Method for testing rut of rigid-flexible composite pavement structure

A composite pavement and testing method technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., to achieve good results, wide application range, and good scientific evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The described embodiments are only used to illustrate the technical solutions of the present invention, and are not intended to limit the present invention.

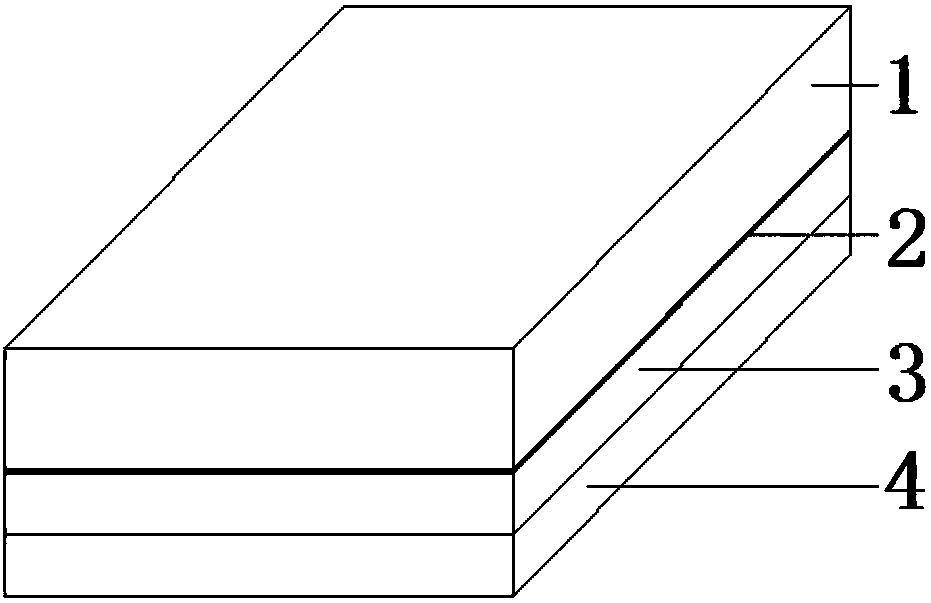

[0020] A kind of testing method of rigid-flexible composite pavement structure rutting of the present invention, carries out the test through the Hamburg rutting instrument, and the test piece is a composite test piece, refer to figure 1 As shown, the composite specimen is composed from bottom to top of SBS modified asphalt SMA-16 with a thickness of 6cm, a cement concrete panel with a thickness of 3cm, and a composite material with a thickness of 3cm as an example to prepare a composite specimen; firstly, the composite material (4) Composed of rubber powder, sand, and gravel with a single particle size, the maximum particle size...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com