Forging method of H13 steel vertical continuous casting round billet

A technology for continuous casting of round billets and continuous casting billets, which is used in the manufacture of tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc. problems, to achieve the effect of eliminating carbide precipitation, reducing production costs, and shortening production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: A kind of forging method of vertical continuous casting round billet of H13 steel, with φ400*2500mm continuous casting billet, forging into φ185mm round steel as an example, the specific forging method includes the following steps:

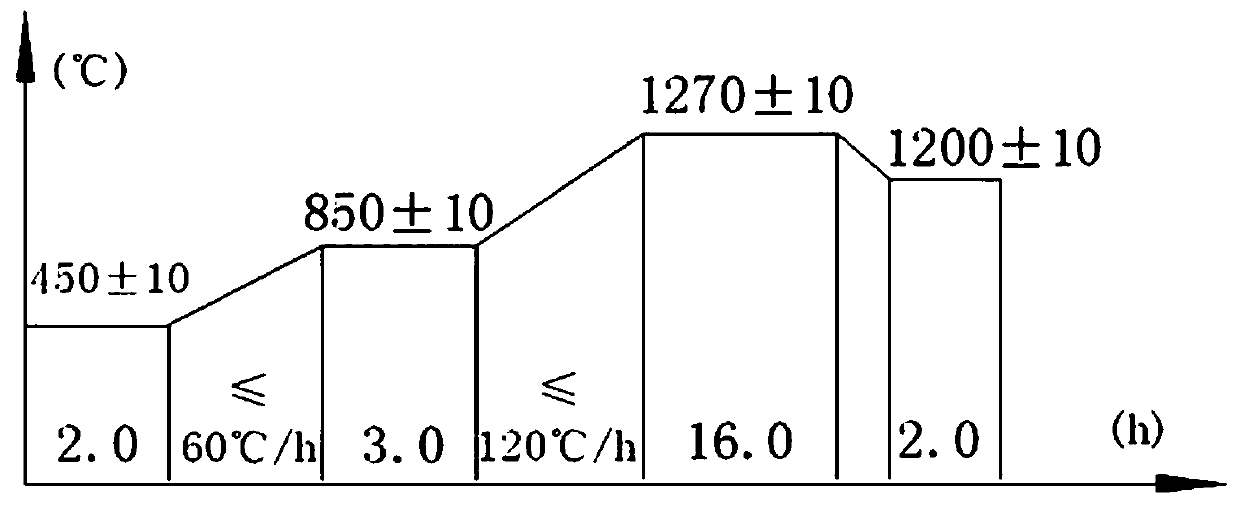

[0018] Step 1), design the pre-forging heating specification for the φ400*2500mm continuous casting slab, see the heating specification figure 1 , first keep warm at a temperature of 450±10°C for 2.0 hours, then raise the temperature to 850±10°C at a rate of ≤60°C / h and then keep warm for 3.0 hours, then heat up at a rate of ≤120°C / h Keep warm at 1270±10°C, the holding time is 16.0h, the trolley is pulled out to air-cool the material for 20min, the trolley is pulled in and the furnace door is closed, the furnace temperature is set at 1200±10°C, the holding time is 3.0h, and the furnace is forged after holding the heat;

[0019] The purpose of this kind of heat preservation at a high temperature of 1270±10°C is to reduce or eli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com