Process for manufacturing xonotlite type calcium silicate heat insulation material

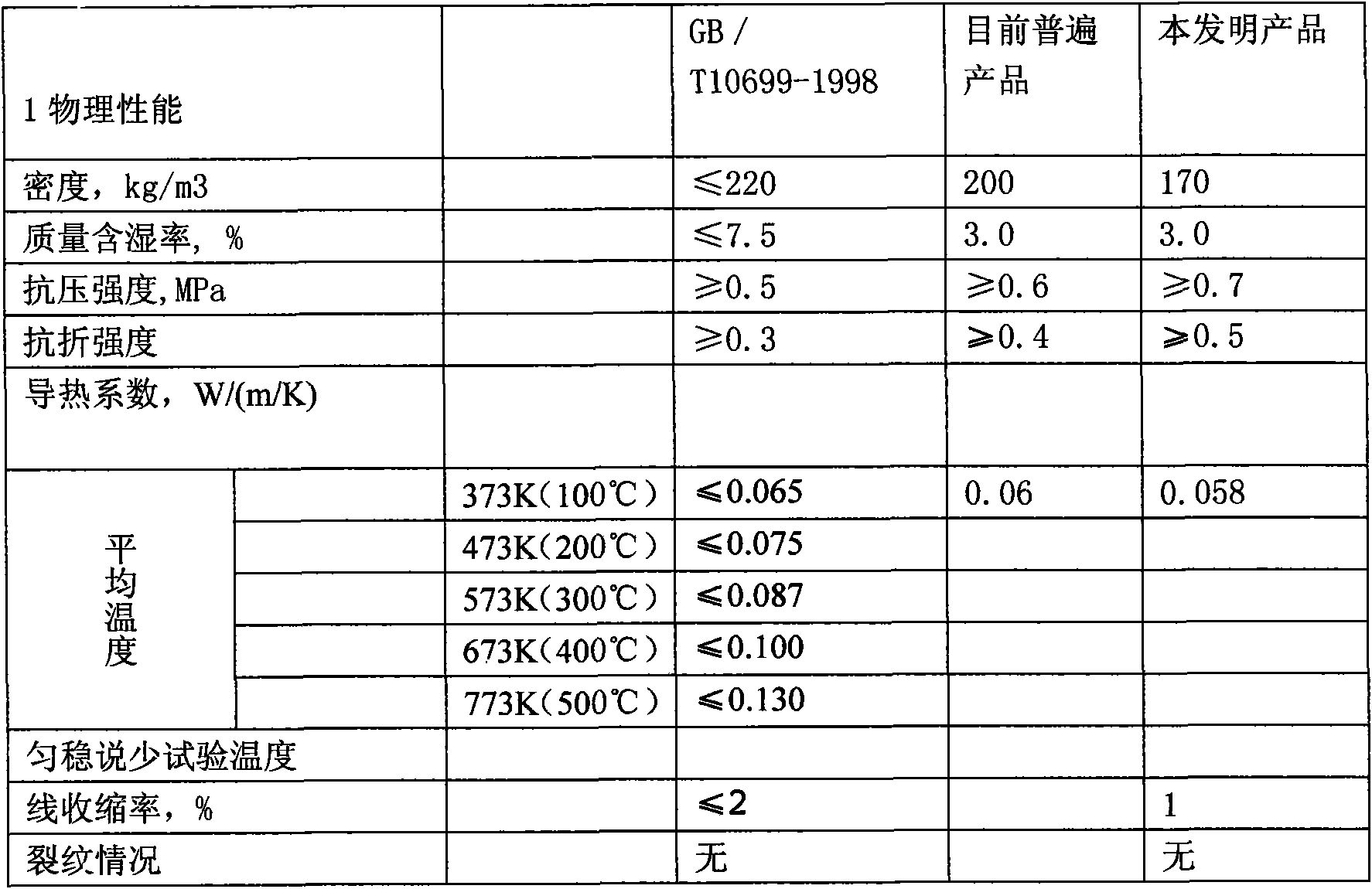

A technology of thermal insulation materials and process methods, applied in the field of manufacturing xonotlite type calcium silicate thermal insulation materials, which can solve the problems of low utilization rate of raw materials, unstable product quality, and inability to change the speed of rotation, etc., to achieve small bulk density and high yield High, the effect of preventing drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] 1. Formula. Silicon dioxide 2.56%, calcium hydroxide 3.06%, silica sol 0.06%, wollastonite 0.42%, cotton fiber 0.2%, glass fiber 0.2%, water 93.5%.

