of epichlorohydrin graft copolymerization modified bone glue;

[0066] xonotlite 8 parts;

[0067] 1.5 parts of composite water repellent;

[0068] 2.5 parts of composite coupling agent;

[0069] 4 parts compound rubber powder;

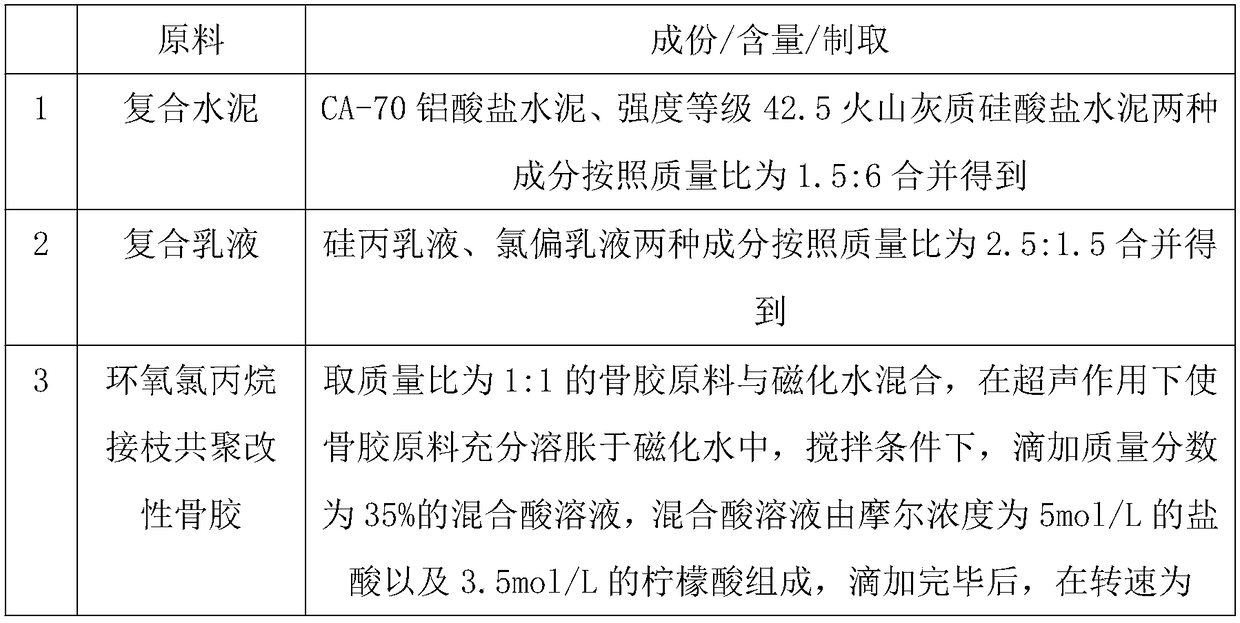

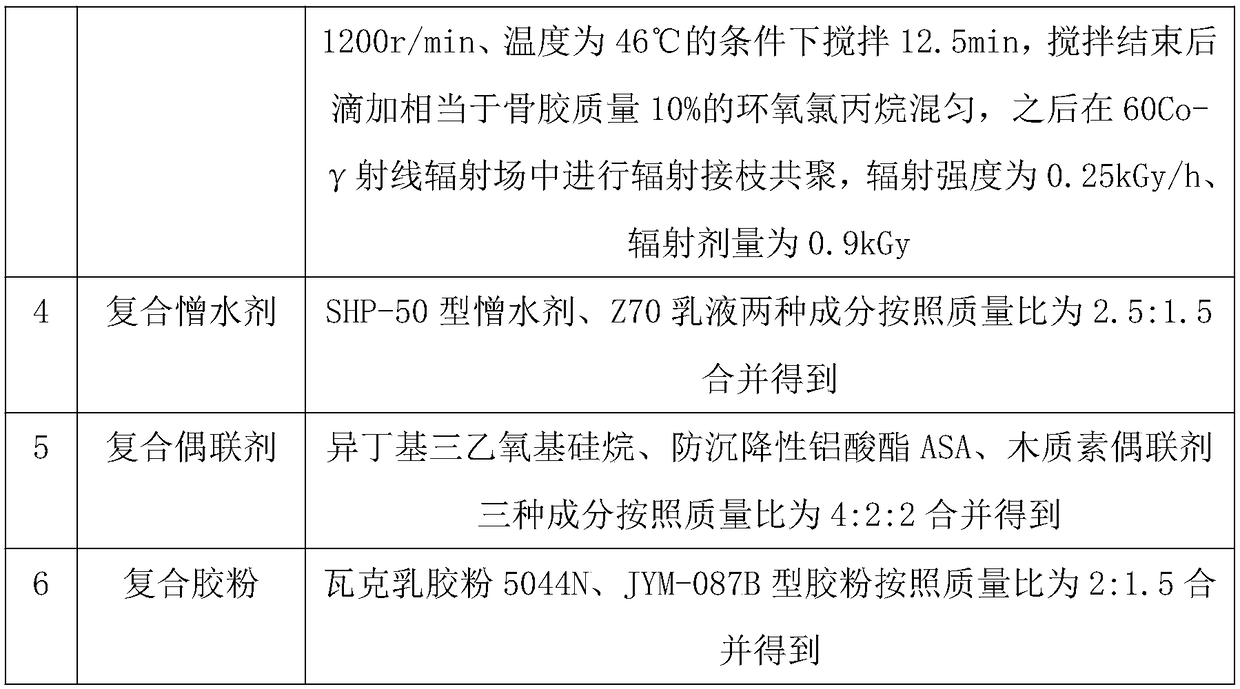

[0070] The selection and preparation of composite cement, composite emulsion, epichlorohydrin graft copolymerized modified bone glue, composite hydrophobic agent, composite coupling agent and composite rubber powder in this embodiment are shown in Table 2 below:

[0071] Table 2

[0072]

[0073]

[0074] The preparation method of the crack grouting material in this embodiment is generally carried out a...

Embodiment 3

[0079] This embodiment relates to a cement-based crack grout for road bridges, which is composed of the following raw materials in parts by weight:

[0080] 92 parts of composite cement;

[0081] 9 parts of compound emulsion;

[0082] 15 parts of pearl sand;

[0083] Halloysite clay 12 parts;

[0084] 6 parts meerschaum;

[0085] 5 parts of epichlorohydrin graft copolymerization modified bone glue;

[0086] 10 parts of xonotlite;

[0087] 2 parts of composite water repellent;

[0088] 3 parts of composite coupling agent;

[0089] 5 parts of compound rubber powder;

[0090] The selection and preparation of composite cement, composite emulsion, epichlorohydrin graft copolymerized modified bone glue, composite water-repellent agent, composite coupling agent and composite rubber powder in this embodiment are shown in Table 3 below:

[0091] table 3

[0092]

[0093] The preparation method of the crack grouting material in this embodiment is generally carried out accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com