On-line calibration method for opening of wide and thick plate continuous casting machine soft-reduction segment

A verification method and technology of opening degree, which is applied in the field of online verification of the opening degree of the fan-shaped section under light reduction of wide and thick plate continuous casting machines, can solve the problems of large differences and unsuitable for verification, etc., to improve low-fold quality and reduce The effect of loosening the center and eliminating the cracks in the middle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

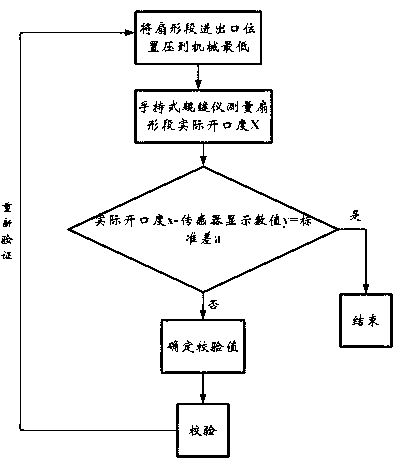

Method used

Image

Examples

Embodiment 1

[0063] 1) Continuous casting machine equipment parameters: straight arc-shaped slab continuous casting machine, radius 9.5m; continuous casting machine includes bending section and 18 fan-shaped sections, of which fan-shaped 7th and 8th sections are straightening sections, 9-18 sections are horizontal sections, Adopt standard deviation a=0.4mm.

[0064] 2) The billet size is 250mm×1820mm, the steel type is Q690D, the total amount of light reduction is 8mm, the total shrinkage value of the sector roll gap is 17mm, and the light reduction intervals are 8 sectors, 9 sectors, and 10 sectors, a total of 3 Sector. The steel composition, casting temperature and casting speed are shown in Table 1.

[0065]

[0066] 3) The size and set reduction of the cold slab are shown in Table 2.

[0067]

[0068] It can be seen from Table 2 that after the online segment opening degree check is adopted before pouring Q690D, the roll gap reduction of the segment can be accurately implemented...

Embodiment 2

[0073] 1) The equipment parameters of the continuous casting machine are as in Example 1, and the standard deviation a=0.4mm is adopted.

[0074] 2) The billet size is 250mm×2000mm, the steel type is Q235B, the total light reduction is 8mm, the total shrinkage value of the roll gap of the continuous casting machine is 16mm, and the reduction interval is 7 sectors, 8 sectors, and 9 sectors, totaling 3 sector segment. The steel composition, casting temperature and casting speed are shown in Table 4.

[0075]

[0076] 3) The size and set reduction of the cold slab are shown in Table 5.

[0077]

[0078] It can be seen from Table 5 that after the online segment opening degree check is adopted before pouring Q235B, the roll gap reduction of the segment can be accurately implemented. By tracking the conventional inspection blanks after the online sector opening degree calibration, it is found that the blanks with a deviation of 0.5mm from the set roll gap can reach 100%, and...

Embodiment 3

[0083] 1) The equipment parameters of the continuous casting machine are as in Example 1, and the standard deviation a=0.4mm is adopted.

[0084] 2) The billet size is 300mm×1820mm, the steel type is Q460C, the total amount of light reduction is 9mm, the total shrinkage value of the roll gap of the continuous casting machine is 16.1mm, and the reduction interval is sector 7, sector 8 and sector 9 in total 3 sector segments. The steel composition, casting temperature and casting speed are shown in Table 7.

[0085]

[0086] 3) The size of the cold slab and the set reduction are shown in Table 8.

[0087]

[0088] It can be seen from Table 8 that after casting Q460 with the online segment opening degree check, the roll gap reduction of the segment can be accurately implemented. By tracking the conventional inspection blanks after the online sector opening degree calibration, it is found that the blanks with a deviation of 0.5mm from the set roll gap can reach 100%, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com