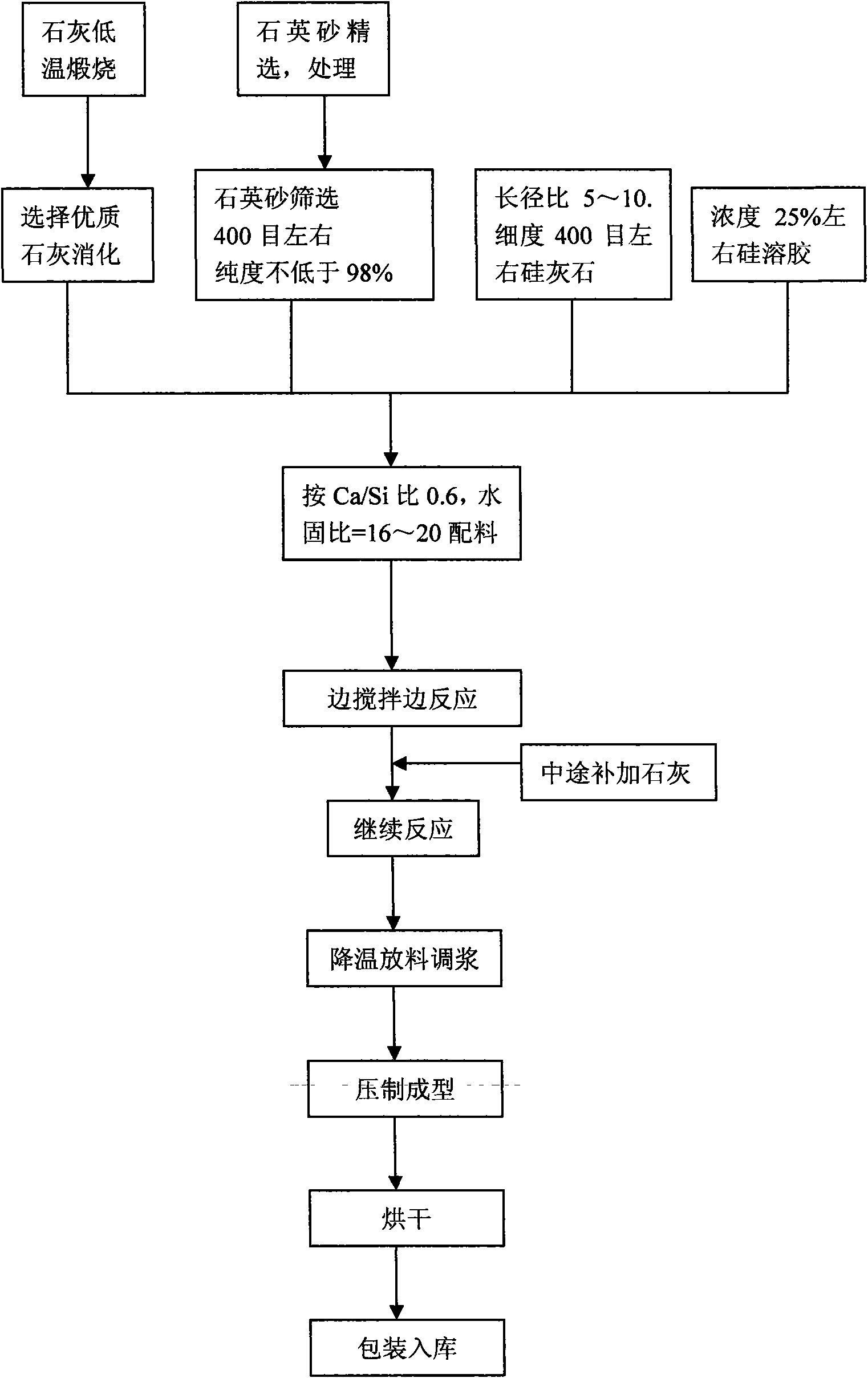

[0030] 2. Manufacturing steps:

[0031] The first step: raw material selection. Choose high-quality limestone, calcinate at 900°C, and digest under strong stirring. The water temperature should be above 80°C, and the water volume should be 10 times. Choose quartz sand and other auxiliary materials with a silica content ≥ 98% and a particle size of about 400 mesh.

[0032] Step Two: Toppings. According to Ca / Si molar ratio=0.55, water-solid ratio=16~20 batching. Calcium hydroxide 1.68%, silicon dioxide 2.56%, silica sol 0.06, wollastonite 0.42% ingredients, water 78%. Stir and mix evenly and pour into the dynamic reaction kettle.

[0033] The third step: slurry pre-reaction. Steam heating, the temperature is raised to 215°C within one and a half hours, and kept for 1 hour. Then the temperature was raised to 225° C.,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com