A kind of discoloration gypsum board and preparation method thereof

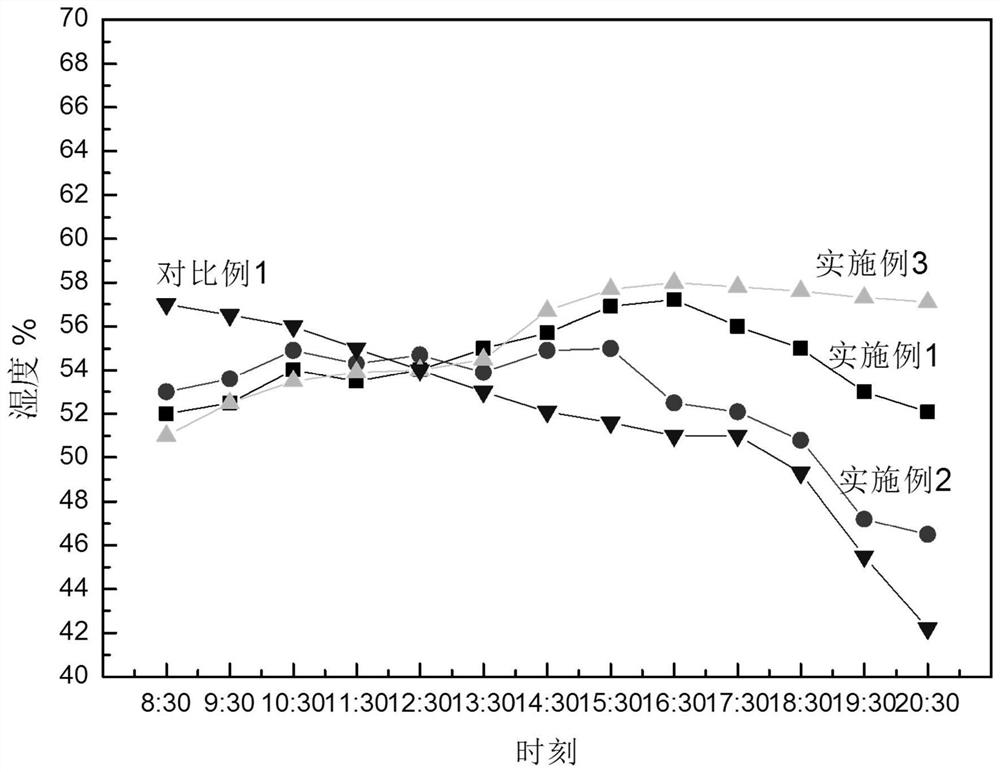

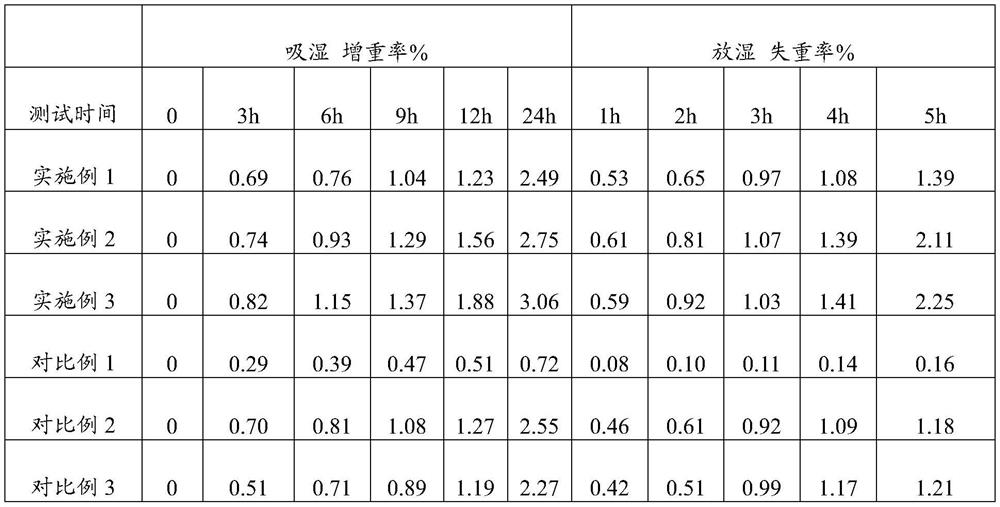

A technology of gypsum board and gypsum powder, which is applied in the field of building materials, can solve the problems of limited adjustment range and less research, and achieve the effect of overcoming single pattern, improving moisture absorption and moisture release performance, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Pass 1000 grams of gypsum powder through an 80-mesh sieve, and crush and grind 50 g of discolored silica gel to 80 mesh. Mix the treated gypsum powder, discolored silica gel powder and 3g of water reducer (BASF Melflux5691F) evenly;

[0057] (2) Test steps (1) Standard consistency expansion degree of mixed powder to determine the standard consistency water consumption of mixed powder.

[0058] (3) According to the water consumption of the standard consistency, take the mixing water, mix the mixing water with the mixing powder, foaming agent (0.35g, SASN812) to prepare slurry.

[0059] (4) The prepared slurry is placed in the mold, and the thickness of the plate is 9.5 mm. After the final setting is completed, the board is placed in an oven and dried at 45°C until constant weight.

Embodiment 2

[0061] (1) Pass 600 grams of gypsum powder through an 80-mesh sieve; mix the treated gypsum powder with 1 g of water reducer (BASF Melflux5691F) evenly. (2) Test the expansion degree of the mixed powder to determine the water consumption of the standard consistency of the mixed powder.

[0062] (3) Pass 400 grams of gypsum powder through an 80-mesh sieve. Pass 600 grams of gypsum powder through an 80-mesh sieve, crush and grind 50 g of discolored silica gel to 80 mesh; mix the treated gypsum powder, discolored silica gel powder and 2 g of water reducer (BASF Melflux5691F) evenly.

[0063] (4) Test the expansion degree of the mixed powder obtained in step (3) to determine the standard consistency water consumption of the mixed powder.

[0064] (5) Measure the standard consistency water consumption by step (2), take the mixing water, mix the mixing powder and foaming agent (0.15g, SASN812) to prepare slurry 1.

[0065] (6) placing the slurry 1 prepared in step (5) into a mol...

Embodiment 3

[0070] The difference between Example 3 and Example 2 is that the color-changing silica gel material in the gypsum board raw material is ground to 600 mesh, and the other raw materials and preparation steps are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com