A kind of composite tb rubber powder modified asphalt

A modified asphalt and composite modification technology, applied in building components, building insulation materials, buildings, etc., can solve problems such as insufficient high temperature rutting resistance, achieve good low temperature performance, solve environmental pollution, and improve high temperature rutting resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The preparation method of the above-mentioned composite TB rubber powder modified asphalt includes the following steps:

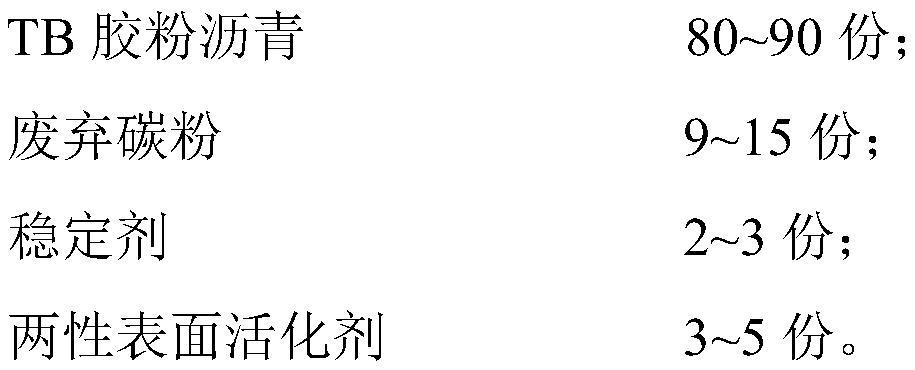

[0075] (1) Preparation: Preparation according to the raw material ratio of the TB rubber powder asphalt, waste toner, stabilizer, and amphoteric surface activator;

[0076] (2) Preprocessing: The waste toner is heated to 130 to 150 ° C, and then the waste toner ultrasonic waves will strengthen 0.5 to 1 hour under conditions of ultrasonic power of 1000 to 3000W;

[0077] (3) Composite modification: Extract the pre-treated waste carbon powder to the TB rubber powder, after each addition, stir until there is no obvious particle, then continue to add, so repeatedly until the carbon powder is added; then at 210 The mechanical mixer was stirred at ~ 230 ° C for 2 to 4 hours, and the shear machine was used to cut 1.5 to 2 hours by 1200 ± 50 r / min.

[0078] (4) Pregnancy: Add a stabilizer, surfactant, surfactant at 150 to 180 ° C, and mixed for 3 to 4 hours at...

Embodiment 1

[0081] Preparation method of composite TB rubber powder modified asphalt, as follows:

[0082] (1) Preprocessing: First heat the waste toner is heated to 130 ° C, then ultrasonic enhancement, ultrasonic power 1000W, and the radiation time is 30 min;

[0083] (2) Composite modification: 9 parts of carbon powder preprocessed into 80 parts of TB rubber powder modified asphalt, and the mechanical mixer was stirred at 220 ° C for 2 h, and then the shearing machine was scared at 1200r / min. Sliced 1.5H;

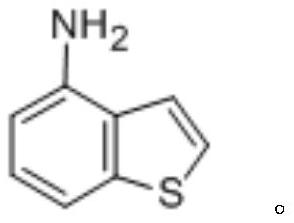

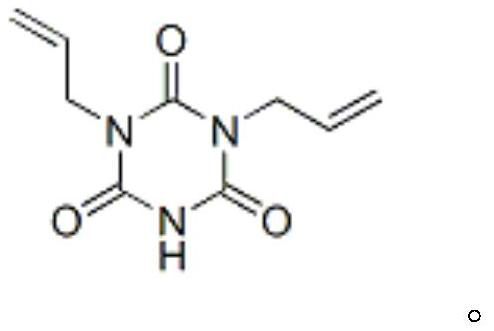

[0084] (3) Pregnancy: 2 parts of 2 parts of stabilizers (diene isocyanurate and diaminobenzamide) are added to the composite asphalt, the mass ratio of the two is 1.5) and 3 parts of the amphoteric surface activator (4 - Aminophenylene thiophene), at 160 ° C temperature, mixed mixed mixed for 3 hours, cooling to obtain a composite Tb rubber modified asphalt.

Embodiment 2

[0086] Preparation method of composite TB rubber powder modified asphalt, as follows:

[0087] (1) Preprocessing: First heating the waste toner conventional to 140 ° C, then use ultrasonic enhancement, ultrasonic power 2000W, and the radiation time is 40 min;

[0088] (2) Composite modification: 12 parts of carbon powder preprocessed into 85 parts of TB rubber powder modified asphalt, and the mechanical mixer was stirred at 220 ° C for 3 h, and then used the shearing machine to cut at 1200 r / min. Sliced 1.5H;

[0089] (3) Pregnancy: 3 parts of the composite asphalt (diethylene isocyanurate and diaminobenzamide), the mass ratio of 1.2) and 4 parts of the two-sex surface activator (4 - Aminophenylene thiophene), at 160 ° C temperature, mixed mixed mixed for 3 hours, cooling to obtain a composite Tb rubber modified asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com