Method for using high-aluminium coal ash to synthesize composite xonotlite insulation material

A technology of composite thermal insulation material and high-alumina fly ash, which is applied in the direction of silicate, aluminum silicate, alkaline earth metal silicate, etc., can solve the problems of waste of resources, environmental pollution of high-alumina fly ash, etc., and achieve easy operation , good prospects for popularization and application, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

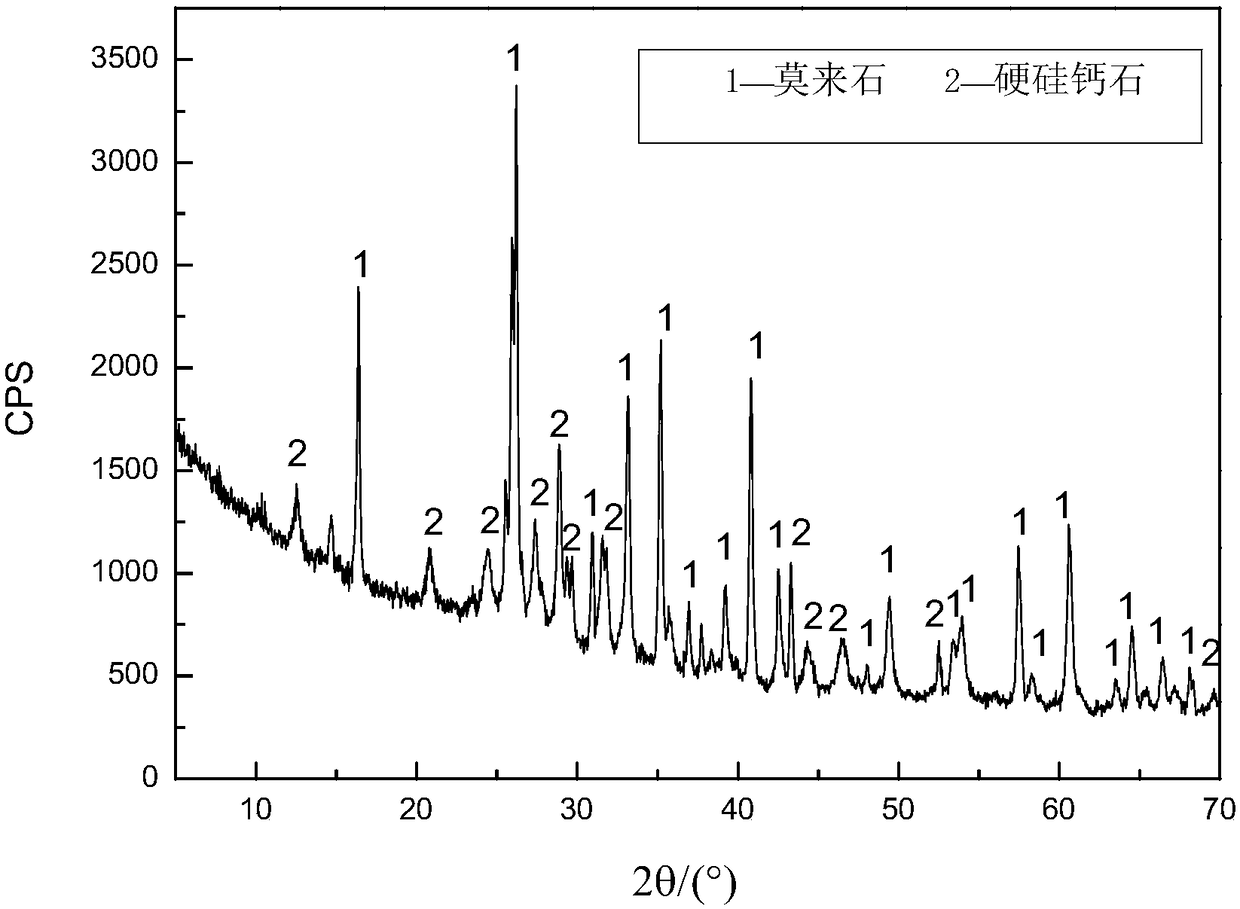

Image

Examples

Embodiment 1

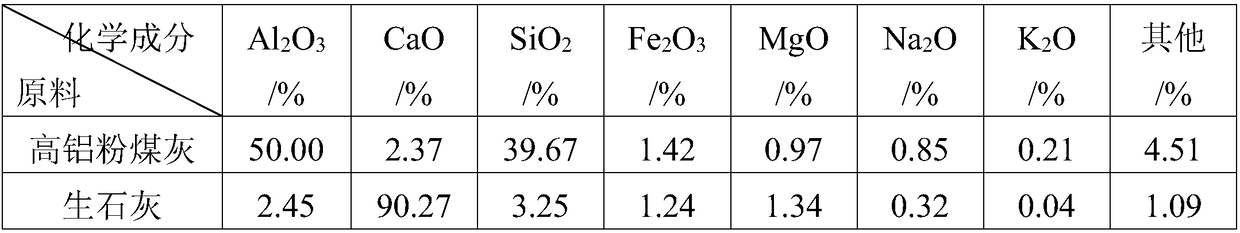

[0025] The high-alumina fly ash used in this example was taken from a power plant in Hohhot, Inner Mongolia, and the quicklime was taken from Qingshuihe County, Hohhot, Inner Mongolia. The chemical composition is shown in Table 1.

[0026] Table 1 Chemical composition of high alumina fly ash and quicklime

[0027]

[0028] The mullite and xonotlite type composite thermal insulation and fireproof material in this embodiment is made by mixing 65kg of the above-mentioned high-alumina fly ash and 35kg of the above-mentioned quicklime, and then using a ball mill to grind it until all particle sizes are less than 0.12mm, and then adding 0.5 kg of barium chloride and 0.6 kg of aluminum chloride, then add 2022 kg of water according to the liquid-solid ratio of 20 and mix them evenly, then put them into a high-pressure reactor, control the reaction temperature to 230 ° C, and the reaction pressure to 2.83 MPa, 90-100 Insulate at ℃ for 60 minutes, at 150°C for 30 minutes, at 180°C fo...

Embodiment 2

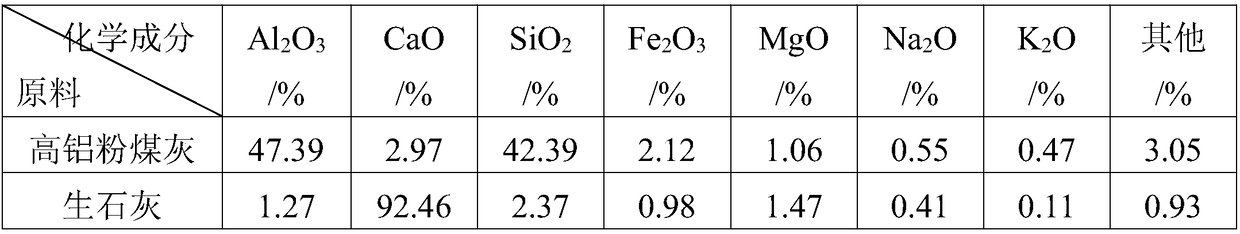

[0033] The high-aluminum fly ash used in this example was taken from a power plant in Shuozhou City, Shanxi Province, and the quicklime was taken from a Lime Factory in Shuozhou City, Shanxi Province. The chemical composition is shown in Table 2.

