Modified asphalt prepared from waste packing tapes and preparation method of modified asphalt

A technology for modifying asphalt and tape, applied in building components, building insulation materials, buildings, etc., can solve the problems of high processing cost and complicated procedures, and achieve the effects of simple operation, obvious environment and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

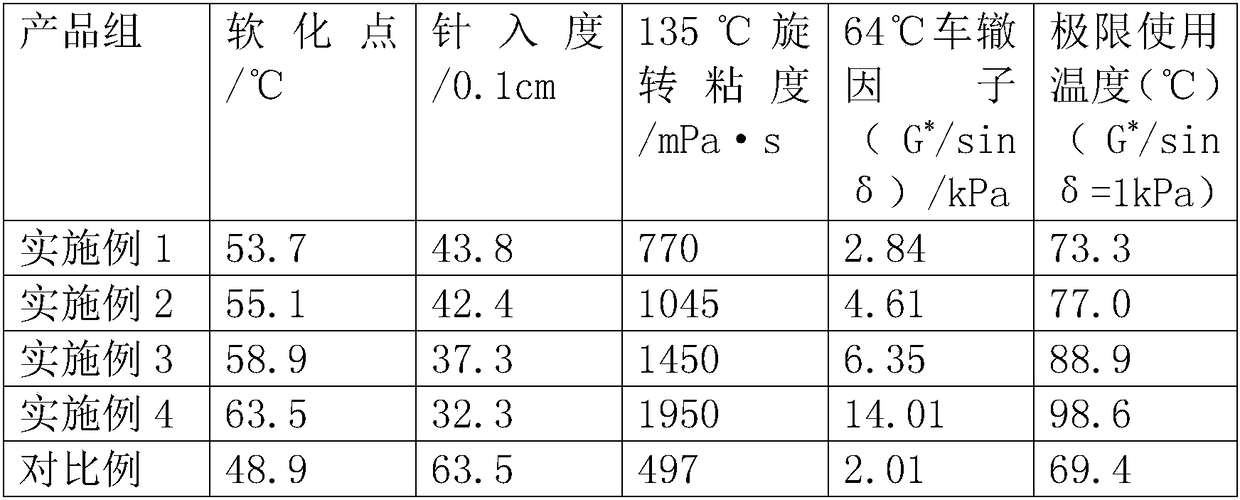

Examples

Embodiment 1

[0026] A kind of preparation method of the modified asphalt that utilizes waste sealing tape to prepare comprises the following steps:

[0027] S1. Cut the required waste sealing tape into square pieces with a side length of 2cm to 3cm;

[0028] S2. Heat the required Shell 70# matrix asphalt raw material in an oven at 135°C until it has sufficient fluidity;

[0029] S3. Add 1000g of base asphalt raw materials into the reaction vessel according to the proportion, control the temperature at 175°C to 180°C, add 20g of the waste sealing tape modifier into the reaction vessel, and manually stir with a glass rod for 10 minutes to 15 minutes ;

[0030] S4. Keep the temperature at 175°C to 180°C, and use a high-shear mixer emulsifier to shear at a high speed of 5000rpm for 45 minutes;

[0031] S5. Place the reaction container in an oven at 135°C for 20 minutes to fully swell the waste sealing tape modifier and base asphalt raw material;

[0032] S6. Keep the temperature at 175° C. ...

Embodiment 2

[0035] A kind of preparation method of the modified asphalt that utilizes waste sealing tape to prepare comprises the following steps:

[0036] S1. Cut the required waste sealing tape into square pieces with a side length of 2cm to 3cm;

[0037] S2. Heat the required Shell 70# matrix asphalt raw material in an oven at 135°C until it has sufficient fluidity;

[0038] S3. Add 1000g of matrix asphalt raw material into the reaction vessel according to the proportion, control the temperature at 175°C-180°C, add 40g of the waste sealing tape modifier into the reaction vessel, and manually stir with a glass rod for 10-15 minutes ;

[0039] S4. Keep the temperature at 175°C to 180°C, and use a high-shear mixer emulsifier to shear at a high speed of 6000rpm for 50 minutes;

[0040] S5. Place the reaction container in an oven at 135°C for 20 minutes to fully swell the waste sealing tape modifier and base asphalt raw material;

[0041] S6. Keep the temperature at 175° C. to 180° C., a...

Embodiment 3

[0044] A kind of preparation method of the modified asphalt that utilizes waste sealing tape to prepare comprises the following steps:

[0045] S1. Cut the required waste sealing tape into square pieces with a side length of 2cm to 3cm;

[0046] S2. Heat the required Shell 70# matrix asphalt raw material in an oven at 135°C until it has sufficient fluidity;

[0047] S3. Add 1000g of matrix asphalt raw material into the reaction vessel according to the ratio, control the temperature at 175°C-180°C, add 60g of the waste sealing tape modifier into the reaction vessel, and manually stir with a glass rod for 10-15 minutes ;

[0048] S4. Keep the temperature at 175°C to 180°C, and use a high-shear mixer emulsifier to shear at a high speed of 7000rpm for 55 minutes;

[0049] S5. Place the reaction container in an oven at 135° C. for 25 minutes to fully swell the waste sealing tape modifier and base asphalt raw material;

[0050]S6. Keep the temperature at 175° C. to 180° C., and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com