Production method capable of reducing dendritic segregation of hot rolled coiled plate Q345B

A technology of Q345B and dendrite segregation, applied in the production field of reducing Q345B dendrite segregation of hot-rolled coils, can solve problems such as toughness reduction, heat treatment solid solution strengthening failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The chemical composition weight percent of the hot-rolled coil Q345B of the present invention is as follows: C: 0.12%, Mn: 0.59%, Si: 0.12%, P: 0.020%, S: 0.010%, Al s : 0.010%, Cr: 0.7%, the rest is iron and unavoidable impurities.

[0025] Mechanical properties: yield strength 431MPa, tensile strength 545MPa, impact energy 187J, elongation (%) 27.5.

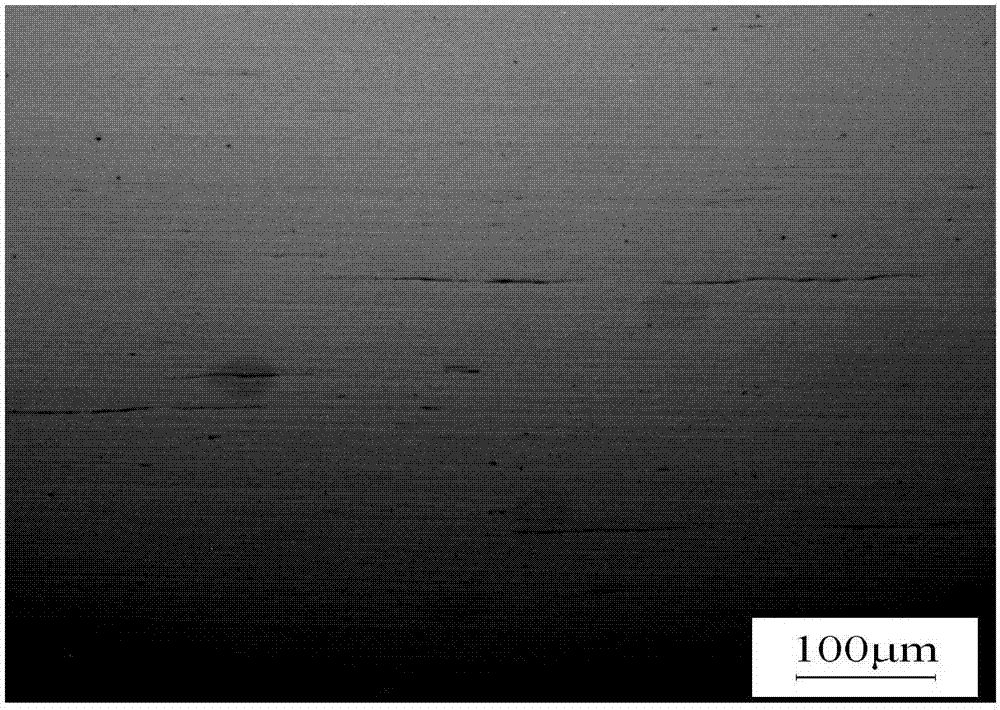

[0026] Metallographic analysis: grain grade / grade 11.5, banded structure / grade 0.5.

[0027] Effect evaluation: the structure is uniform and fine, the strength and toughness are high, the level of type A inclusions is low, the size is 60 μm, and the level of band structure is reduced.

Embodiment 2

[0028] Embodiment 2: The chemical composition weight percent of the hot-rolled coil Q345B of the present invention is as follows: C: 0.06%, Mn: 0.4%, Si: 0.15%, P: 0.021%, S: 0.011%, Al s : 0.005%, Cr: 1.0%, and the rest are iron and unavoidable impurities.

[0029] Mechanical properties: yield strength 416MPa, tensile strength 527MPa, impact energy 197J, elongation (%) 28.

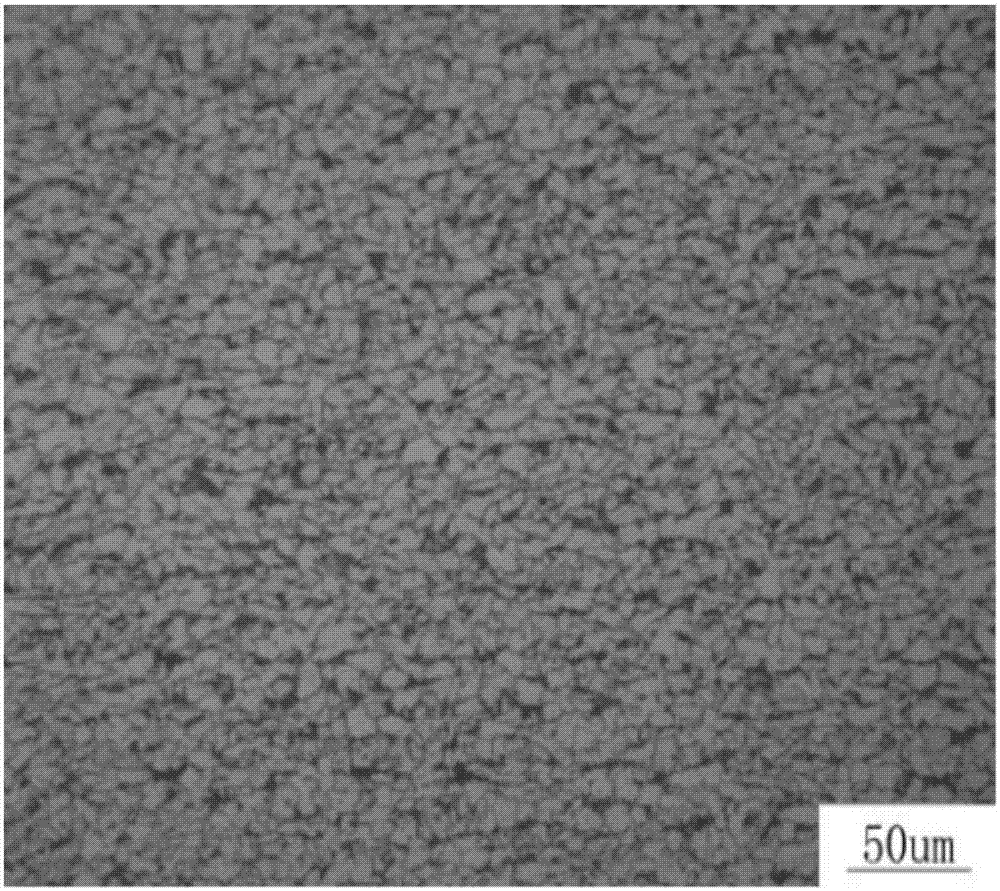

[0030] Metallographic analysis: grain grade / grade 11, band structure / grade 0.5.

[0031] Effect evaluation: the structure is uniform and fine, the strength and toughness are high, the level of type A inclusions is low, the size is 60 μm, and the level of band structure is reduced.

Embodiment 3

[0032] Example 3: The chemical composition weight percent of the hot-rolled coil Q345B of the present invention is as follows: C: 0.08%, Mn: 0.487%, Si: 0.111%, P: 0.019%, S: 0.012%, Al s : 0.005%, Cr: 0.862%, N: 0.010%, and the rest are iron and unavoidable impurities.

[0033] Mechanical properties: yield strength 445MPa, tensile strength 564MPa, impact energy 206J, elongation (%) 27.4.

[0034] Metallographic analysis: grain grade / grade 11.5, banded structure / grade 0.5.

[0035] Effect evaluation: the structure is uniform and fine, the strength and toughness are high, the level of type A inclusions is low, the size is 60 μm, and the level of band structure is reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com