Underground continuous wall pipeline in-situ protection construction method

An underground diaphragm wall and pipeline technology, which is applied in the field of engineering technology and science, can solve the problems of large impact on project construction period, heavy coordination workload, and no obstacles, etc., so as to solve the problem of ground wall framing and translation, save construction cost, shorten The effect of project duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

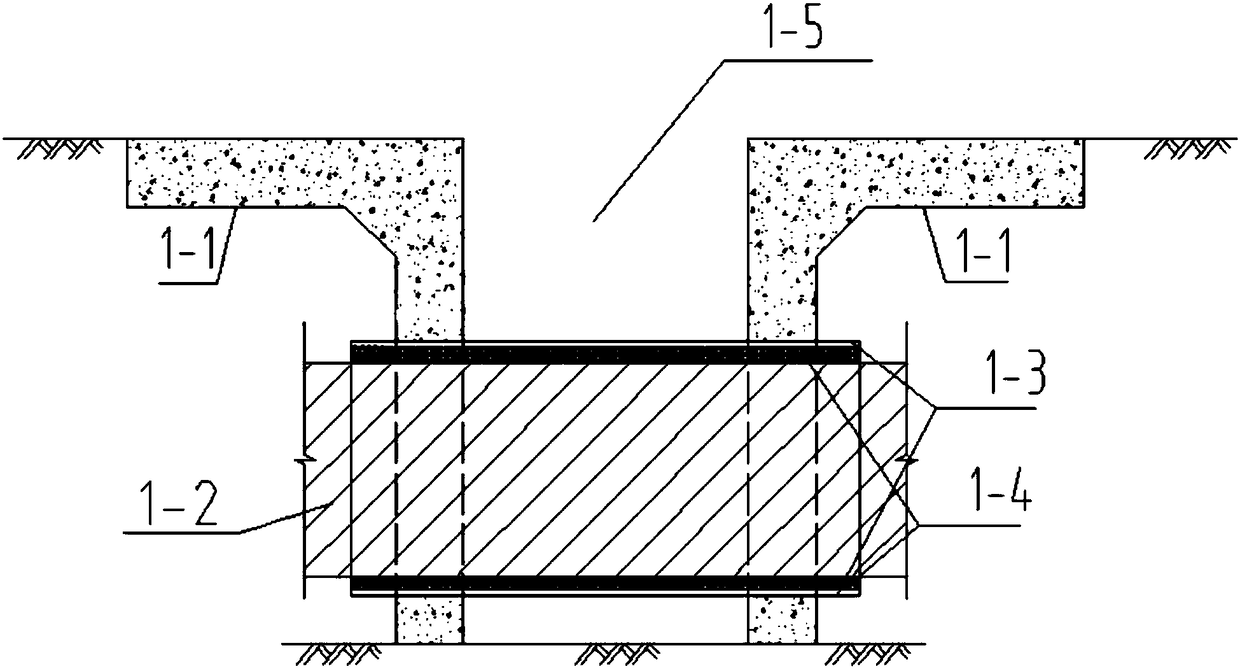

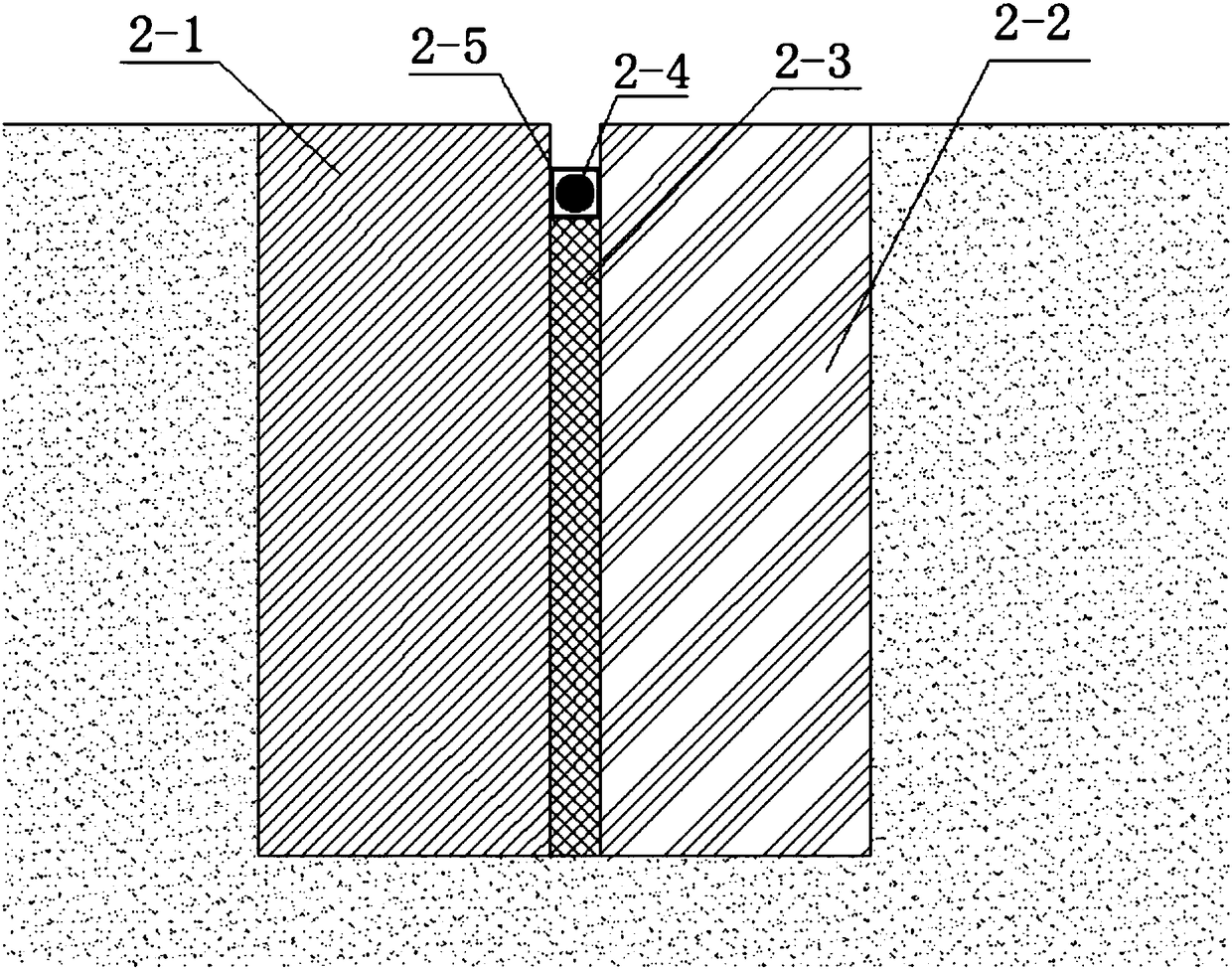

[0035] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

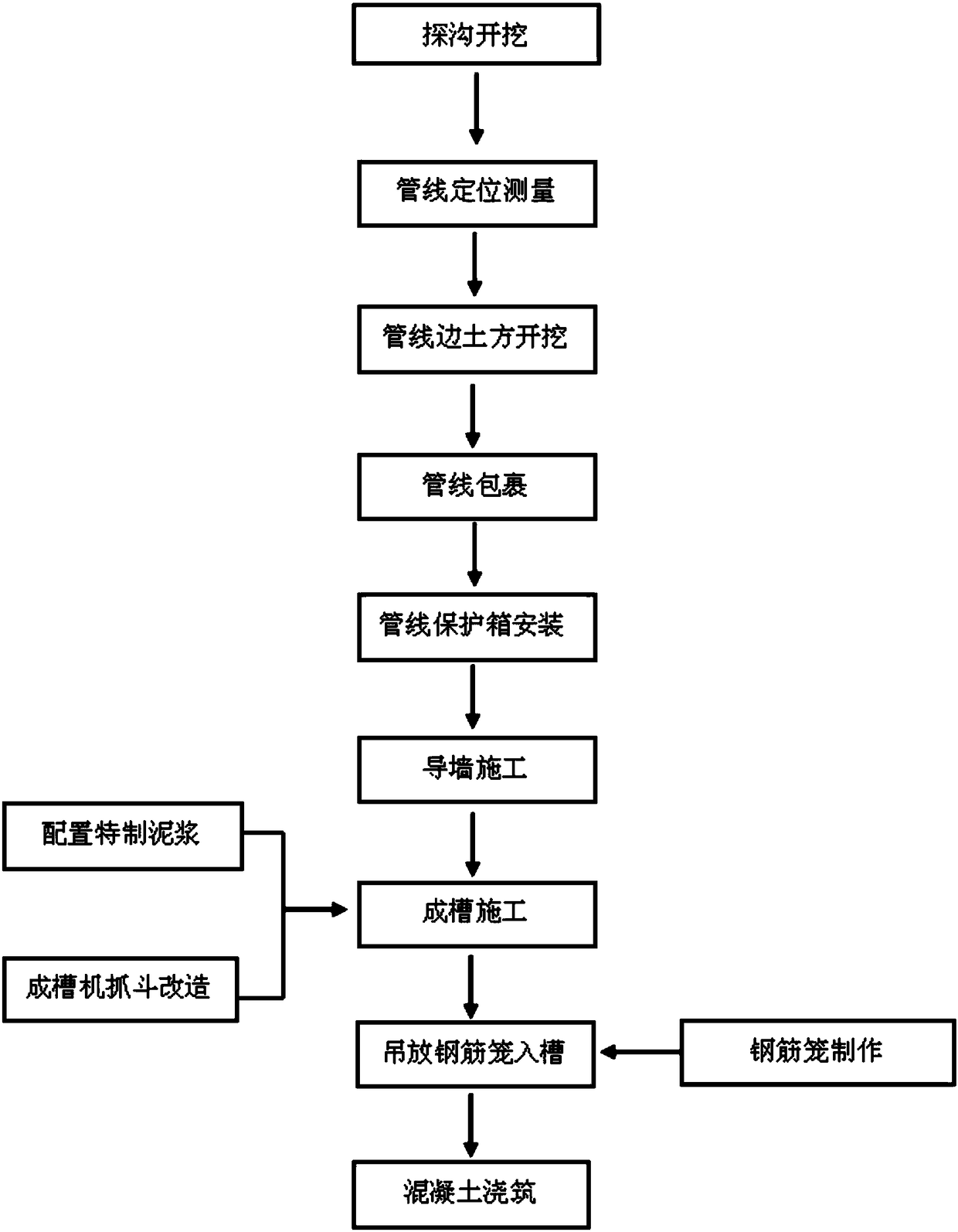

[0036] see Figure 1-8 , a method for in-situ protection construction of underground diaphragm wall pipelines, the method is specifically as follows:

[0037] A. Trench excavation: According to the pipeline 1-2 distribution map, the pipeline trench excavation is carried out, and the type, direction, buried depth and width of the pipeline are initially ascertained;

[0038] B. Pipeline positioning measurement: use a total station and a steel ruler to accurately measure and locate the buried depth, width, height, upper and lower surface elevations and direction of the pipeline;

[0039] C. Excavation of earthwork beside the pipeline: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com