Superfine dry powder extinguishing agent

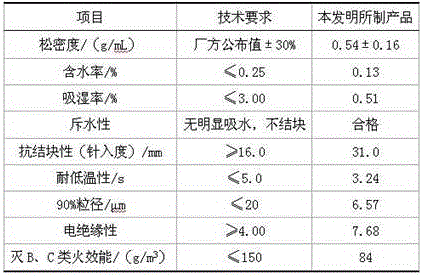

A technology of ultra-fine dry powder and fire extinguishing agent, which is used in fire protection equipment and other directions, can solve the problems of caking, easy moisture absorption of fire extinguishing agent, and failure of fire extinguishing agent, and achieves simple process, good fluidity and hydrophobicity, and anti-caking performance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 An ultrafine dry powder fire extinguishing agent is mainly prepared from the following raw materials (5 kg each): 7 parts of alkali slag, 30 parts of sodium bicarbonate, 0.5 part of talcum powder, 5 parts of marl, xonotlite 1 part, 30 parts of ammonium sulfate, 3 parts of ammonium polyphosphate, 10 parts of gypsum, 1 part of tin oxide, 2 parts of silicon nitride, 1 part of silicone oil, and 0.4 parts of polybutene.

[0024] A kind of preparation method of superfine dry powder fire extinguishing agent is:

[0025] (1) Put alkali slag, marl, xonotlite and gypsum through a 100-mesh sieve and put them into a grinder, grind for 80 minutes and then discharge;

[0026] (2) Take 40% sodium bicarbonate and 50% ammonium sulfate in parts by mass and place them in a mixing mixer, add talcum powder, ammonium polyphosphate, tin oxide, silicon nitride and the final product made in step (1), and stir After 30 minutes, add 60% sodium bicarbonate and 50% ammonium sulfate of th...

Embodiment 2

[0029] Example 2 An ultrafine dry powder fire extinguishing agent, mainly prepared from the following raw materials (5 kg each): 10 parts of alkali slag, 40 parts of sodium bicarbonate, 1 part of talcum powder, 8 parts of marl, xonotlite 3 parts, 45 parts of ammonium sulfate, 7 parts of ammonium polyphosphate, 20 parts of gypsum, 4 parts of tin oxide, 5 parts of silicon nitride, 2 parts of silicone oil, and 0.6 parts of polybutene.

[0030] A kind of preparation method of superfine dry powder fire extinguishing agent is:

[0031] (1) Put alkali slag, marl, xonotlite and gypsum through a 200-mesh sieve and put them into a grinder, grind for 160 minutes and then discharge;

[0032] (2) Take 40% by mass of sodium bicarbonate and 50% of ammonium sulfate and place them in a mixing mixer, add talcum powder, ammonium polyphosphate, tin oxide, silicon nitride and the final product made in step (1), and stir for 50 Minutes, then add 60% sodium bicarbonate and 50% ammonium sulfate of t...

Embodiment 3

[0035] Example 3 An ultra-fine dry powder fire extinguishing agent is mainly prepared from the following raw materials (5 kg each): 8 parts of alkali slag, 32 parts of sodium bicarbonate, 0.6 part of talcum powder, 6 parts of marl, xonotlite 1.5 parts, 35 parts of ammonium sulfate, 4 parts of ammonium polyphosphate, 13 parts of gypsum, 2 parts of tin oxide, 3 parts of silicon nitride, 1.2 parts of silicone oil, 0.45 parts of polybutene.

[0036] A kind of preparation method of superfine dry powder fire extinguishing agent is:

[0037] (1) Put alkali slag, marl, xonotlite and gypsum through a 120-mesh sieve and put them into a grinder, grind for 100 minutes and then discharge;

[0038] (2) Take 40% by mass of sodium bicarbonate and 50% of ammonium sulfate and place them in a mixing mixer, add talcum powder, ammonium polyphosphate, tin oxide, silicon nitride and the final product made in step (1), and stir for 35 Minutes, then add 60% sodium bicarbonate and 50% ammonium sulfate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com