[0034] Table 2 Chemical composition of high alumina fly ash and quicklime

[0035]

[0036] The mullite and xonotlite type composite thermal insulation and fireproofing material in this embodiment is made by mixing 62kg of the above-mentioned high-alumina fly ash and 38kg of the above-mentioned quicklime, and then using a ball mill to grind it until all particle sizes are less than 0.08mm, and then add 0.7 kg of aluminum chloride, 0.8 kg of aluminum sulfate and 1.2 kg of barium chloride, then according to the liquid-solid ratio of 15, add 1540.5 kg of water and mix evenly, then put them into a high-pressure reactor, control the reaction temperature to 250 ° C, and the reaction pressure to be 4.11MPa, heat at 90-100°C for 60min, h...

Embodiment 3

[0041] The high-alumina fly ash used in this example was taken from a power plant in Shuozhou City, Shanxi Province, and the chemically pure quicklime was taken from Tianjin Huadong Reagent Factory. The chemical composition is shown in Table 3.

[0042] Table 3 Chemical composition of high aluminum fly ash and quicklime

[0043]

[0044] The mullite and xonotlite type composite thermal insulation and fireproofing material in this embodiment is made by mixing 68kg of the above-mentioned high-alumina fly ash and 32kg of the above-mentioned quicklime, and then using a ball mill to grind it until all particle sizes are less than 0.08mm, and then add 0.4 kg of aluminum nitrate, 0.6 kg of barium sulfate and 1.0 kg of sodium sulfate, and then according to the liquid-solid ratio of 12, add 1224 kg of water and mix evenly, then put them into a high-pressure reactor, control the reaction temperature to 215 ° C, and the reaction pressure to 2.13 MPa, 90-100°C for 60min, 150°C for 30mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com