Straight-through submerged nozzle with stirring effect

A straight-through, immersion-type technology, applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve various problems that cannot be solved, have no stirring effect, cannot achieve the effect of stirring molten steel, etc., and achieve suitable Good for promotion, simple structure and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

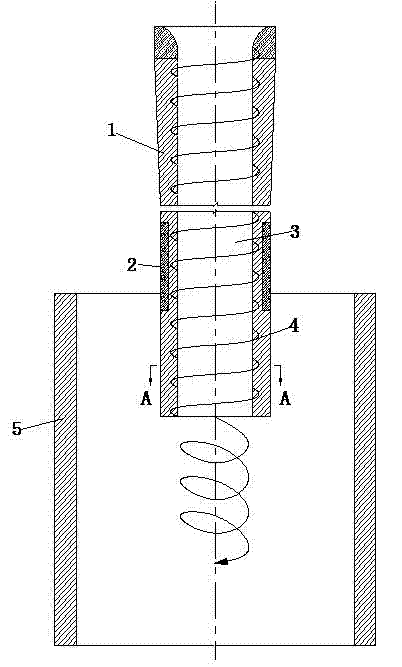

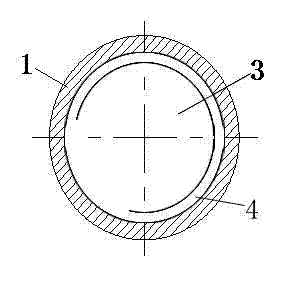

[0020] See attached figure 1 , a straight-through submerged nozzle with a stirring effect, comprising a tubular body 1 that penetrates up and down, the body 1 defines an inner cavity 3, and a slag line 2 is provided on the outside of the side wall of the body 1, and the depth of the slag line 2 is 10-25mm, height 100-160mm, the distance between the lower end and the end of the nozzle is 30-100mm. The inner surface of the side wall is provided with a continuous spiral groove 4 from the opening end of the top of the body to the outlet end of the bottom of the body. The width of the upper surface of the spiral groove 4 is 20mm, the depth is 20mm, and the cross section in the depth direction is triangular. Of course, this The spiral groove at the center can also be rectangular or trapezoidal, the pitch of the spiral groove 4 is 50 mm, the cross-sections of the body 1 and the inner cavity 3 are circular, the side wall thickness of the body 1 is 40 mm, and the diameter of the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com