Waterproof interior wall putty powder and preparation method thereof

A technology of interior wall putty powder and starch, which is applied in the direction of filling slurry, etc., can solve the problems of affecting appearance, poor water resistance, peeling, mildew, etc., and achieves the effects of scientific preparation, convenient construction and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

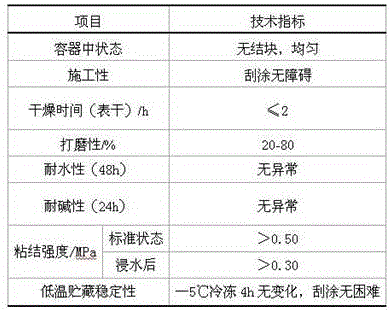

Image

Examples

Embodiment 1

[0022] Example 1 Water-resistant interior wall putty powder is mainly prepared from the following raw materials (5 kg each): 8 parts of sodium polyacrylate, 9 parts of polyvinyl acetate, 38 parts of ash calcium powder, and 15 parts of hydroxypropyl methylcellulose , 20 parts of sepiolite, 94 parts of heavy calcium carbonate, 7 parts of polyvinylidene chloride, 15 parts of soluble starch, 0.5 part of defoamer, and 0.4 part of leveling agent. The preparation method of above-mentioned water-resistant interior wall putty powder is:

[0023] (1) Take lime calcium powder, sepiolite and heavy calcium carbonate and place them in a grinder, crush and grind for 25 minutes, take them out and pass through a 300-mesh sieve to make raw material powder;

[0024] (2) Put hydroxypropyl methylcellulose and polyvinylidene chloride in a mixer, add defoamer and leveling agent, and stir for 20 minutes at a stirring speed of 600 rpm to make a mixture;

[0025] (3) Mix sodium polyacrylate and polyvi...

Embodiment 2

[0026] Example 2 Water-resistant interior wall putty powder is mainly prepared from the following raw materials (5 kg each): 13 parts of sodium polyacrylate, 14 parts of polyvinyl acetate, 45 parts of ash calcium powder, and 21 parts of hydroxypropyl methylcellulose , 25 parts of sepiolite, 102 parts of heavy calcium carbonate, 13 parts of polyvinylidene chloride, 22 parts of soluble starch, 1.5 parts of defoamer, and 0.8 part of leveling agent. The preparation method of above-mentioned water-resistant interior wall putty powder is:

[0027] (1) Take lime calcium powder, sepiolite and heavy calcium carbonate and place them in a grinder, crush and grind for 45 minutes, take them out and pass through a 400-mesh sieve to make raw material powder;

[0028] (2) Put hydroxypropyl methylcellulose and polyvinylidene chloride in a mixer, add defoamer and leveling agent, and stir for 36 minutes at a stirring speed of 800 rpm to make a mixture;

[0029] (3) Mix sodium polyacrylate and p...

Embodiment

[0030] Example 3 The water-resistant interior wall putty powder is mainly prepared from the following raw materials (5 kg each): 9 parts of sodium polyacrylate, 10 parts of polyvinyl acetate, 40 parts of ash calcium powder, and 17 parts of hydroxypropyl methylcellulose , 21 parts of sepiolite, 96 parts of heavy calcium carbonate, 9 parts of polyvinylidene chloride, 17 parts of soluble starch, 0.8 part of defoamer, and 0.5 part of leveling agent. The preparation method of above-mentioned water-resistant interior wall putty powder is:

[0031] (1) Take lime calcium powder, sepiolite and heavy calcium carbonate and place them in a grinder, crush and grind for 30 minutes, take them out and pass through a 330-mesh sieve to make raw material powder;

[0032] (2) Put hydroxypropyl methylcellulose and polyvinylidene chloride in a mixer, add defoamer and leveling agent, and stir for 24 minutes at a stirring speed of 650 rpm to make a mixture;

[0033] (3) Mix sodium polyacrylate and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com