Liquid crystal display screen manufacture process and its apparatus

A liquid crystal display and process technology technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of low production capacity of the process technology, and achieve the effect of shortening transportation time, shortening operation time, and improving work efficiency and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

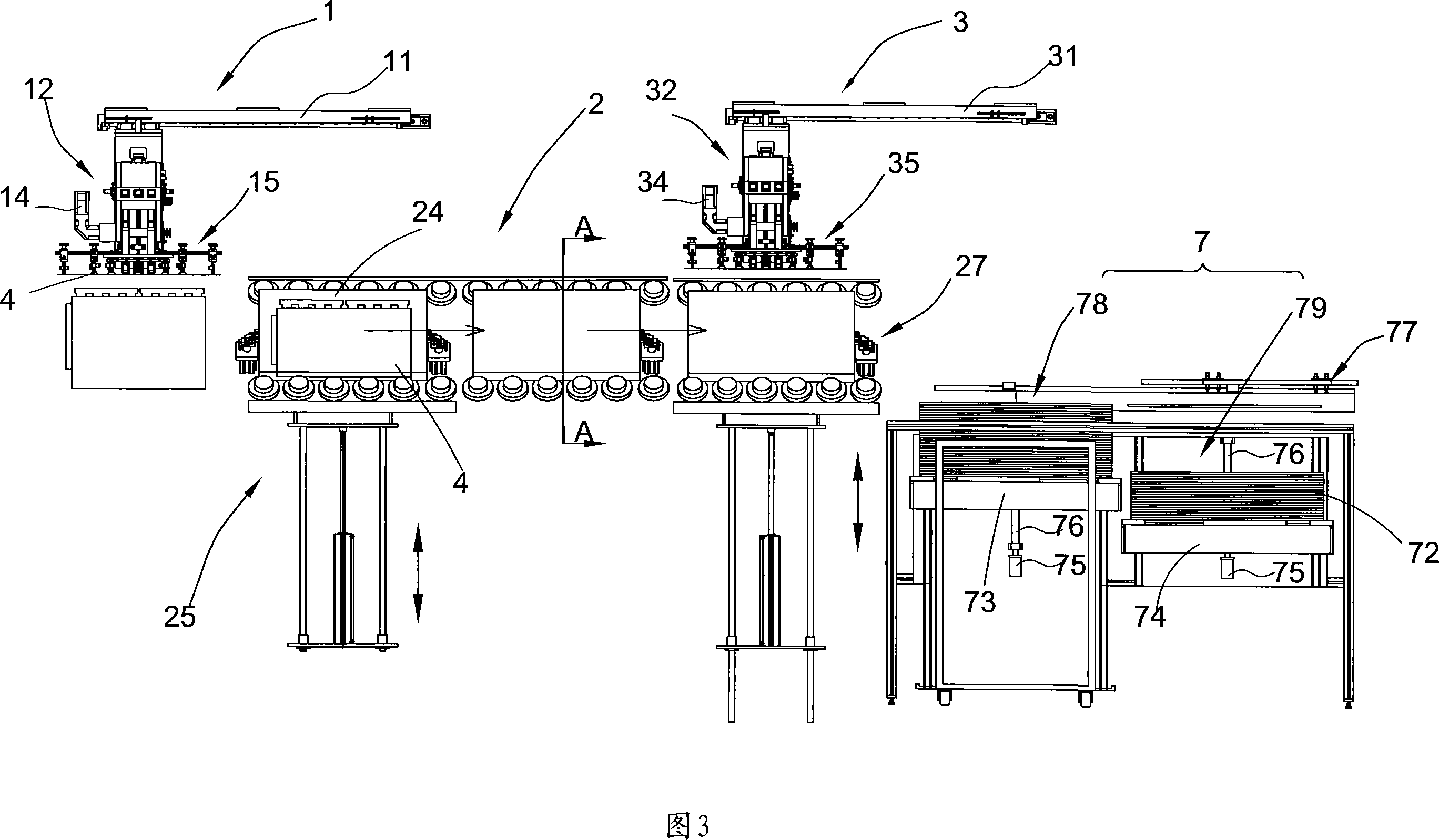

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

