High-fracture-toughness microcrystalline glass for mobile phone backboard and preparation method of high-fracture-toughness microcrystalline glass

A glass-ceramic and high-fracture technology, which is applied in the field of high-fracture-toughness glass-ceramic for mobile phone backplanes and its preparation, can solve the problem that glass-ceramic cannot have both fracture toughness and chemical strengthening, and meets the requirements of chemical strengthening. , Improve the anti-drop performance and highlight the effect of fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

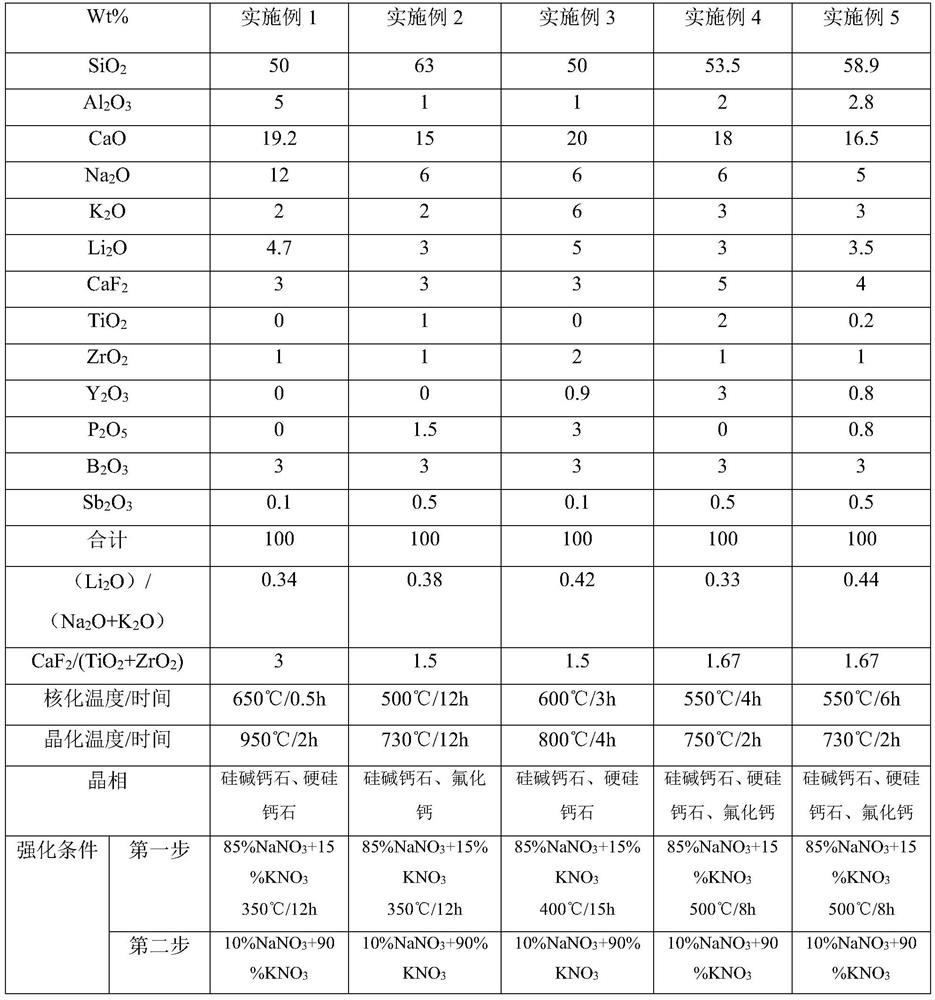

Embodiment 1

[0048]S1, weigh the raw material as various components, select the corresponding oxide, hydroxide, carbonate, nitrate, fluoride, chloride, hydroxide, and spermatic compounds, etc., according to the following weight percentage: 50% SIO25% Al2O319.2% CaO, 12% NA2O, 2% K2O, 4.7% li2O, 3% CAF21% Zro23% B2O30.1% SB2O3Preparation of basic glass, 1350 ° C for 12 hours; (Lii);2O) / (NA2O + K2O) = 0.34, CAF2 / (Tio2+ Zro2) = 3;

[0049]S2, forming, annealing, cold processing;

[0050]S3, low temperature verification, high temperature crystallization, low temperature detection temperature is 650 ° C, the holding time is 0.5 h, the high temperature crystallization temperature is 950 ° C, the holding time is 0.5 h;

[0051]S4, two-step chemistry strengthening: first 85% nano3+ 15% KNO3350 ° C in a composite melting salt for 12 h, then 10% nano3+ 90% KNO3The composite melting salt was soaked in 480 ° C for 0.5 h.

Embodiment 2

[0053]S1, weigh the raw material as various components, select the corresponding oxide, hydroxide, carbonate, nitrate, fluoride, chloride, hydroxide, and spermatic compounds, etc., according to the following weight percentage: 63% SiO21% Al2O315% CaO, 6% NA2O, 2% K2O, 3% li2O, 3% CAF21% Zro23% B2O31% TIO20.5% SB2O3, 1.5% P2O5Preparation of base glass, 1450 ° C for 6 hours, molten; "where (Lii2O) / (NA2O + K2O) = 0.38, CAF2 / (Tio2+ Zro2) = 1.5;

[0054]S2, forming, annealing, cold processing;

[0055]S3, low temperature nucleation, high temperature crystallization, low temperature calibration temperature of 500 ° C, the holding time is 12 h, the high temperature crystallization temperature is 730 ° C, the holding time is 12 h;

[0056]S4, two-step chemistry strengthening: first 85% nano3+ 15% KNO3350 ° C in a composite melting salt for 12 h, then 10% nano3+ 90% KNO3The composite melting salt was soaked in 480 ° C for 0.5 h.

Embodiment 3

[0058]S1, weigh the raw material as various components, select the corresponding oxide, hydroxide, carbonate, nitrate, fluoride, chloride, hydroxide, and spermatic compounds, etc., according to the following weight percentage: 50% SIO21% Al2O320% CaO, 6% NA2O, 6% K2O, 5% li2O, 3% CAF22% Zro23% B2O30.1% SB2O30.9% Y2O33% P2O5Preparation of basic glass, 1350 ° C for 12 hours; (Lii);2O) / (NA2O + K2O) = 0.42, CAF2 / (Tio2+ Zro2) = 1.5;

[0059]S2, forming, annealing, cold processing;

[0060]S3, low temperature nucleation, high temperature crystallization, low temperature calibration temperature of 600 ° C, the holding time is 3 h, the high temperature crystallization temperature is 800 ° C, the holding time is 4 h;

[0061]S4, two-step chemistry strengthening: first 85% nano3+ 15% KNO3400 ° C for 15 h in a composite melting salt, then 10% nano3+ 90% KNO3Soak 480 ° C in a composite melting salt for 4 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com