Method for preparing xonotlite by using silicium-calcium slag

A technology of tobermorite and calcium silicate slag, applied in the field of thermal insulation materials, can solve the problems of high production cost of tobermorite, increased cost of raw materials, long production time, etc., so as to solve storage and environmental pollution, and reduce the cost of raw materials , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

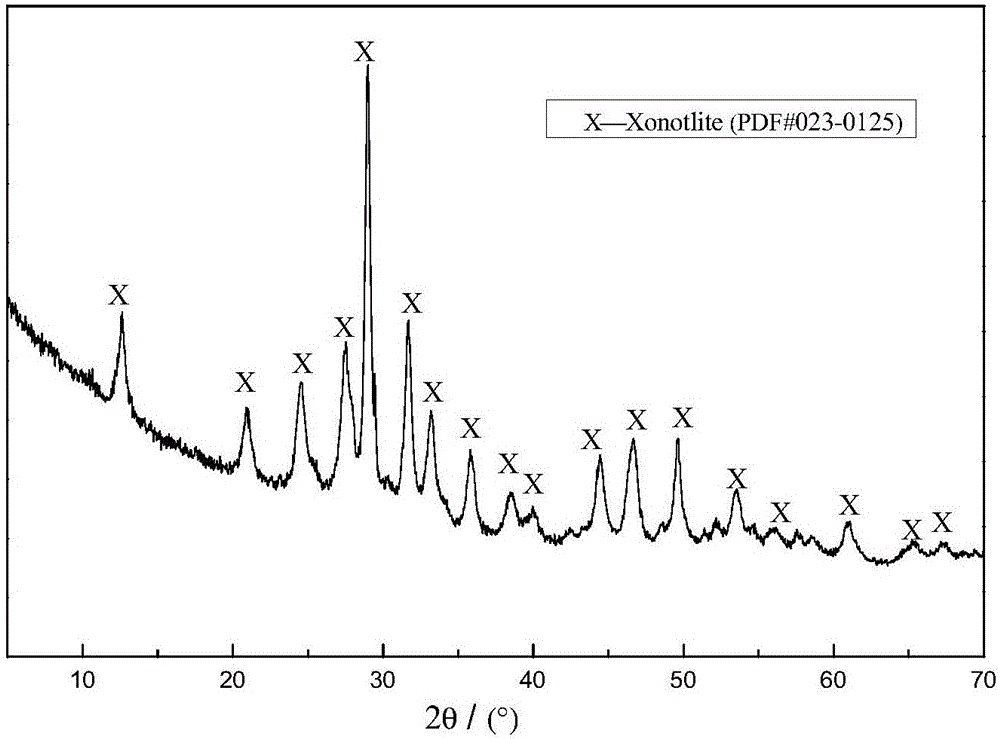

Image

Examples

Embodiment 1

[0032] The silicon-calcium slag used in this example is taken from an alumina plant in Hohhot, Inner Mongolia, which is a by-product of extracting alumina from fly ash by pre-desilication soda lime sintering method, and the quartz sand is taken from the Ordos area of Inner Mongolia. The main chemical components of Buqi Desert are shown in Table 1 and Table 2 respectively.

[0033] Table 1 Chemical composition of silicon-calcium slag

[0034] Calcium silicon slag CaO SiO 2

Al 2 o 3

Fe 2 o 3

Na 2 o

MgO content(%) 56.28 27.54 6.23 1.33 2.98 1.78

[0035] Table 2 Chemical composition of quartz sand

[0036] Quartz sand CaO SiO 2

al 2 o 3

Fe 2 o 3

Na 2 o

MgO content(%) 1.67 93.79 0.84 2.64 0.21 0.25

[0037] Get the above-mentioned 100 parts by weight of silicon-calcium slag and 36.96 parts by weight of quartz sand and mix it, use a ball mill to grind it until the p...

Embodiment 2

[0042] The silicon-calcium slag used in this example was obtained from an alumina plant in Hohhot, Inner Mongolia, and the silica fume was obtained from a metallurgical group in Ordos, Inner Mongolia. The main chemical components are shown in Table 3 and Table 4, respectively.

[0043] Table 3 Chemical composition of silicon-calcium slag

[0044] Calcium silicon slag CaO SiO 2

Al 2 o 3

Fe 2 o 3

Na 2 o

MgO content(%) 58.29 25.45 5.83 1.83 3.56 0.82

[0045] Table 4 Chemical composition of silica fume

[0046] Silica fume CaO SiO 2

Al 2 o 3

Fe 2 o 3

Na 2 o

MgO content(%) 2.78 89.27 2.98 1.64 1.57 1.25

[0047] After taking the above-mentioned 100 parts by weight of calcium silicate slag and 42.88 parts by weight of silica fume and mixing them, use a ball mill to grind them until all particle sizes are less than 0.08mm, then add 0.4 parts by weight of calcium chlorid...

Embodiment 3

[0052] The silicon-calcium slag used in this example is taken from an alumina factory in Hohhot, Inner Mongolia, and it is prepared by the method described in Example 2 of the patent CN102249253A. The chemical composition is shown in Table 5 and Table 6, respectively.

[0053] Table 5 Chemical composition of silicon-calcium slag

[0054] Calcium silicon slag CaO SiO 2

Al 2 o 3

Fe 2 o 3

Na 2 o

MgO content(%) 55.74 27.89 5.96 1.57 2.87 1.05

[0055] Table 6 Chemical composition of silica

[0056] Silica CaO SiO 2

al 2 o 3

Fe 2 o 3

Na 2 o

MgO content(%) 0.24 72.31 1.02 0.21 1.57 0.45

[0057] Take the above-mentioned 100 parts by weight of silicon-calcium slag and mix 33.35 parts by weight of white carbon black, use a ball mill to grind it until all particle sizes are less than 0.08mm, then add 0.3 parts by weight of barium chloride, 0.2 parts by weight of oxychlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com