Rubber asphalt modifier, modified asphalt, asphalt mixture and its preparation and application

A technology of rubber asphalt and modified asphalt, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of strong odor, serious environmental pollution, and high emission of harmful gases, and achieve low odor and excellent low-temperature bending damage Response, to achieve the effect of environmental protection production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

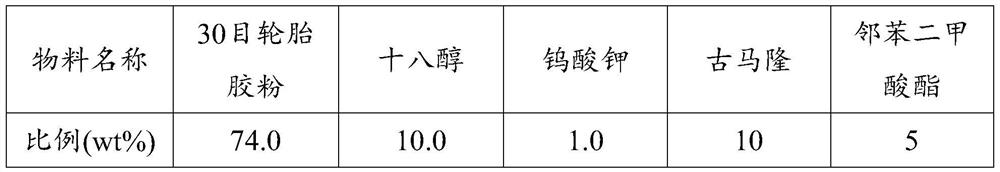

[0036] 1. The preparation process of the low-odor rubber asphalt modifier is as follows: first mix various materials in proportion through a solid powder mixer, and the proportion of materials is shown in Table 1:

[0037] Table 1 Low odor rubber modifier material composition ratio

[0038]

[0039] Feed the above-mentioned mixed materials into the twin-screw machine, control the temperature at 220-230°C, and control the plasticizing time of the materials in the screw for 10-15 minutes, so that the reaction of the fatty alcohol is complete, and the modified rubber powder can be obtained. Odor rubber asphalt modifier.

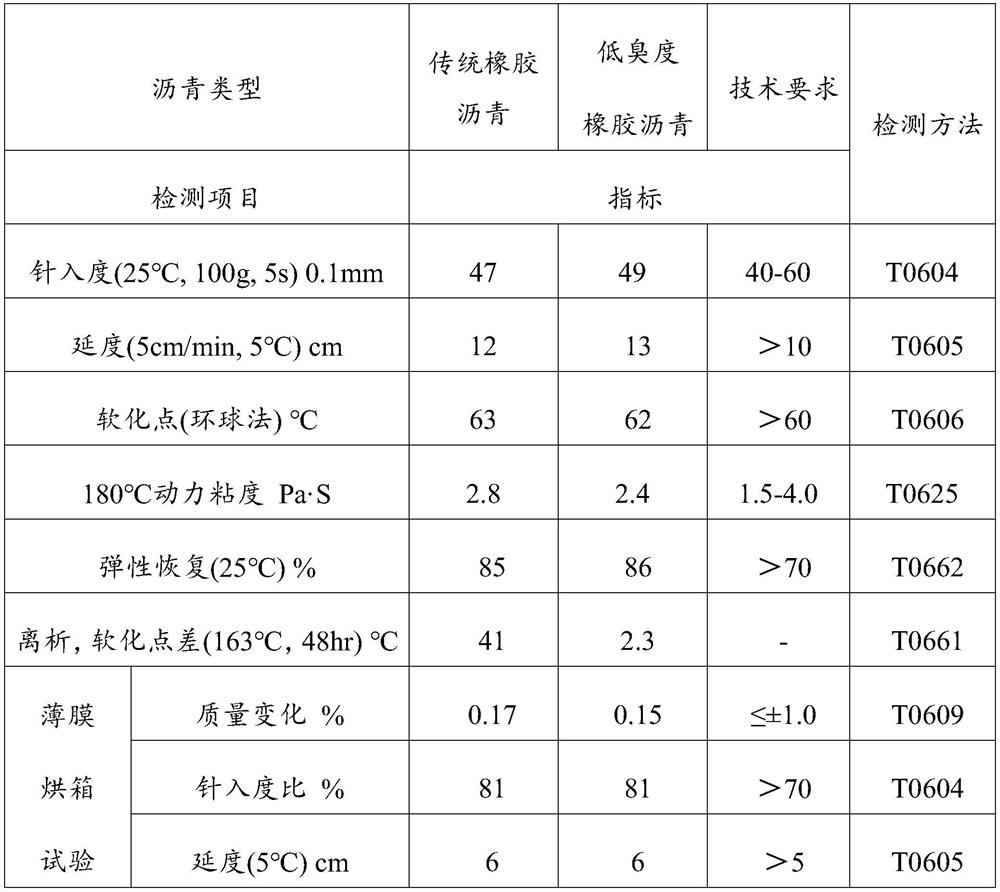

[0040] 2. The low-odor rubber asphalt prepared with the above modifiers is compared with the traditional rubber asphalt prepared with ordinary rubber powder (30 mesh tire rubber powder). The process is shown in Table 2, and the technical indicators are shown in Table 3:

[0041] Table 2 Preparation process and material comparison of different rubber asphalt ...

Embodiment 2

[0061] 1. The preparation process of the low-odor rubber asphalt modifier is as follows: firstly, mix various materials uniformly through a solid powder mixer in proportion, and the proportion of materials is shown in Table 7:

[0062] Table 7 Low odor rubber modifier material composition ratio

[0063]

[0064] Feed the above-mentioned mixed materials into the twin-screw machine, control the temperature at 220-230°C, and control the plasticization time of the materials in the screw for 10-15 minutes, so that the reaction of fatty alcohol is complete, and the modified asphalt rubber with low odor can be obtained. sex agent.

[0065] 2. Prepare low-odor rubber-modified asphalt with the above-mentioned modifier, the composition of which is 25% modifier by weight, 75% is 70# petroleum asphalt, and the preparation temperature is 190°C. The production process can reduce the emission of harmful gases such as hydrogen sulfide and sulfur dioxide, reduce the concentration of odor, ...

Embodiment 3

[0070] 1. The preparation process of the low-odor rubber asphalt modifier is as follows: firstly mix various materials in proportion through a solid powder mixer, and the proportion of materials is shown in Table 8:

[0071] Table 8 Low odor rubber modifier material composition ratio

[0072]

[0073] Feed the above-mentioned mixed materials into the twin-screw machine, control the temperature at 220-230°C, and control the plasticization time of the materials in the screw for 10-15 minutes, so that the reaction of fatty alcohol is complete, and the modified asphalt rubber with low odor can be obtained. sex agent.

[0074] 2. Prepare low-odor rubber-modified asphalt with the above-mentioned modifier, the composition of which is 25% modifier by weight, 75% is 70# petroleum asphalt, and the preparation temperature is 190°C. . The production process can reduce the emission of harmful gases such as hydrogen sulfide and sulfur dioxide, reduce the concentration of odor, and impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com