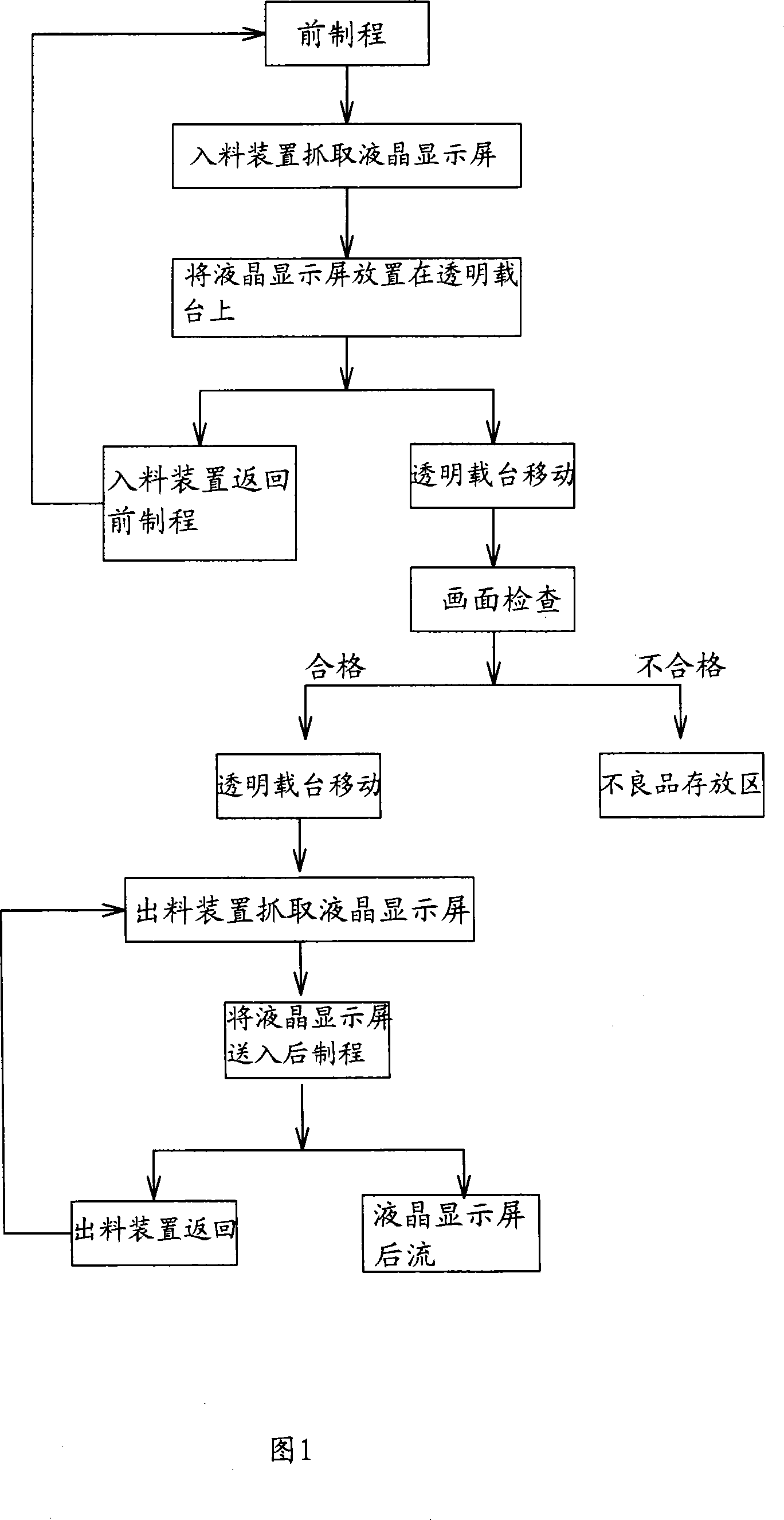

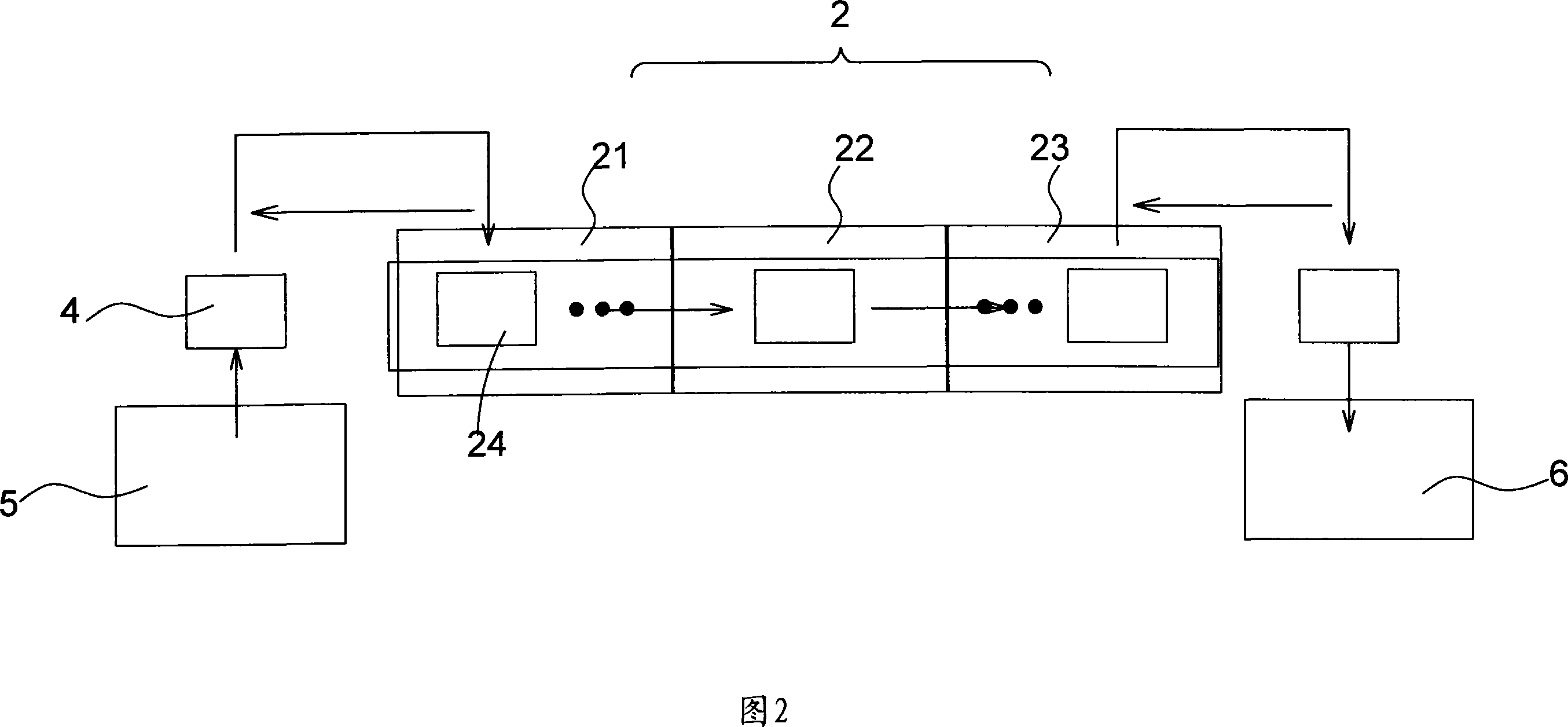

[0036] Accompanying drawing 1 is the flowchart of liquid crystal display process technology of the present invention, and it mainly comprises the following steps:

[0037] a. The feeding device 1 grabs the liquid crystal display 4 produced by the previous process 5;

[0038] b, the feeding device 1 places the above-mentioned liquid crystal display screen 4 on the empty transparent carrier 24 in the feeding area 21 of the assembly line 2, and the feeding area 21 is located at the upstream of the detection station 22, so that the The liquid crystal display screen 4 of detection station 22;

[0039] c. The feeding device 1 returns to step a to grab the next liquid crystal display, the transparent carrier 24 moves to the detection station 22, and the transparent carrier 24 is located on the liquid crystal display 4 and the backlight unit 41;

[0040] d, detecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com