Secondary-cooling reduction convex foot roll structure for bloom and reduction technology

A technology of blooms and foot rolls, which is applied in the field of convex foot roll structure and reduction technology for secondary cold reduction of blooms, can solve the problems of limited application effect, achieve improved reduction effect, good slab segregation and center porosity, The effect of improving the support ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

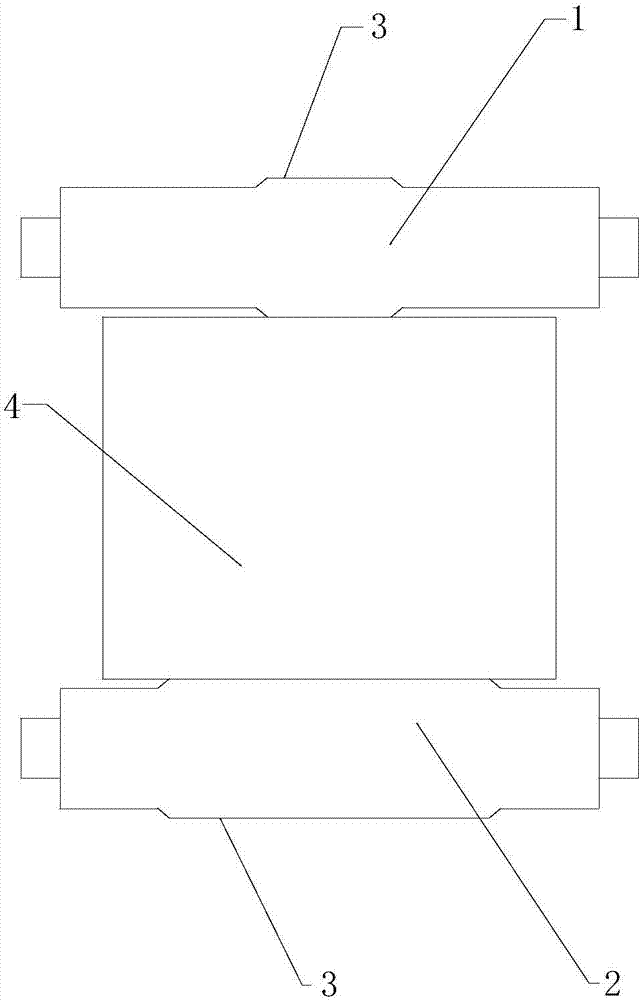

[0031] This embodiment is applied to a 360mm×450mm bloom continuous casting machine, which has 12 tension levelers, including 10 compressive tension levelers, mainly for the production of medium and high carbon alloy steels such as bearing steel and heavy rail steel.

[0032] In the convex roll structure of the drawing and leveling machine used for continuous casting of blooms in this embodiment, the upper and lower foot rolls are convex rolls, the first frame of the drawing and leveling machine has an upper roll boss of 3220 mm, and a lower roll boss of 3280 mm. Foot roller boss 3 all reduces 30mm up and down on each frame.

[0033] The convex roll of the tension leveling machine of this embodiment is carried out according to the following steps when the bloom continuous casting is pressed down:

[0034] For bearing steel, there are 5 sets of compression and straightening machines. Under the condition of pulling speed of 0.45m / min, the reductions of 2#-6# pulling and straight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com